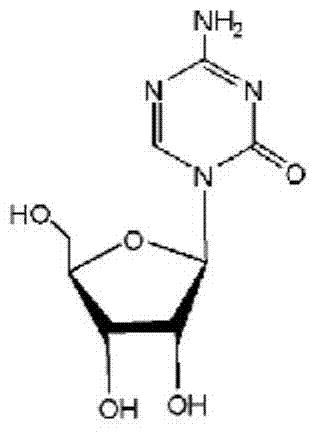

Azacitidine freeze-dried preparation and preparation method thereof

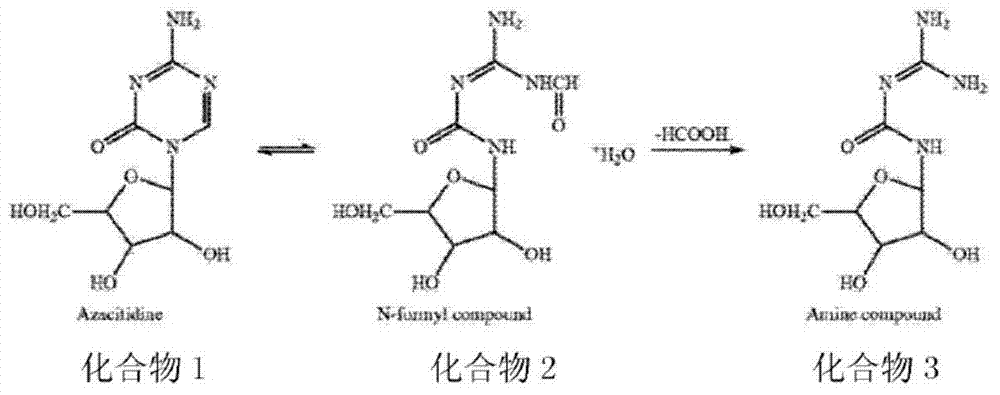

A technology for azacitidine and freeze-dried preparations, which is applied in the field of azacitidine freeze-dried preparations and preparations, can solve the problems of high residue, unsatisfactory, unfavorable quality assurance, etc., achieve good physical and chemical stability, and reduce product-related problems. Substances, the effect of ensuring product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

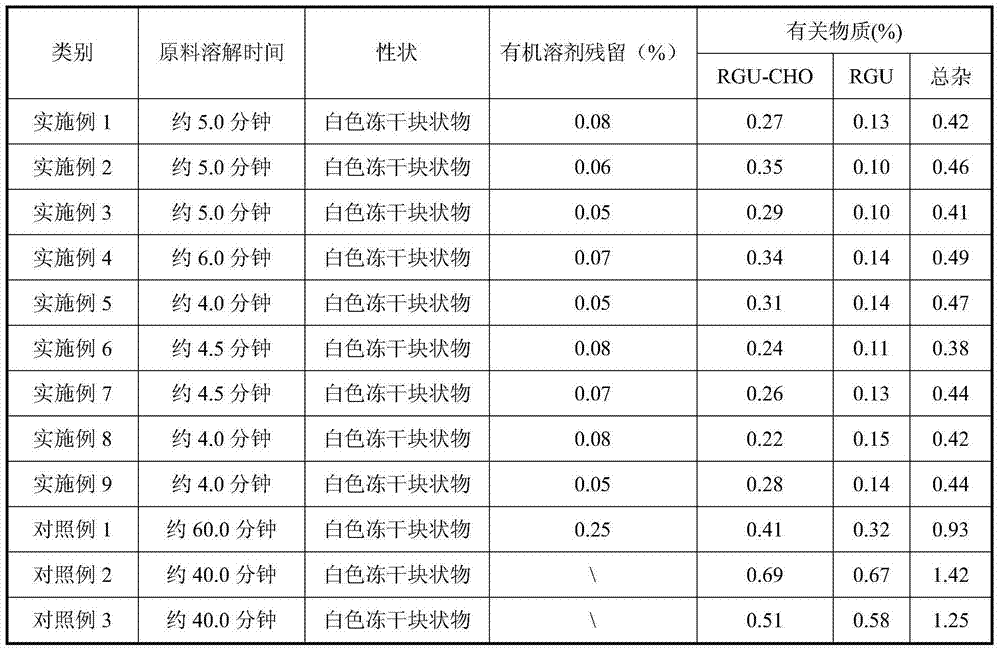

Examples

Embodiment 1

[0039] Measure 950ml water for injection, cool to -3~-1℃, weigh 5g mannitol and dissolve it in the above water for injection, weigh 5g azacitidine, stir and disperse azacitidine into 20ml ethanol, and dissolve azacitidine After the cytidine ethanol dispersion and water for injection are mixed and dissolved, add water to 1000ml, stir the material and filter it with a 0.22μm microporous membrane. The filtered solution is divided into glass bottles, 20ml / piece, and freeze-dried to obtain azacitidine Freeze-dried powder.

Embodiment 2

[0041] Measure 950ml water for injection, cool to -3~-1℃, weigh 5g mannitol and dissolve in the above water for injection, weigh 5g azacitidine, stir and disperse azacitidine in 20ml isopropanol, After mixing the isopropanol dispersion of azacitidine with water for injection, add water to 1000ml, stir the material and filter it with a 0.22μm microporous membrane. The filtered solution is divided into glass bottles, 20ml / piece, freeze-dried Obtain azacitidine freeze-dried powder.

Embodiment 3

[0043] Measure 950ml water for injection, cool to -3~-1℃, weigh 5g mannitol and dissolve in the above water for injection, weigh 5g azacitidine, stir and disperse azacitidine into 20ml methanol, and dissolve azacitidine After mixing the methanol dispersion of cytidine with water for injection, add water to 1000ml, stir the material and filter it with a 0.22μm microporous membrane. The filtered solution is divided into glass bottles, 20ml / piece, and freeze-dried to obtain azacytosis. Glycoside freeze-dried powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com