Method for preparing anatase nano-titanium dioxide by pulsed electromagnetic field

A nano-titanium dioxide, pulsed electromagnetic field technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of strict material and safety requirements, difficult separation of additives and powder, difficult particle size control, etc., to achieve equipment Small footprint, good dispersion, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

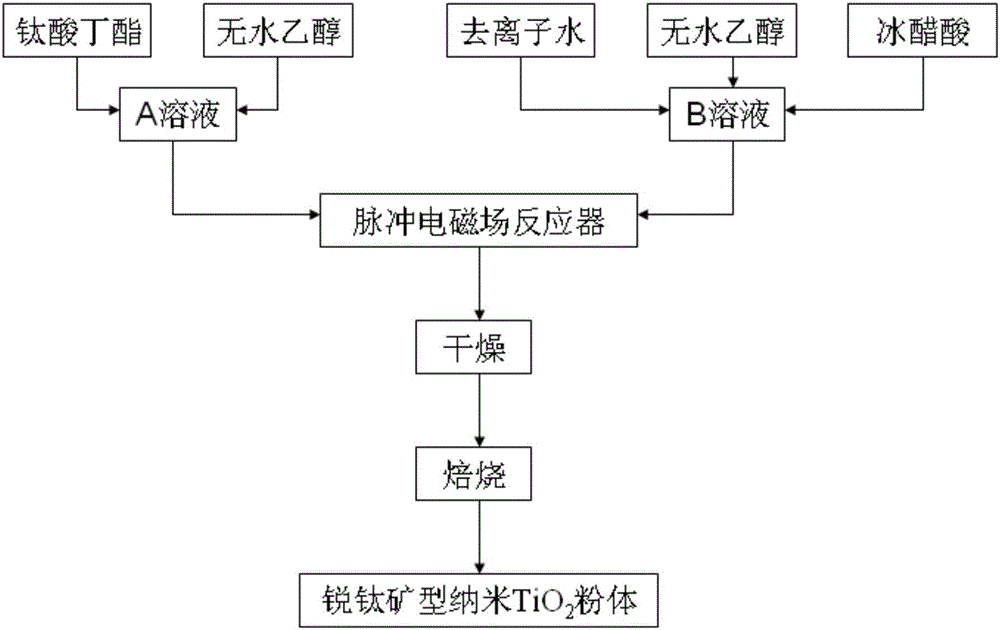

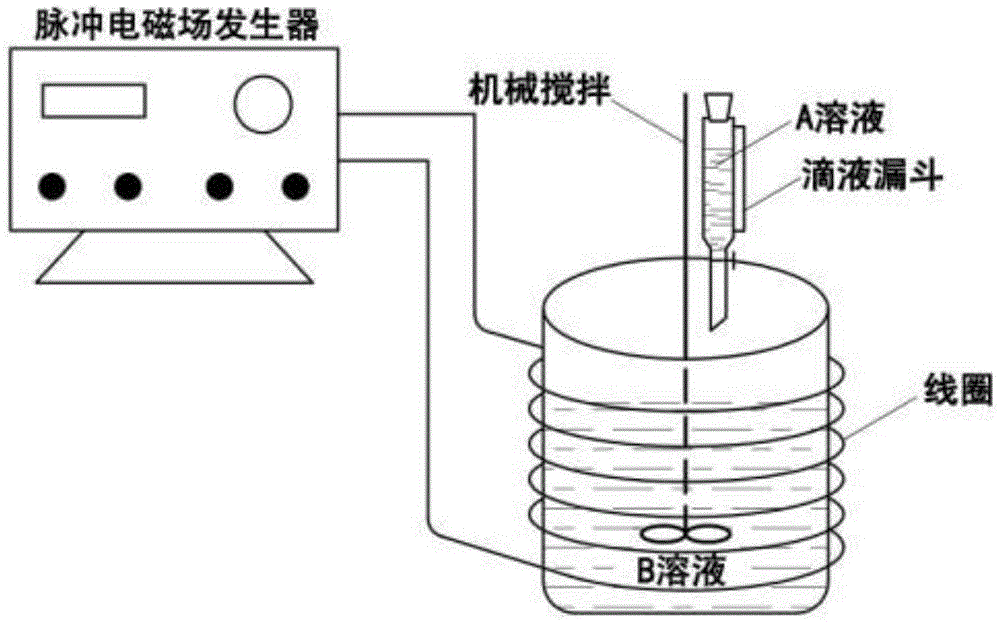

[0027] Such as figure 1 ,Such as figure 2 As shown, the preparation of anatase nano-TiO 2 The method is as follows:

[0028] 1.1. Take a certain amount of absolute ethanol and put it into a beaker as a solvent. According to the volume ratio of butyl titanate and absolute ethanol as 1:2, add butyl titanate to absolute ethanol. After the addition is complete, continue to stir for 10 minutes , until uniformly mixed to obtain a dilute butyl titanate solution (A solution);

[0029] 1.2. Mix water and absolute ethanol evenly according to the volume ratio of 1:4, and prepare ethanol aqueous solution;

[0030] 1.3. Add an appropriate amount of glacial acetic acid to the aqueous ethanol solution to adjust the pH of the aqueous ethanol solution to 3.5 (solution B);

[0031] 1.4. Take 35mL of the ethanol aqueous solution whose pH value was adjusted in step 1.3, stir it mechanically at a speed of 800r / min, and add 28mL of dilute butyl titanate solution to react at a rate of 10mL / min....

Embodiment 2

[0034] 1.1. Take a certain amount of absolute ethanol and put it into a beaker as a solvent. According to the volume ratio of butyl titanate and absolute ethanol as 1:3, add butyl titanate to absolute ethanol. After the addition is complete, continue to stir for 5 minutes , until uniformly mixed to obtain a dilute butyl titanate solution;

[0035] 1.2. Mix water and absolute ethanol evenly according to the volume ratio of 1:5, and prepare ethanol aqueous solution;

[0036] 1.3. Add an appropriate amount of glacial acetic acid to the aqueous ethanol solution to adjust the pH of the aqueous ethanol solution to 4;

[0037] 1.4. Take 30 mL of the ethanol aqueous solution whose pH value was adjusted in step 1.3, mechanically stir at a speed of 500 r / min, and drop 30 mL of dilute butyl titanate solution to react at a rate of 15 mL / min. The system is treated with a pulsed electromagnetic field. During the pulsed electromagnetic field treatment, the pulse time is 0.5min, the pulse vo...

Embodiment 3

[0040]1.1. Take a certain amount of absolute ethanol and put it into a beaker as a solvent. According to the volume ratio of butyl titanate and absolute ethanol as 1:1, add butyl titanate to absolute ethanol. After the dropwise addition, continue to stir for 5 minutes , until uniformly mixed to obtain a dilute butyl titanate solution;

[0041] 1.2. Mix water and absolute ethanol evenly according to the volume ratio of 1:3, and prepare ethanol aqueous solution;

[0042] 1.3. Add an appropriate amount of glacial acetic acid to the aqueous ethanol solution to adjust the pH of the aqueous ethanol solution to 3;

[0043] 1.4. Take 30mL of the ethanol aqueous solution whose pH value was adjusted in step 1.3, stir it mechanically at a speed of 1000r / min, and add 20mL of dilute butyl titanate solution to react at a rate of 5mL / min. The system is treated with a pulsed electromagnetic field. During the pulsed electromagnetic field treatment, the pulse time is 5min, the pulse voltage is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com