Gallium nitride heterojunction MIS grid-control power diode and manufacturing method thereof

A technology of power diodes and heterojunctions, applied in the direction of diodes, electrical components, circuits, etc., can solve problems such as reverse leakage and unsatisfactory withstand voltage, increase forward working loss of devices, low forward turn-on voltage, etc., and achieve high The effects of reverse withstand voltage, high conduction current, and low forward turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

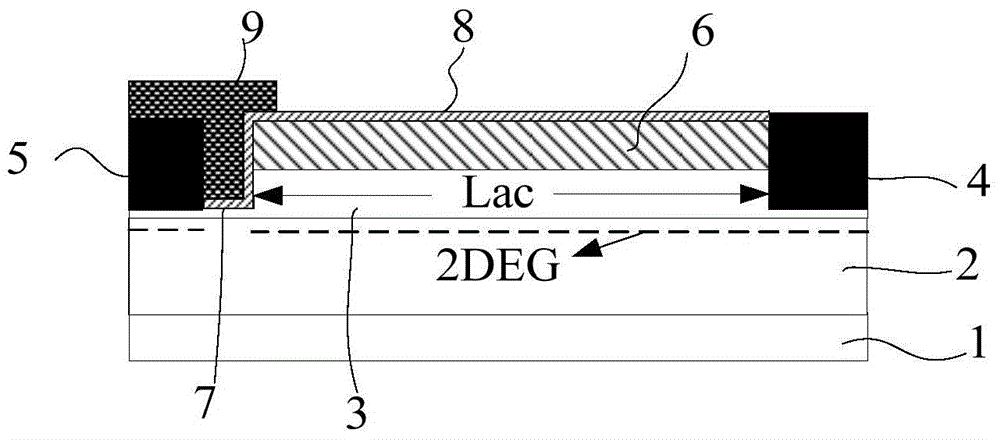

[0040] Figure 2-Figure 9 It is a schematic diagram of the manufacturing process steps of a gallium nitride heterojunction MIS power diode according to the present invention, and the process flow is as follows:

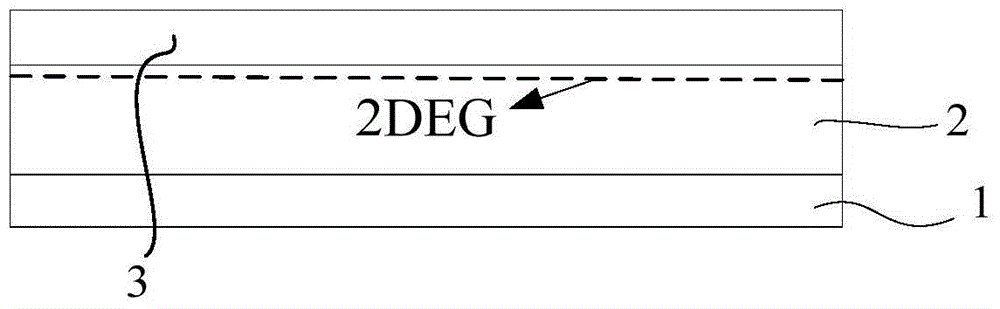

[0041] (1) Using metal-organic chemical vapor deposition or molecular beam epitaxy, a GaN layer 2 and a barrier layer AlXN layer 3 are sequentially grown on the substrate 1, such as figure 2 shown;

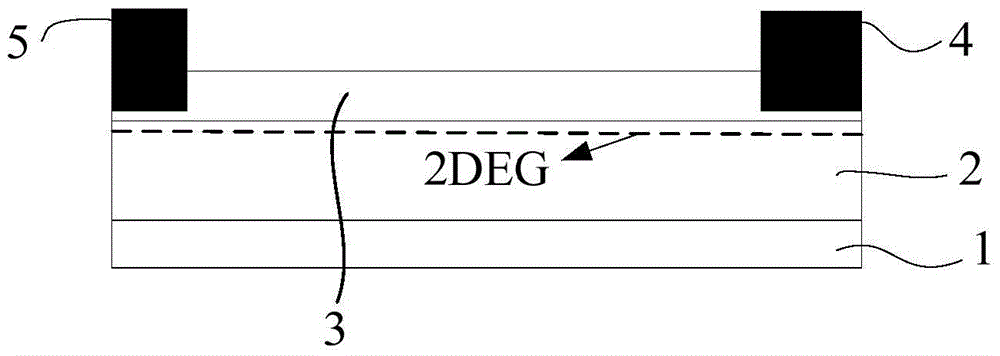

[0042] (2) Using photolithography technology, evaporate (or sputter) ohmic metal, and perform rapid thermal annealing to form the first ohmic contact metal 4 and the second ohmic contact metal 5, such as image 3 shown;

[0043] (3) Use ion implantation technology or dry etching mesa technology to form device-to-device isolation;

[0044] (4) Plasma-enhanced chemical vapor deposition is used to uniformly grow a passivation layer on the heterojunction barrier layer, such as Figure 4 shown. Using photolithography technology, the pattern of the groove area is photo-et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com