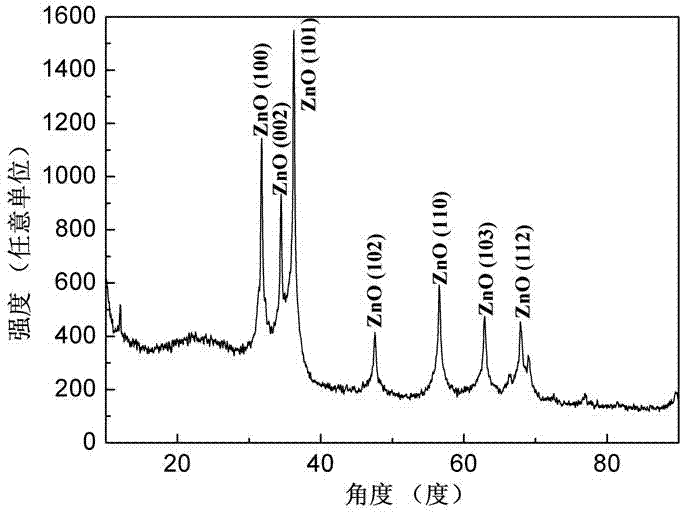

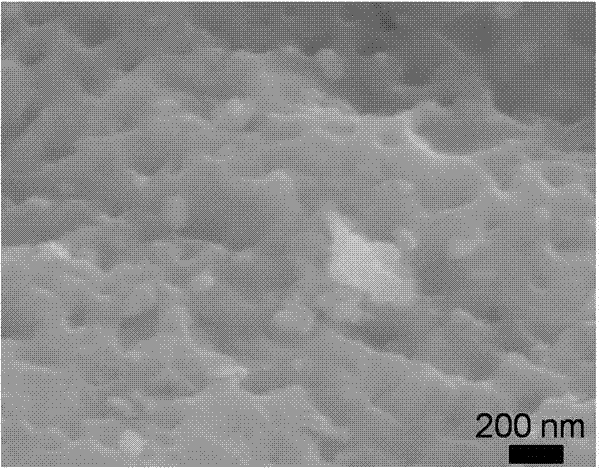

Carbon-coated iron-doped zinc oxide and rapid synthetic method thereof

A synthesis method, iron doping technology, applied in the field of carbon-coated iron-doped zinc oxide (ZnO:Fe) and its rapid synthesis, to achieve strong light absorption, high crystal quality, and enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 1.5 g of zinc nitrate, 0.4 g of ferric nitrate, 0.7 g of citric acid, and 0.1 g of ammonium nitrate, respectively, to prepare an aqueous solution, stir and dissolve until a transparent solution is obtained. The solution was heated to 80 °C, and the water was continuously evaporated to a viscous gel state. The gel was heated in an environment of 250 °C, and the gel self-propagatingly burned within a few minutes to obtain a black loose powder. The obtained powder was added into ethanol to wash and dried to obtain high-purity carbon-coated ZnO:Fe powder.

Embodiment 2

[0027] Weigh 1.5 g of zinc nitrate, 0.25 g of ferric chloride, 1 g of citric acid, and 0.2 g of ammonium nitrate, respectively, to prepare an aqueous solution, stir and dissolve until a transparent solution is obtained. The solution was heated to 100 °C, and the water was continuously evaporated to a viscous gel state. The gel was heated in an environment of 180 °C, and the gel self-propagatingly burned within a few minutes to obtain a black loose powder. The obtained powder was added into ethanol to wash and dried to obtain high-purity carbon-coated ZnO:Fe powder.

Embodiment 3

[0029] Weigh 0.7 g of zinc chloride, 0.1 g of ferric sulfate, 0.4 g of glycine and 0.4 g of ammonium nitrate, respectively, to prepare an aqueous solution, stir and dissolve to a transparent solution. The solution was heated to 50 °C, and the water was continuously evaporated to a viscous gel state. The gel was heated in an environment of 290 °C, and the gel self-propagatingly burned within a few minutes to obtain a black loose powder. The obtained powder was added into deionized water to wash and dried to obtain high-purity carbon-coated ZnO:Fe powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com