A kind of asphalt porous material and its preparation method and application

A technology of porous materials and asphalt, applied in the field of asphalt, can solve the problems of low specific surface area, poor safety performance and large average pore size of hard carbon materials, and achieve good gas adsorption and storage performance, good dye adsorption performance, and mild production conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

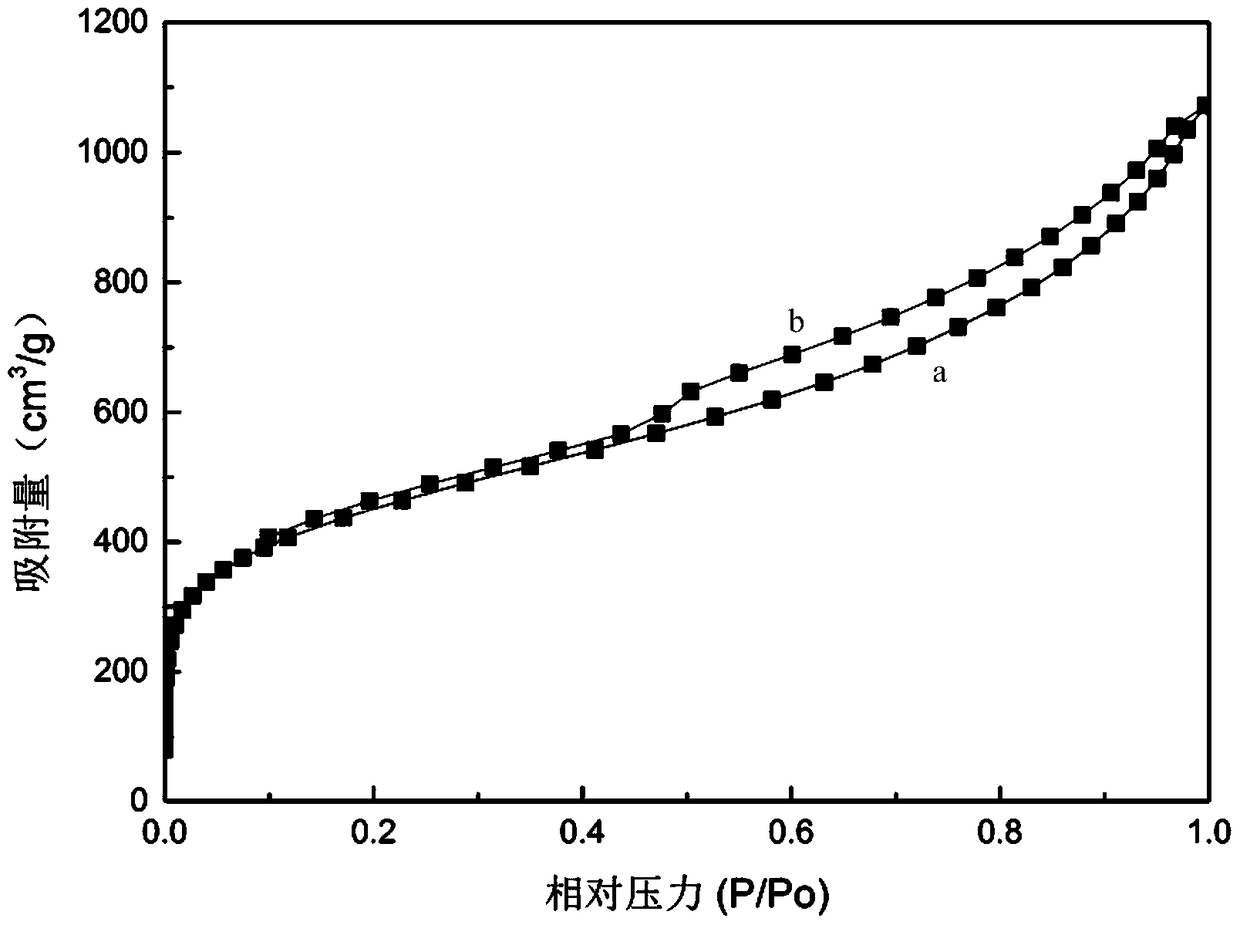

[0027] The preparation specific surface area is 700m 2 / g, the pore volume is 0.30m 3 / g hypercrosslinked asphalt porous material.

[0028] The present embodiment adopts following formula:

[0029] Petroleum asphalt: 100kg;

[0030] Dimethoxymethane: 49kg;

[0031] Anhydrous ferric chloride: 210kg;

[0032] Dichloroethane: 500L.

[0033] Prepare asphalt porous material with above-mentioned formula composition according to following method:

[0034] 1. Dissolve the weighed petroleum asphalt in 1,2-dichloroethane. After the dissolution is complete, add dimethoxymethane, dissolve, stir and mix evenly, then add ferric chloride, mix evenly.

[0035] 2. Add the mixed composition to 80°C at one time, and crosslink for 12 hours.

[0036] 3. Add the solid obtained in step 2 into methanol, wash away part of the ferric chloride, extract with methanol for 5 hours, then extract with dichloromethane for 5 hours, and dry at 80°C for 12 hours.

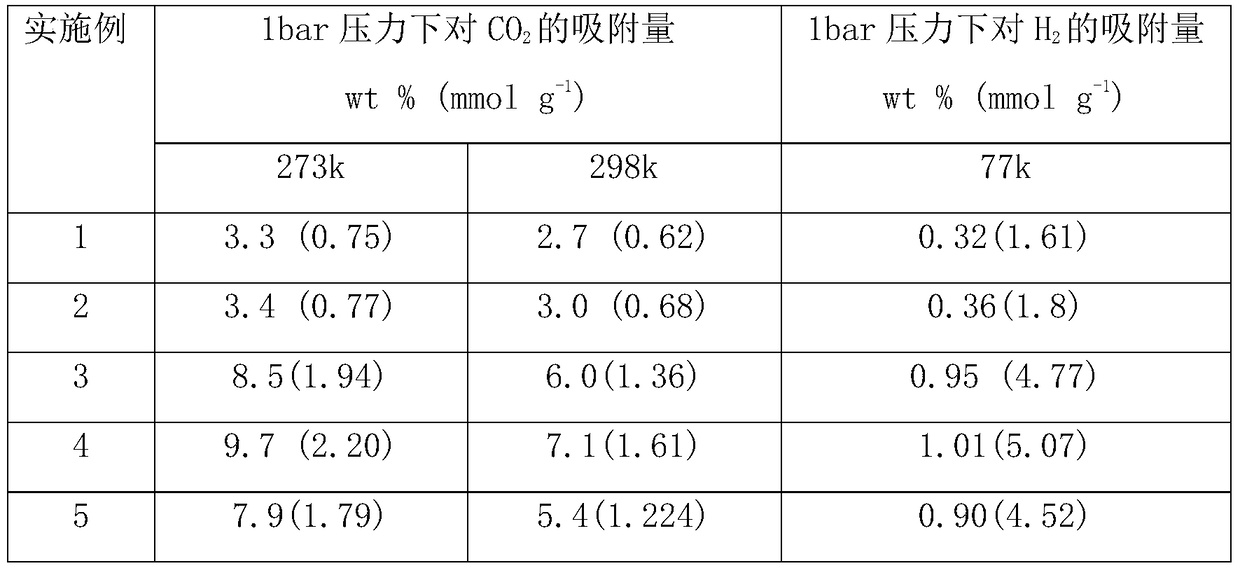

[0037] The asphalt porous material prep...

Embodiment 2

[0039] The preparation specific surface area is 760m 2 / g, the pore volume is 0.32m 3 / g hypercrosslinked asphalt porous material.

[0040] The present embodiment adopts following formula:

[0041] Petroleum asphalt: 100kg;

[0042] Dimethoxymethane: 82kg;

[0043] Anhydrous aluminum trichloride: 350kg;

[0044] Dichloroethane: 500L.

[0045] Prepare asphalt porous material with above-mentioned formula composition according to following method:

[0046] 1. Dissolve the weighed petroleum asphalt in 1,2-dichloroethane. After the dissolution is complete, add dimethoxymethane, dissolve, stir and mix evenly, then add ferric chloride, mix evenly.

[0047] 2. Add the mixed composition to 80°C at one time, and crosslink for 12 hours.

[0048] 3. Add the solid obtained in step 2 into methanol, wash away part of the ferric chloride, extract with methanol for 5 hours, then extract with dichloromethane for 5 hours, and dry at 80°C for 12 hours.

Embodiment 3

[0050] The preparation specific surface area is 1452m 2 / g, the pore volume is 0.60m 3 / g hypercrosslinked asphalt porous material.

[0051] The present embodiment adopts following formula:

[0052] Petroleum asphalt: 100kg;

[0053] Biphenyl dichlorobenzyl: 320kg;

[0054] Anhydrous ferric chloride: 420kg;

[0055] Dichloroethane: 500L.

[0056] Prepare asphalt porous material with above-mentioned formula composition according to following method:

[0057] 1. Dissolve the weighed petroleum asphalt in 1,2-dichloroethane. After the dissolution is complete, add dimethoxymethane, dissolve, stir and mix evenly, then add ferric chloride, mix evenly.

[0058] 2. Add the mixed composition to 80°C at one time, and crosslink for 12 hours.

[0059] 3. Add the solid obtained in step 2 into methanol, wash away part of the ferric chloride, extract with methanol for 5 hours, then extract with dichloromethane for 5 hours, and dry at 80°C for 12 hours.

[0060] The asphalt porous mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com