Lithium ion secondary battery composite positive material and preparation method thereof

A composite positive electrode material and secondary battery technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as structural damage, rapid capacity decay, and loss of the meaning of coating, and achieve effective coating and good Electronic conductance and mechanical strength, and the effect of suppressing side reactions at the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

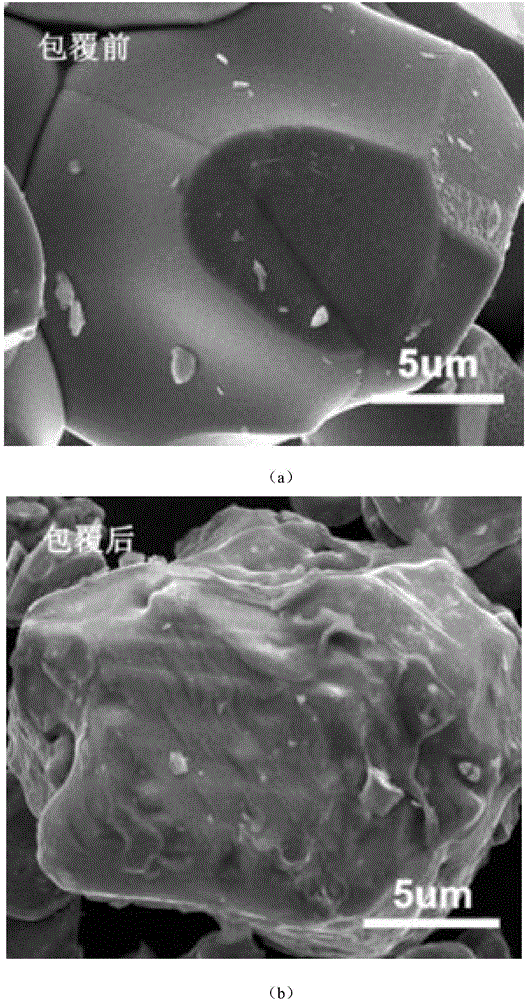

[0032] Lithium cobalt oxide (LiCoO 2 ) SEM image before coating as image 3 (a) shown.

[0033] Add 1.0g of polyacrylonitrile powder to 80ml of N,N-dimethylformamide, heat and stir in an oil bath at 60°C until a transparent solution is formed, then add 100g of lithium cobaltate to the above solution, and place in an oil bath at 150°C Stirring was continued and the solvent was evaporated to dryness. The powder obtained after evaporating the solvent was placed in a muffle furnace for treatment at 400°C / 0.5h, the heating rate was 5°C / min, and the treatment atmosphere was air (the volume fraction of oxygen was about 25%).

[0034] Lithium cobaltate (LiCoO 2 ) after coating SEM as attached image 3 (b) shown.

[0035] The UV-Vis absorption spectrum of the polyacrylonitrile coating after being treated at different temperatures (250°C and 400°C) for 0.5h, as shown in Figure 4 As shown, the variation of the absorption peak with different temperatures in the figure indicates the...

Embodiment 2

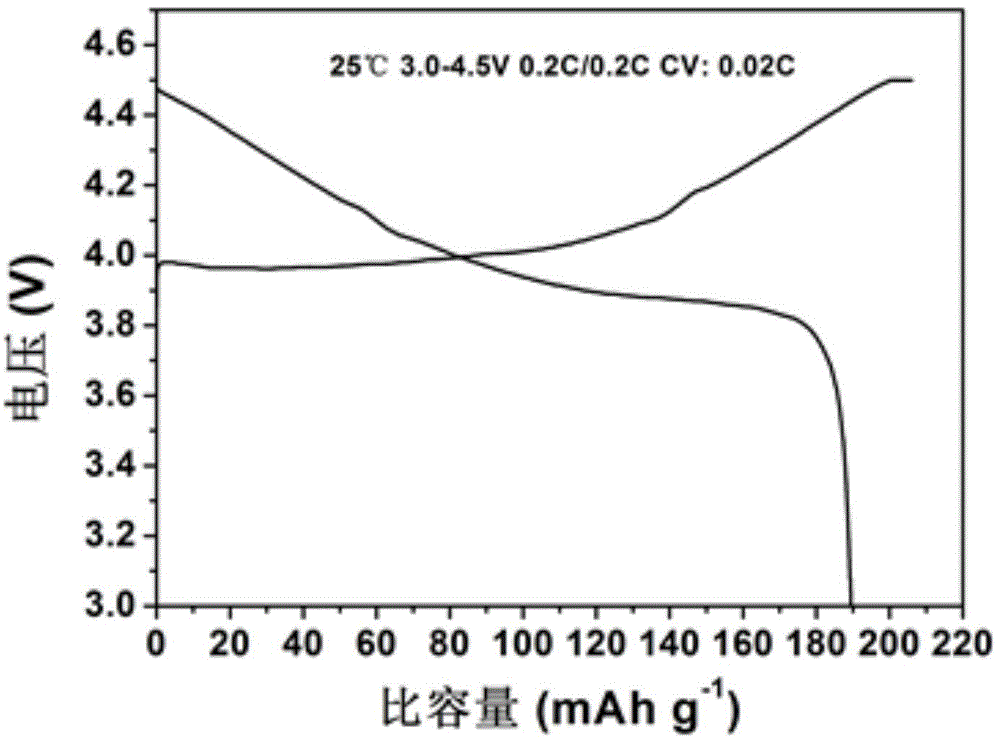

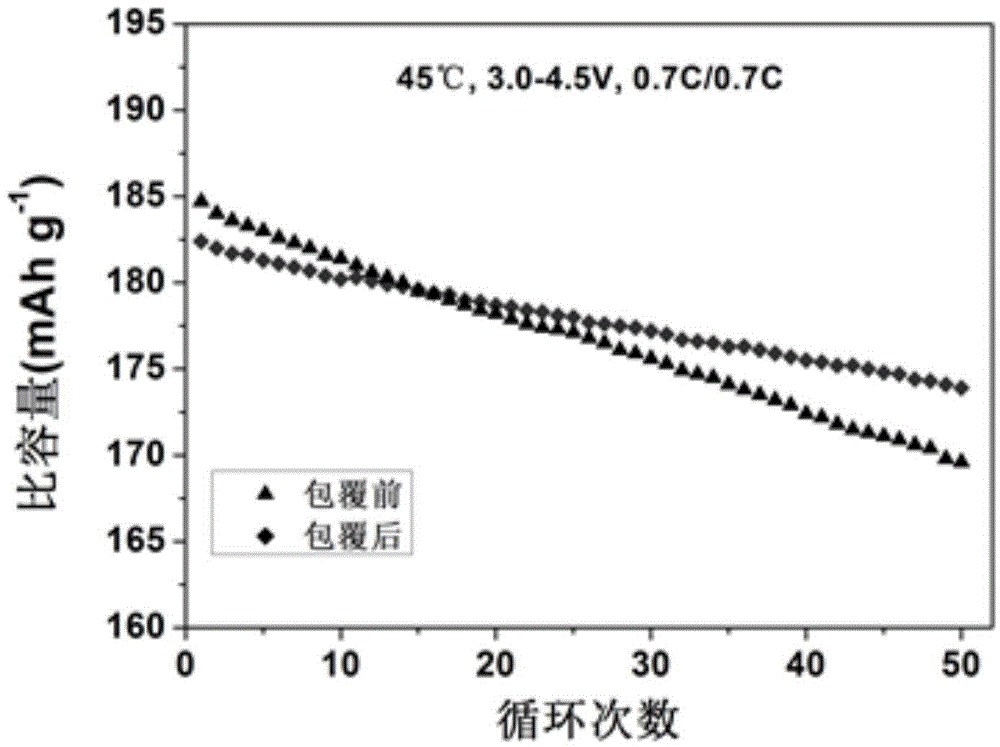

[0038]Add 1.0g of polyacrylonitrile powder to 80ml of N,N-dimethylformamide, heat and stir in an oil bath at 60°C until a transparent solution is formed, then add 100g of lithium cobaltate to the above solution and continue to stir to form a uniform suspension. The above suspension was spray dried to remove N,N dimethylformamide. The powder obtained after spray drying was placed in a muffle furnace for treatment at 400 °C / 0.5 h, the heating rate was 5 °C / min, and the treatment atmosphere was air. Using N-methylpyrrolidone as a solvent, stir the powder obtained after sintering with conductive carbon black and polyvinylidene fluoride according to the mass ratio of 90:5:5, and then coat it on the surface of clean aluminum foil, and scrape it to form a film. After blast drying, the electrode sheets were punched into discs with a diameter of 8 mm, and further dried in a vacuum oven at 120° C. for 6 hours to remove moisture. Use the prepared electrode sheet as the working electrode...

Embodiment 3-5

[0040] In the same manner as in Example 1, the lithium cobaltate was replaced by lithium nickelate, lithium manganate, and lithium nickel-cobalt manganate in turn, and the prepared electrode sheet was used as the working electrode of the half-cell, and lithium metal was used as the counter electrode. / L LiPF 6 / Ethylene carbonate (EC)-dimethyl carbonate (DMC) (mass ratio of EC and DMC 1:1) is used as electrolyte, is assembled into battery in glove box and carries out charge and discharge test to its battery, and the voltage range is 3.0-4.5V, charge and discharge current density is 0.2C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com