Preparation method of novel fluorescent PVC wire/cable shield material

A wire and cable and sheath material technology, which is applied in the field of preparation of new fluorescent PVC wire and cable sheath materials, and can solve the problems that PVC cable sheath materials do not have fluorescent or luminescent properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

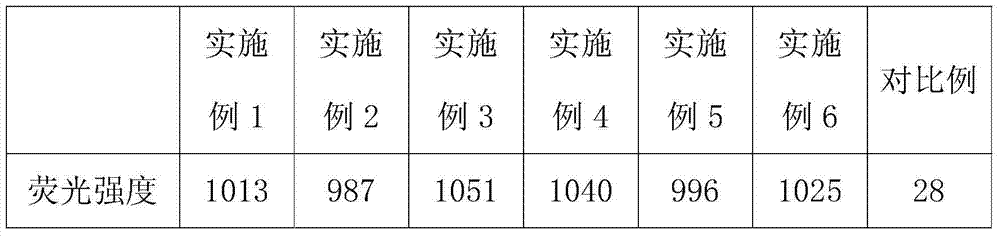

Examples

Embodiment 1

[0025] A preparation method of a novel fluorescent PVC wire and cable sheath material, the steps are as follows:

[0026] (1) cerium chloride is dissolved in ethanol to obtain a cerium chloride solution, and o-phenanthroline is dissolved in ethanol to obtain an o-phenanthroline solution, and p-toluic acid and ethanol are heated and stirred until completely dissolved, and the heating temperature is 60°C, use ammonia water to adjust the pH value to 9 to obtain p-toluic acid solution, heat and stir the cerium chloride solution and o-phenanthroline solution together for 20 minutes, then add p-toluic acid solution, the heating temperature is 60°C, continue After stirring for 1.5 hours, let it stand for 20 hours, filter and wash with ethanol, place it in a vacuum drying oven at 90°C and dry to obtain a white powder, wherein the molar ratio of cerium chloride, o-phenanthroline, and p-toluic acid The ratio is 2:5:3. Dissolve the white powder in dimethyl fumarate, add distilled water u...

Embodiment 2

[0031] A preparation method of a novel fluorescent PVC wire and cable sheath material, the steps are as follows:

[0032] (1) cerium chloride is dissolved in ethanol to obtain a cerium chloride solution, and o-phenanthroline is dissolved in ethanol to obtain an o-phenanthroline solution, and p-toluic acid and ethanol are heated and stirred until completely dissolved, and the heating temperature is 60°C, use ammonia water to adjust the pH value to 9 to obtain p-toluic acid solution, heat and stir the cerium chloride solution and o-phenanthroline solution together for 20 minutes, then add p-toluic acid solution, the heating temperature is 60°C, continue After stirring for 1.5 hours, let it stand for 20 hours, filter and wash with ethanol, place it in a vacuum drying oven at 90°C and dry to obtain a white powder, wherein the molar ratio of cerium chloride, o-phenanthroline, and p-toluic acid The ratio is 2:5:3. Dissolve the white powder in dimethyl fumarate, add distilled water u...

Embodiment 3

[0037] A preparation method of a novel fluorescent PVC wire and cable sheath material, the steps are as follows:

[0038] (1) cerium chloride is dissolved in ethanol to obtain a cerium chloride solution, and o-phenanthroline is dissolved in ethanol to obtain an o-phenanthroline solution, and p-toluic acid and ethanol are heated and stirred until completely dissolved, and the heating temperature is 60°C, use ammonia water to adjust the pH value to 9 to obtain p-toluic acid solution, heat and stir the cerium chloride solution and o-phenanthroline solution together for 20 minutes, then add p-toluic acid solution, the heating temperature is 60°C, continue After stirring for 1.5 hours, let it stand for 20 hours, filter and wash with ethanol, place it in a vacuum drying oven at 90°C and dry to obtain a white powder, wherein the molar ratio of cerium chloride, o-phenanthroline, and p-toluic acid The ratio is 2:5:3. Dissolve the white powder in dimethyl fumarate, add distilled water u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com