Composite nutritional type lick brick for Tibetan sheep and preparation method thereof

A nutritious, brick-licking technology, applied in application, animal feed, animal husbandry, etc., can solve the problems of reduced nutritional value, low hardness, low crude protein and ash content of pasture, and achieve the goal of promoting the development of reproductive organs and improving production. Performance, the effect of a wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The raw materials are composed of 14% corn flour, 5% wheat bran, 7% rapeseed meal, 17% molasses, 10% urea, 17% table salt, 3% calcium hydrogen phosphate, 1.5% calcium carbonate, and 3% baking soda. %, sodium bicarbonate 1.5%, coated compound multidimensional 0.65%, rumenin 0.35%, Portland cement 13%, bentonite 6%, premix 1%; the premix is composed of the following components by weight percentage: Take 5% of ferrous sulfate, 3.3% of copper sulfate, 9% of manganese sulfate, 7% of zinc sulfate, 0.1% of sodium selenite, 0.8% of potassium iodide, 0.4% of cobalt chloride, and 74.4% of bentonite.

[0031] Follow the steps below to prepare the required lick tiles:

[0032] (1) take raw material by weight percent component;

[0033] (2) Take corn flour, wheat bran and rapeseed meal, pulverize them and mix well, the pulverization fineness is 18 mesh;

[0034] (3) Get bentonite in table salt, baking soda, baking soda, calcium carbonate, calcium hydrogen phosphate, coated compo...

Embodiment 2

[0044] The raw materials are composed by weight percentage: corn flour 15%, wheat bran 6%, rapeseed meal 5%, molasses 14.5%, urea 8%, salt 16%, calcium hydrogen phosphate 1.2%, calcium carbonate 2.5%, baking soda 5% %, 1% sodium bicarbonate, 0.8% coated compound multidimensional, 0.5% rumenin, 8.5% bentonite, 15% cement, 1% premix; Iron 6%, copper sulfate 3.25%, manganese sulfate 12%, zinc sulfate 9.5%, sodium selenite 0.3%, potassium iodide 0.9%, cobalt chloride 0.55%, bentonite 67.5%.

[0045] The preparation steps and method are the same as in Example 1.

Embodiment 3

[0047] The raw materials are composed by weight percentage: corn flour 18%, wheat bran 8%, rapeseed meal 4%, molasses 13%, urea 7%, salt 12%, calcium hydrogen phosphate 1%, calcium carbonate 2.5%, baking soda 6% %, 0.5% sodium bicarbonate, 1% coated compound multidimensional, 0.5% rumenin, 16% Portland cement, 9.5% bentonite, 1% premix; the premix is composed of the following components by weight percentage: Take 8% ferrous sulfate, 2.1% copper sulfate, 15% manganese sulfate, 11% zinc sulfate, 0.5% sodium selenite, 1.1% potassium iodide, 0.6% cobalt chloride, and 61.7% bentonite.

[0048] The preparation steps and method are the same as in Example 1.

[0049] The licking brick that the present invention produces is as shown in table 1 through testing nutrient composition:

[0050] Table 1. Nutrient composition list of compound nutritional licking bricks for Tibetan sheep

[0051]

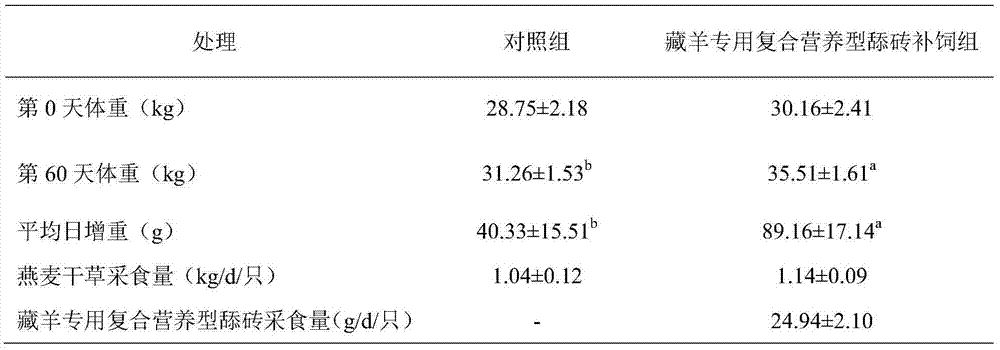

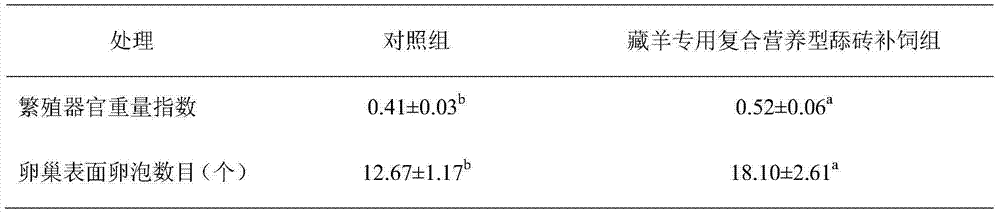

[0052] The growth performance test of Tibetan sheep and the reproductive organ developmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com