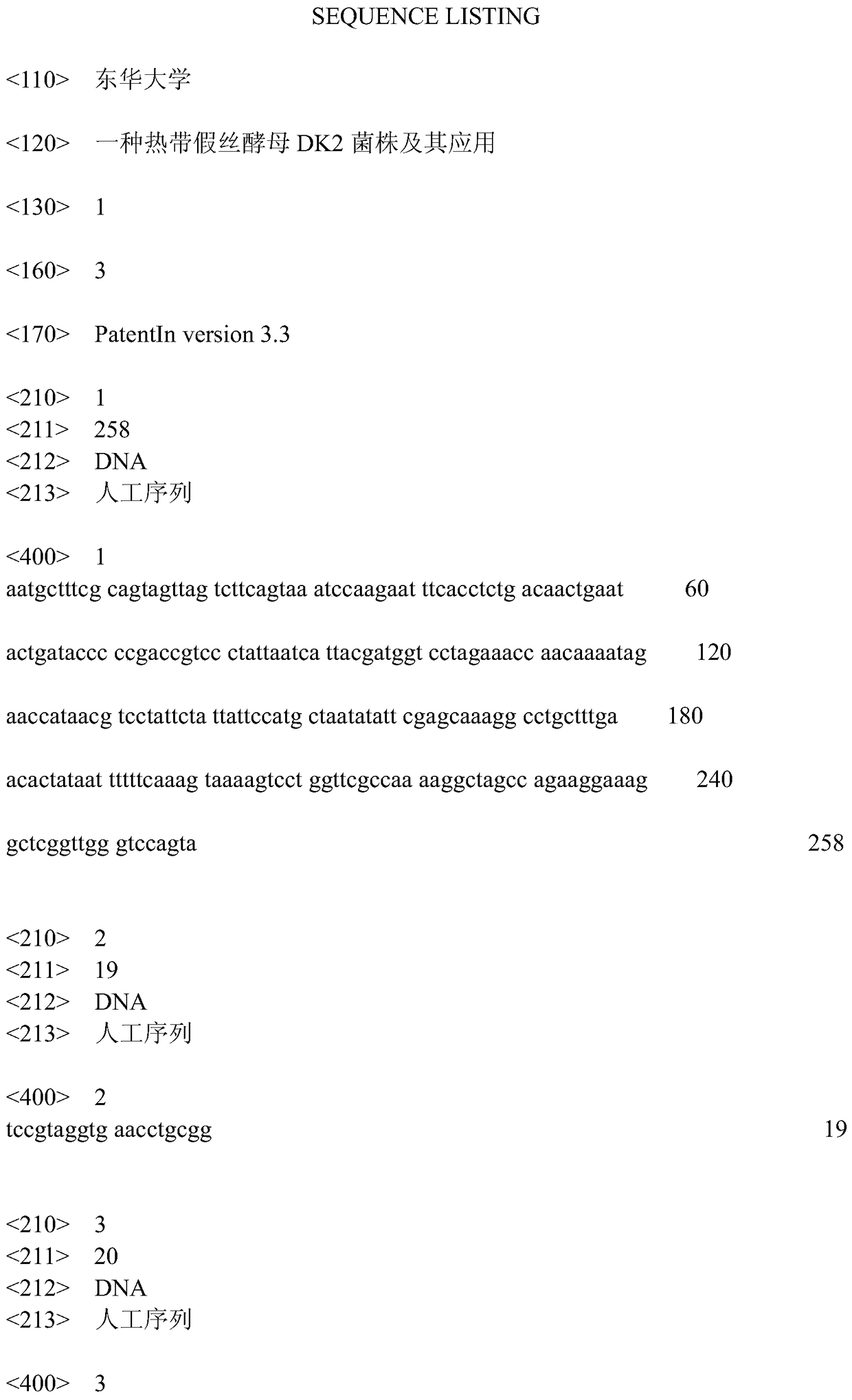

A kind of candida tropicalis dk2 bacterial strain and application thereof

A technology of Candida tropicalis and strains, which is applied to fungi, bacterial retting, microorganisms, etc., can solve the problems of high energy consumption of chemical degumming process, unrecyclable waste water, and large equipment loss, etc., and achieves high degumming efficiency and degumming. Short cycle time, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Screening method for retting or scouring strains of hemp fiber and bamboo fiber:

[0040] (1) Decomposed hemp and its soil were obtained from the retting base, and the decomposed hemp and its soil and the PDA medium were placed in the PDA medium at a ratio of 1 g: 20 ml, and enriched for 10 days. Then take 0.1ml of the PDA culture and apply it to the separation medium, and culture it statically at 30°C for 1-4 days to obtain a wild-type biologically treated high-quality strain.

[0041] (2) Inoculate the bacterial strain obtained in step (1) into PDA medium, and culture at 30° C. for 72 hours. Add freezing buffer and store at -80°C.

[0042] Described step (1) PDA medium formula is: potato 200g, glucose 20g, agar 15g, distilled water 1000mL, pH is natural.

[0043] The formula of step (2) per 100ml of freezing buffer: potassium dihydrogen phosphate 0.1g, dipotassium hydrogen phosphate 0.02g, sodium citrate 0.06g, magnesium sulfate heptahydrate 0.03g, glycerol 12ml, ad...

Embodiment 2

[0046] Utilize the method for preparing laccase from Candida tropicalis DK2 strain:

[0047] (1) Candida tropicalis DK2 strain is stored in PDA medium, and freezing buffer is added;

[0048](2) Into the sterilized and cooled 50ml PDA medium, insert the bacterium ring obtained in step (1), shake the flask at a rotating speed of 200rpm at 30°C for 24 hours; after cultivating the 50ml shake flask, inoculate the culture medium Add 5L of flax, jute or kenaf fermentation medium, and shake the flask for 24 hours under the conditions of a rotating speed of 200r / min and a temperature of 30°C to obtain a fermentation broth;

[0049] (3) Centrifuge the fermentation broth obtained in step (3) at 4° C. at 8,000 r / min, and take the supernatant, which is laccase. Then determined by spectrophotometry, the laccase activity is 10-30IU / ml, and the enzyme activity is relatively stable at pH 5.0-6.0 and 20-60°C.

[0050] Enzyme activity assay method, using guaiacol as laccase substrate, and meas...

Embodiment 3

[0052] The retting process of flax, jute or kenaf is as follows:

[0053] (1) Preserve Candida tropicalis DK2 strain in PDA medium (per 1000ml medium includes 200g potato, 20g glucose, 15g agar, 1000mL distilled water) and add freezing buffer. The formula of every 100ml of freezing buffer of described step: potassium dihydrogen phosphate 0.1g, dipotassium phosphate 0.02g, sodium citrate 0.06g, magnesium sulfate heptahydrate 0.03g, glycerin 12ml, add water and be settled to 100ml, prepare have to.

[0054] (2) Insert a ring of bacteria into 1000ml of flax, jute or kenaf bran medium (per 1000ml medium includes 200g of flax, jute or kenaf bran, 50g of bran, 50ml of wort and 950ml of water), shake the flask Culture, the culture condition is 30°C, the pH is natural, and the culture time is 24 hours;

[0055] (3) Inoculate the culture medium into flax, jute or kenaf bran fermentation medium (every 1000ml culture medium includes flax, jute or kenaf bran 100g, bran 100g, wort juice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com