Method for treating organic phosphorus in wastewater

A technology for treating wastewater and organic phosphorus, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. Application and other issues, to achieve the effect of not easy to lose, high recovery rate, and reduce the content of inorganic phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

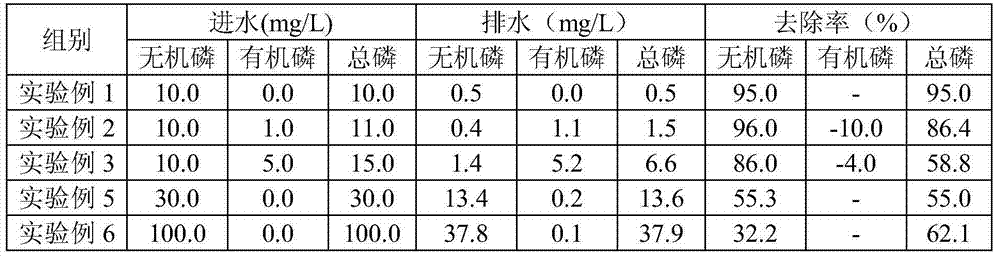

Examples

Embodiment 1

[0029] The observation period of this embodiment is 3 months.

[0030] The wastewater of a fine chemical factory is rich in organic phosphorus, and its total phosphorus concentration is about 90-100 mg / L; the organic phosphorus concentration (total phosphorus concentration-inorganic phosphorus concentration) is about 55-60 mg / L. The waste water is directly passed into the biochemical reaction unit, and the biochemical reaction unit is a plug-flow structure. The biochemical reaction unit contains microorganisms, and the existence of microorganisms in the biochemical reaction unit is similar to activated sludge. The microorganisms mainly include methane oxidizing bacteria, followed by nitrifying bacteria, nitrosifying bacteria, denitrifying bacteria, anammox bacteria, etc. The concentration of suspended bacteria is about 6000mgMLSS / L. The methane gas comes from the anaerobic facility of the enterprise wastewater, and is passed into the biochemical treatment unit through jet aer...

Embodiment 2

[0037] The observation period of this embodiment is 3 months.

[0038] The wastewater of a fine chemical factory is rich in organic phosphorus, the total phosphorus concentration is about 1600-1800mg / L; the organic phosphorus concentration is about 1400-1500mg / L. The waste water is directly passed into the biochemical reaction unit. The biochemical reaction unit contains microorganisms, which exist in the biochemical reaction unit through the biological fluidized bed method (that is, the microorganisms grow on the surface of the filler in the form of a biofilm). The microorganisms mainly include methane oxidizing bacteria, followed by nitrifying bacteria and nitrosifying bacteria. , denitrifying bacteria, anammox bacteria, aerobic heterotrophic bacteria. The converted concentration of mixed bacterial biofilm is about 12000mgMLSS / L. Methane comes from utility natural gas, and oxygen-containing gas comes from electrolytic oxygen production and fan oxygen supply respectively. ...

Embodiment 3

[0045] The observation period of this embodiment is 3 months.

[0046] The wastewater of a fine chemical factory is rich in organic phosphorus, the concentration of organic phosphorus is about 180-200mg / L, and the inorganic phosphorus is not detected. The waste water is directly passed into the biochemical reaction unit. The biochemical reaction unit contains microorganisms, and the microorganisms grow on the surface of the mobile suspended biological filler. Microorganisms mainly include methane oxidizing bacteria, followed by nitrifying bacteria, nitrosifying bacteria, denitrifying bacteria, anammox bacteria and aerobic heterotrophic bacteria. The concentration of suspended sludge is about 12000mg / L, the concentration of filler-attached sludge is about 10000-22000mg / L, and the concentration of total microorganisms is about 22000-34000mg / L. The methane gas and oxygen-containing gas are passed into the biochemical reaction unit. The methane gas is natural gas after desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com