Nanorods or nanowires formed by carbon nanotubes filled with metal sulfide in inner cavities, and preparation method thereof

A metal sulfide, carbon nanotube technology, applied in the preparation of sulfide/polysulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve unfavorable carbon nanotubes, carbon nanotubes Truncation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned carbon nanotube lumen filled with metal sulfide nanorods or nanowires according to the present invention comprises the steps of:

[0035] Step 1: Select a carbon nanotube epoxy porous membrane with openings at both ends, and put the carbon nanotube epoxy porous membrane into a diffusion device to fix it.

[0036] In one embodiment, the above step 1 is specifically performed as follows: select a carbon nanotube epoxy porous membrane with openings at both ends, put the carbon nanotube epoxy porous membrane into a diffusion device and fix it, and the carbon nanotube epoxy porous membrane The preparation method of porous film comprises:

[0037](1) Preparation of carbon nanotube arrays: put silicon wafers evaporated with aluminum or aluminum oxide into a tube furnace, and grow carbon nanotube arrays by chemical vapor deposition. The chemical vapor deposition methods include:

Embodiment 1

[0051] In the electron beam evaporation equipment Ei-5z, 10nm Al and 1nm Fe were evaporated successively at the speed of 0.3nm / s and 0.1nm / s to the polished surface of a 4inch diameter single crystal silicon wafer. Place the silicon chip on which the catalyst is vapor-deposited in the middle of a quartz tube with an inner diameter of 1 inch. First pass 300 sccm of argon gas for 10 minutes to remove the air in the quartz tube. After reducing the argon flow rate to 100 and feeding 40 sccm of hydrogen, the temperature was raised from room temperature to 770° C. within 13. After the temperature was stabilized, 30 sccm of ethylene was introduced and kept for 10. When complete, stop ethylene flow and begin cooling. When the temperature drops below 700°C, the hydrogen flow is stopped. After the temperature continued to drop to room temperature, the prepared carbon nanotube array was taken out and the argon gas was stopped.

[0052] The carbon nanotube array is transferred to a pe...

Embodiment 2

[0056] The operation method is the same as Example 1. When preparing epoxy resin, the masses of each component are: SPI-PON 812: 2.7g NMA: 0.7g DDSA: 1.7g DMP-30: 0.07g. After the embedding is completed, it is sliced, and the slice thickness of the slicer is changed to 12 microns, and the speed is reduced to 50 rpm, so as to adapt to the hardness of the epoxy resin of this kind of ratio. Replace the deionized water on one side of the diffusion device with exhausted 0.1M sodium hydrosulfide ethanol solution, and replace the ultrapure water in the opposite diffusion cell with 0.1M copper acetate ethanol solution for 72 hours of diffusion. Other conditions remain unchanged, and the obtained carbon nanotubes are filled with metal copper sulfide nanorods.

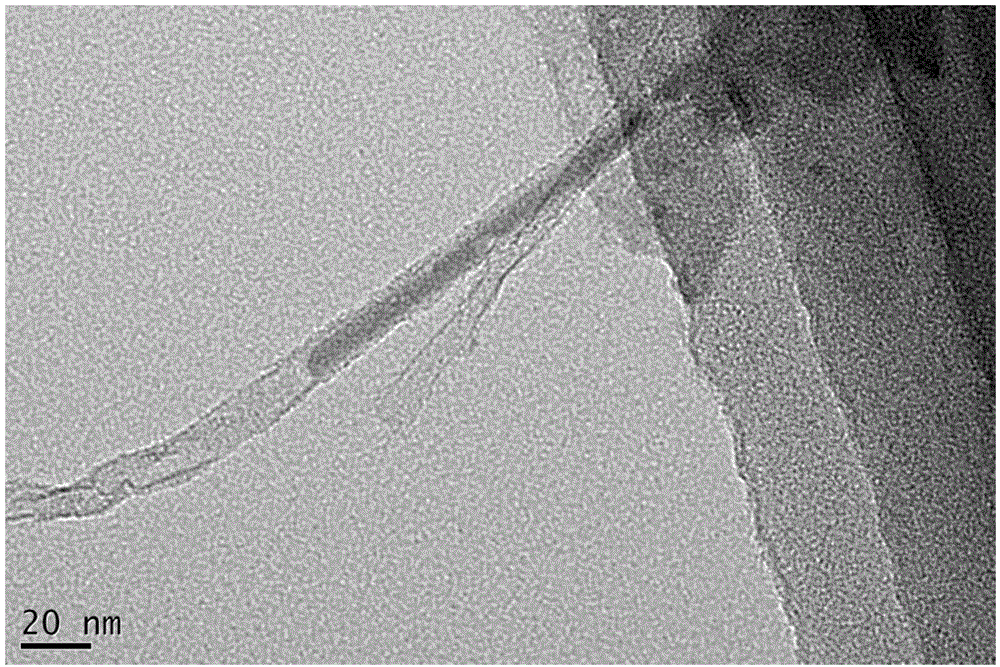

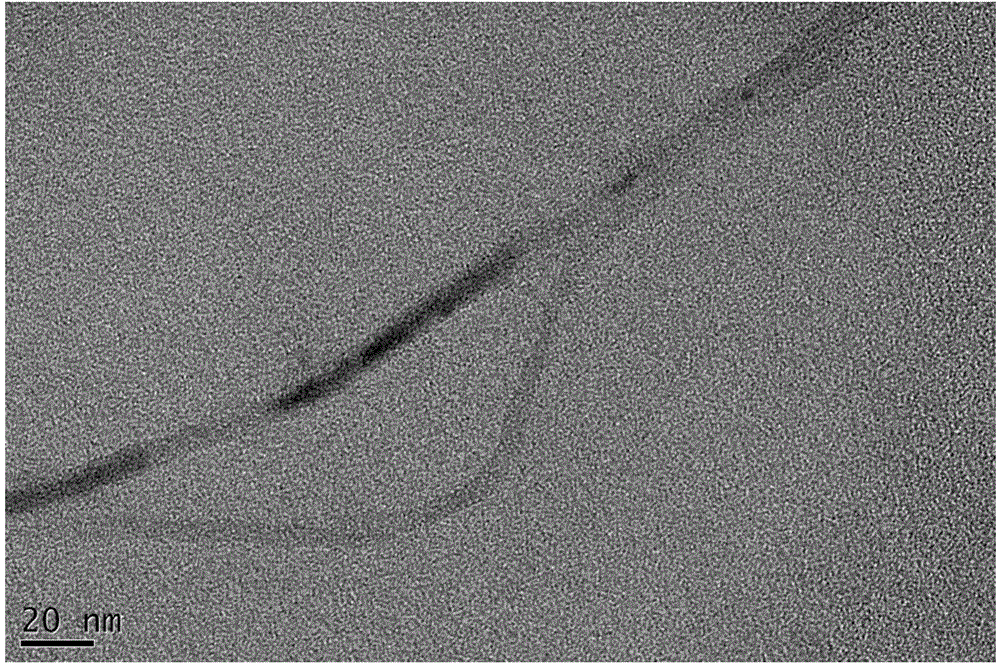

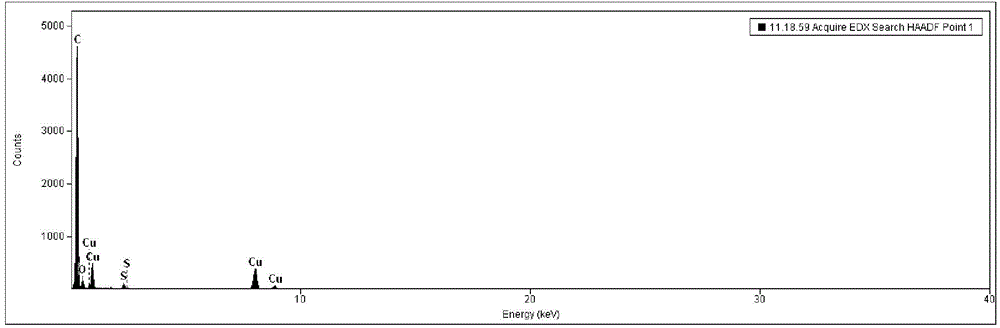

[0057] see figure 2 and image 3 , figure 2 It is the nanorod or nanowire of a kind of carbon nanotube lumen filling metal sulfide described in the present invention and preparation method thereof in the TEM picture of copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com