Production method of functional protein feed rich in four essential amino-acids

An essential amino acid and protein feed technology, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, animal feed, etc., can solve the problems of increasing the cost of feeding, and it is difficult to increase the content of essential amino acids in fermented protein feeds, so as to reduce contamination and impurities. The probability of bacteria, shortening the solid-state fermentation time, and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

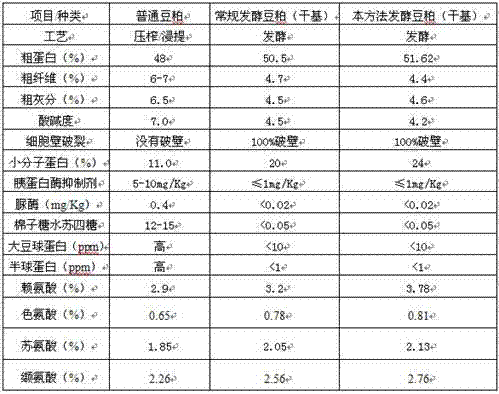

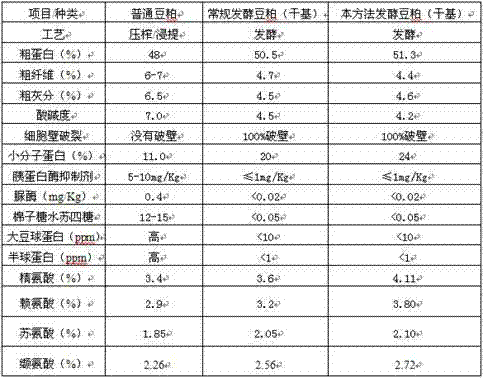

Image

Examples

Embodiment 1

[0028] The functional protein feed production method rich in four essential amino acids of lysine, arginine, threonine and valine of the present invention comprises the steps:

[0029] The first step, liquid fermentation

[0030] Make a suspension of four types of Corynebacterium glutamicum (numbered CICC 20906, CICC 20191, CICC 20903 and CICC 20887) on beef extract peptone with 200ml sterile saline, and mix them at a ratio of 1:1:1:1 Afterwards, it is inoculated into the liquid fermentation medium and cultivated (60% liquid filling capacity), and the medium consists of: glucose 120g / L, (NH 4 ) 2 SO 4 30g / L, corn steep liquor 20g / L, KH 2 PO 4 1.5g / L, MgSO 4 ·7H 2 O0.5 g / L, biotin 8×10 -5 g / L, CaCO 3 30 g / L; pH 7.0, sterilized at 0.12 MPa for 20 min; culture conditions: tank pressure 0.1 Mpa, stirring speed 230 r / min, ventilation rate 1:0.25, culture temperature 30°C, fermentation time 48 h; YPD Candida parapsilosis (number CICC 1257) on the culture medium was made...

Embodiment 2

[0042] The functional protein feed production method rich in four essential amino acids of arginine, threonine, valine and tryptophan of the present invention comprises the following steps:

[0043] The first step, liquid fermentation

[0044] The preparation method of the mixed bacteria solution of four kinds of Corynebacterium glutamicum (numbered CICC 20191, CICC 20903, CICC 20887 and CICC 20192) and Candida parapsilosis (numbered CICC 1257) is the same as that in Example 1;

[0045] Take the slanted seeds of Bacillus natto (number CICC23413) and inoculate them in a 500ml eggplant-shaped bottle filled with peptone beef extract medium, and use 200ml of sterile saline to make a suspension of Bacillus natto first-grade solid seeds, and inoculate Fermentation culture in 2m3 fermenter (seed tank culture medium filling volume 60%), medium composition: 2.0% soybean flour, 1.5% corn flour, 0.4% magnesium sulfate, 0.05% manganese sulfate, 1.0% sodium chloride; Conditions: tank pres...

Embodiment 3

[0056] The functional protein feed production method rich in four essential amino acids of lysine, threonine, valine and tryptophan of the present invention comprises the following steps:

[0057] The first step, liquid fermentation:

[0058] Four kinds of Corynebacterium glutamicum (numbered as CICC 20906, CICC 20903, CICC 20887 and CICC 20192) and Candida parapsilosis mixed fermentation method are the same as in Example 1; the production method of Lactobacillus plantarum fermentation mash is the same as in Example 1 Identical; Bacillus natto fermentation mash production method is identical with embodiment 2.

[0059] The second step is to prepare the fermented mash:

[0060] Mix the fermented liquid prepared in the first step with 40 parts of Corynebacterium glutamicum and Trichosporium viscosus mixed bacteria fermented liquid, 20 parts of Lactobacillus plantarum fermented liquid, and 20 parts of Bacillus natto fermented liquid, and mix them evenly to obtain fermented mash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com