Preparation method of hexagonal boron nitride powder and three-dimensional boron nitride

A technology of hexagonal boron nitride and boron nitride, which is applied in the fields of chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low volume density and unfavorable macro-production, and achieve high density, large-scale preparation and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

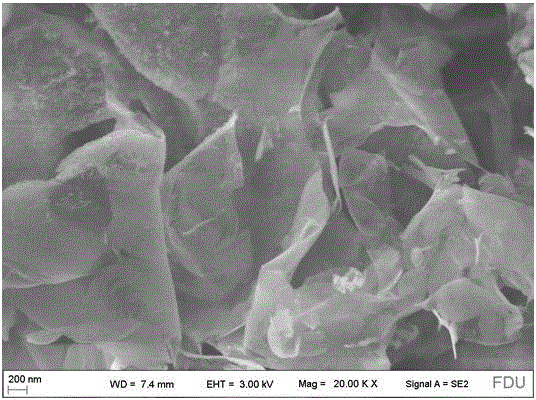

[0032] Embodiment 1, at first, the preparatory work before reaction: 0.5 gram borane ammonium complex (boron, nitrogen source), 0.5 gram nickel powder (catalyst) are packed in the same quartz tube, wherein, borane ammonia place quartz tube The front end is wrapped with a heating jacket, and the quartz tube where the nickel powder is located is placed in a tube furnace. Turn on the vacuum pump to evacuate the air pressure inside the quartz tube to 5×10 -3 Below Torr, a flow rate of 400 ml per minute of argon is introduced to flush the air pressure back to normal pressure, and the argon is continued to be introduced to exhaust the air (at this time until the end of the reaction, the gas outlet valve is opened to maintain the normal pressure environment), at 50 ℃ The temperature of the tube furnace was raised to 1000 degrees Celsius at a rate of 1 minute, and then the argon gas was turned off, and 200 milliliters of hydrogen gas per minute was introduced to reduce and anneal the ...

Embodiment 2

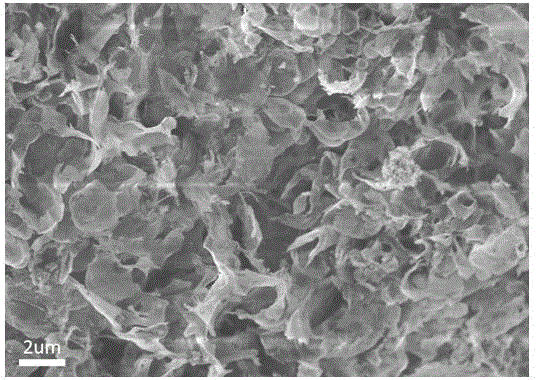

[0035] Embodiment 2, preparation method is basically the same as embodiment 1, and difference is: adopt copper powder as catalyst, the solution of post-etching catalyst adopts the hydrochloric acid mixed solution of 1 mole per liter of iron trichloride and 0.1 mole per liter, can Obtain hexagonal boron nitride powder.

[0036] 2. Preparation of three-dimensional boron nitride

Embodiment 3

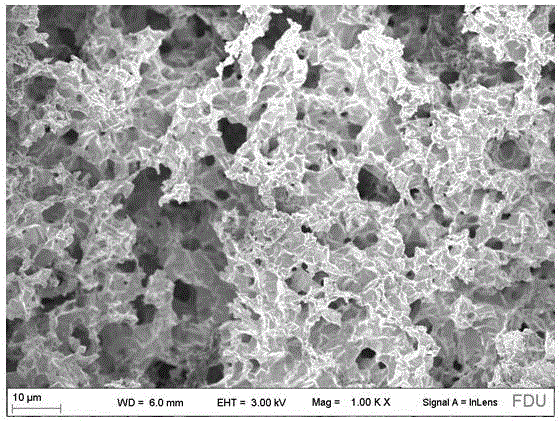

[0037] Embodiment 3, preparation method is basically the same as embodiment 1, also adopts nickel powder to make catalyst. The difference is in the sample treatment part after growth: before etching the nickel skeleton with 3 moles per liter of hydrochloric acid, the sample was first immersed in anisole solution of polymethyl methacrylate (4% by mass) for 10 After a few minutes remove to dry. After etching the catalyst, three-dimensional boron nitride (such as image 3 ), and then dissolve and remove polymethyl methacrylate with acetone to obtain three-dimensional boron nitride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com