High-performance electric-conducting rubber material for aerospace, and preparation method and application thereof

A technology of aerospace and conductive rubber, applied in the field of modified rubber, can solve the problems that conductive materials cannot be applied, achieve excellent electrical and thermal conductivity, improve high temperature resistance, and improve poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

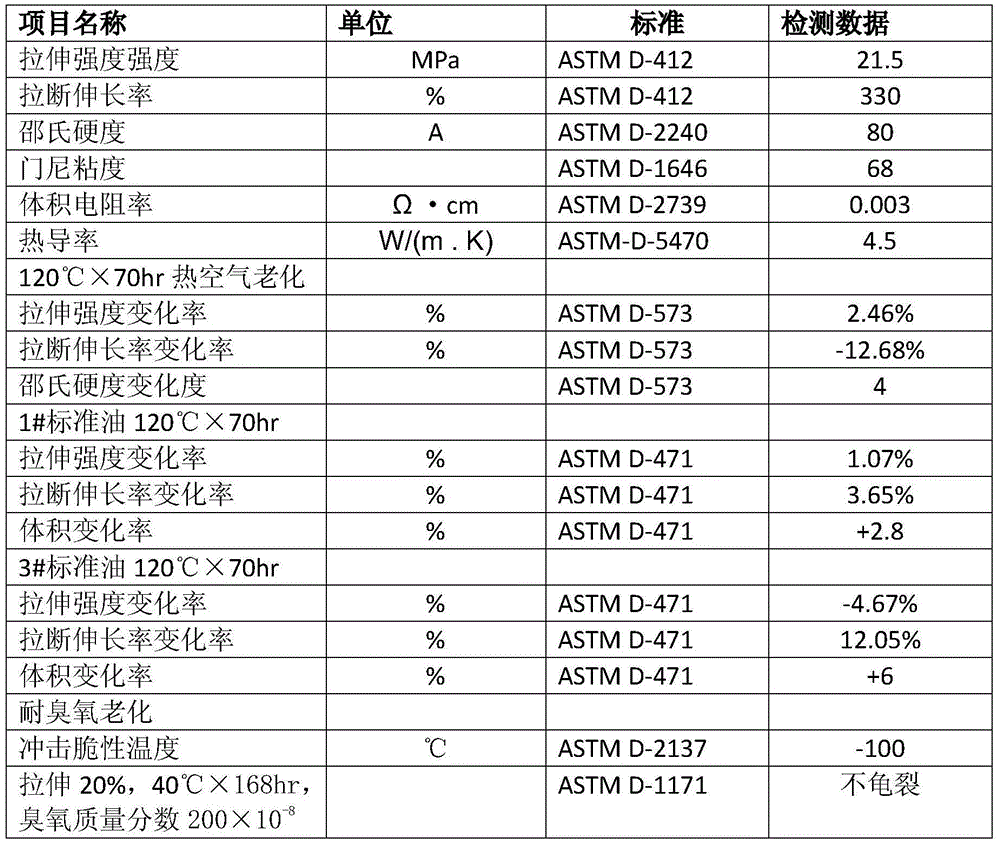

Embodiment 1

[0044] 1. Dissolve 20.3g of nickel nitrate and 17.9g of magnesium nitrate in 100ml of absolute ethanol to prepare a mixed catalyst precursor solution, and prepare a 1:1 mixed solution of 0.7mol / L of nickel nitrate and magnesium nitrate. Apply the prepared precursor solution evenly on the copper substrate and let it dry naturally;

[0045]2. Put the tin wire under the substrate after being wound, and put it on the deposition table in the cavity of the DC plasma chemical vapor deposition equipment. Close the vacuum chamber and turn on the vacuum pump to evacuate. When the pump pressure is less than 0.1 Pa, argon and hydrogen are introduced into the vacuum chamber. The flows of argon and hydrogen are 4L / min and 10L / min respectively, start the DC arc, adjust the arc current to 120A, adjust the exhaust valve and the vacuum chamber regulating valve to stabilize the pressure in the vacuum chamber at 3000Pa, and react for 8min to obtain Ni / MgO catalyst;

[0046] 3. Under the condit...

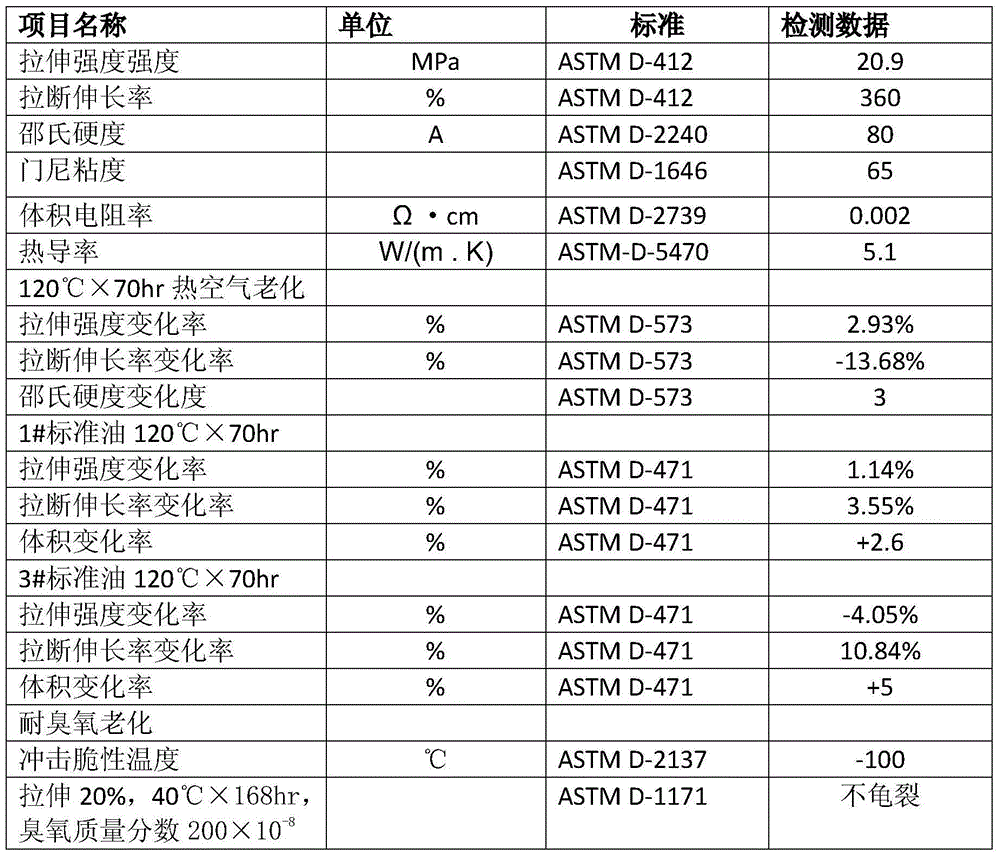

Embodiment 2

[0058] 1. The preparation and surface treatment of modified carbon nanotubes, graphene and aluminum nitride are the same as steps 1 to 6 in Example 1.

[0059] 2. First, add 150g of hydrogenated nitrile rubber, 50g of fluororubber 246, 50g of perfluoroether rubber, 10g of magnesium hydroxide and 5g of magnesium oxide into the internal mixer for mastication, and add the prepared modified rubber when the temperature rises to 50°C. 25g of permanent carbon nanotubes, 25g of modified graphene, 20g of surface-treated aluminum nitride and 30g of DOP for banburying, the banburying time is 2 minutes, and the temperature of the banbury mixer is 65°C; then add 30g of carbon black N330 and 30g of carbon black in sequence N550, 10g white carbon black, 20g calcium carbonate, 10g talcum powder, 40g kaolin, 10g coumarone resin and 10g polybutadiene resin, add 15g aromatic oil and 15g chlorinated paraffin during the period, continue banburying for 6min, internal mixer The temperature is 85°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com