Chitosan-calcium hydroxide composite and its preparation and application as stiffener for paper

A technology of calcium hydroxide and composite materials, applied in textiles, papermaking, papermaking, paper coatings, etc., can solve the problems of limited enhancement of paper mechanical properties, increased cost of reinforcing agent, increased difficulty of spraying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

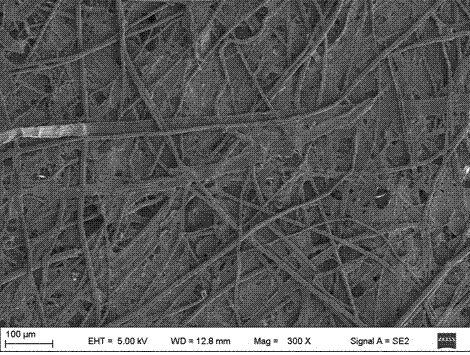

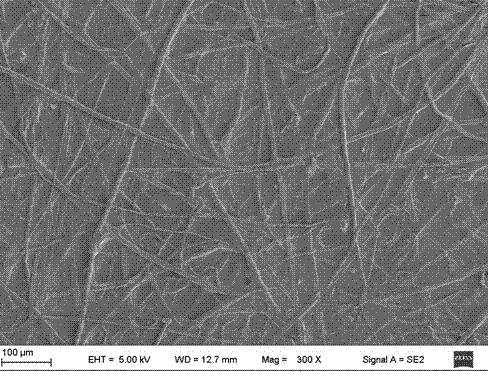

Image

Examples

Embodiment 1

[0026] (1) Preparation of calcium hydroxide: Add 4.1625g of calcium chloride to 50mL of ethylene glycol, and stir at 70°C for 20min at a speed of 800rpm to obtain an ethylene glycol solution of calcium chloride. At 150~180°C, add 50mL of 1.5mol / L NaOH solution dropwise (drop at a rate of 0.5 mL / min) to the above-mentioned ethylene glycol solution of calcium chloride, and stir at 800rpm for 15min , After cooling to room temperature, suction filtration at 0.06MPa to obtain a filter cake. Put the filter cake in 100mL isopropanol, disperse for 30min at ultrasonic power of 150W and temperature of 60°C, centrifuge at 10000rpm for 15min, collect the lower sediment, repeat the above steps 4 times, and then put the lower sediment at -60 Freeze-dry at ℃ and 3Pa for 24 hours to obtain calcium hydroxide. The prepared calcium hydroxide has a particle size of 746nm and a particle size distribution of 0.305.

[0027] (2) Preparation of chitosan solution: Weigh 480mg of chitosan, put it in ...

Embodiment 2

[0032] (1) Preparation of calcium hydroxide: Add 1.3875g of calcium chloride to 50mL of ethylene glycol, and stir at 80°C for 30 min at 400 rpm to obtain an ethylene glycol solution of calcium chloride. At 150°C, add 50 mL of 0.5 mol / L NaOH solution dropwise (dropping at a rate of 0.8 mL / min) to the above-mentioned ethylene glycol solution of calcium chloride, stir at 1000 rpm for 30 min, and cool After reaching room temperature, suction filter at 0.08 MPa to obtain a filter cake. Put the filter cake in 80 mL of isopropanol, disperse for 60 minutes at an ultrasonic power of 180 W, and a temperature of 50 ° C, then centrifuge at a speed of 9000 rpm for 10 minutes, collect the lower layer of sediment, repeat the above steps 5 times, and then put the lower layer of sediment in - Freeze-dry at 55°C and 1Pa for 12 to 24 hours to obtain calcium hydroxide. The particle size of the prepared calcium hydroxide is 631nm, and the particle size distribution is 0.163.

[0033] (2) Prepara...

Embodiment 3

[0038] (1) Preparation of calcium hydroxide: Add 2.775g of calcium chloride to 50mL of ethylene glycol, and stir at 90°C for 15min at a speed of 600rpm to obtain an ethylene glycol solution of calcium chloride. At 180°C, add 50mL of 1mol / L NaOH solution dropwise (drop at a rate of 1 mL / min) to the above-mentioned ethylene glycol solution of calcium chloride, and stir at 500rpm for 15-40min, After cooling to room temperature, suction filter at 0.07MPa to obtain a filter cake. Put the filter cake in 90mL of isopropanol, disperse for 45min at ultrasonic power of 100~180W, temperature of 55°C, centrifuge at 8000rpm for 20min, collect the lower precipitate, repeat the above steps 3 times, and finally put the lower precipitate in Freeze-dry at -50°C and 5Pa for 18 hours to obtain calcium hydroxide. The particle size of the prepared calcium hydroxide is 678nm, and the particle size distribution is 0.223.

[0039] (2) Preparation of chitosan solution: weigh 600mg of chitosan, put it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com