Bacterial cellulose porous foamed material and preparation method thereof

A technology of porous foam material and bacterial cellulose, which is applied in medical science, prosthesis, etc., can solve the problems of long time-consuming, environmental pollution, mechanical and physical properties of bacterial cellulose membrane, etc., and achieves short duration and high reaction efficiency. , The effect of simple and easy operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

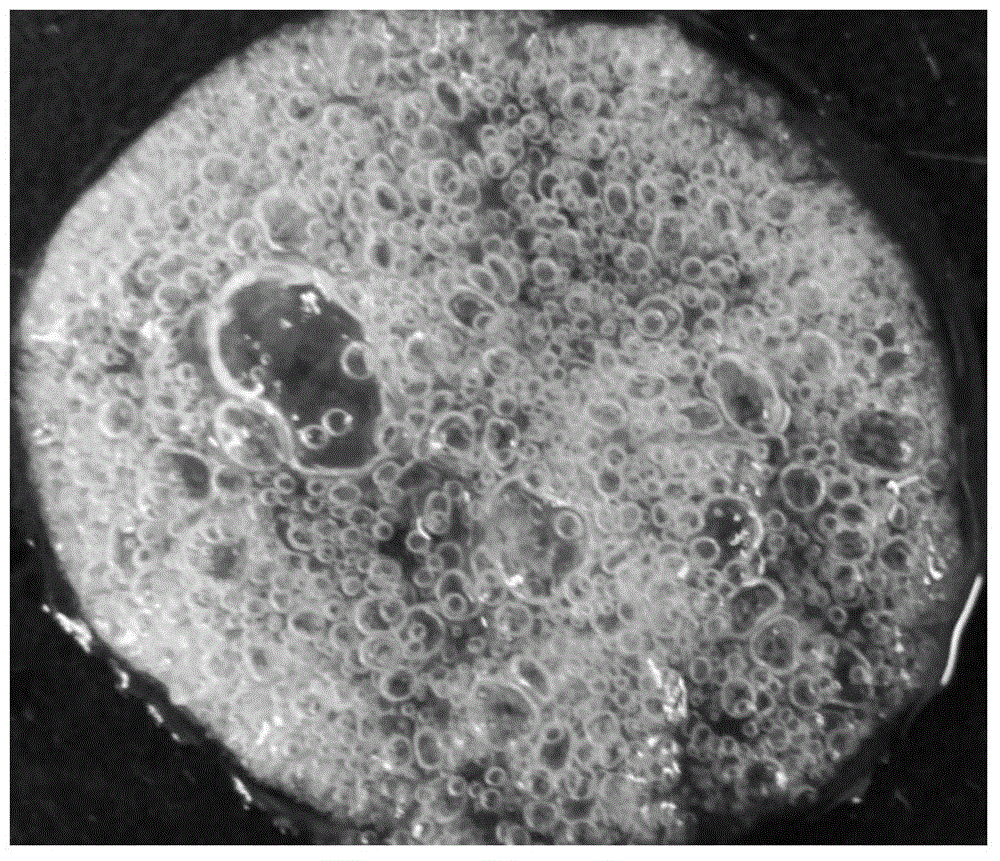

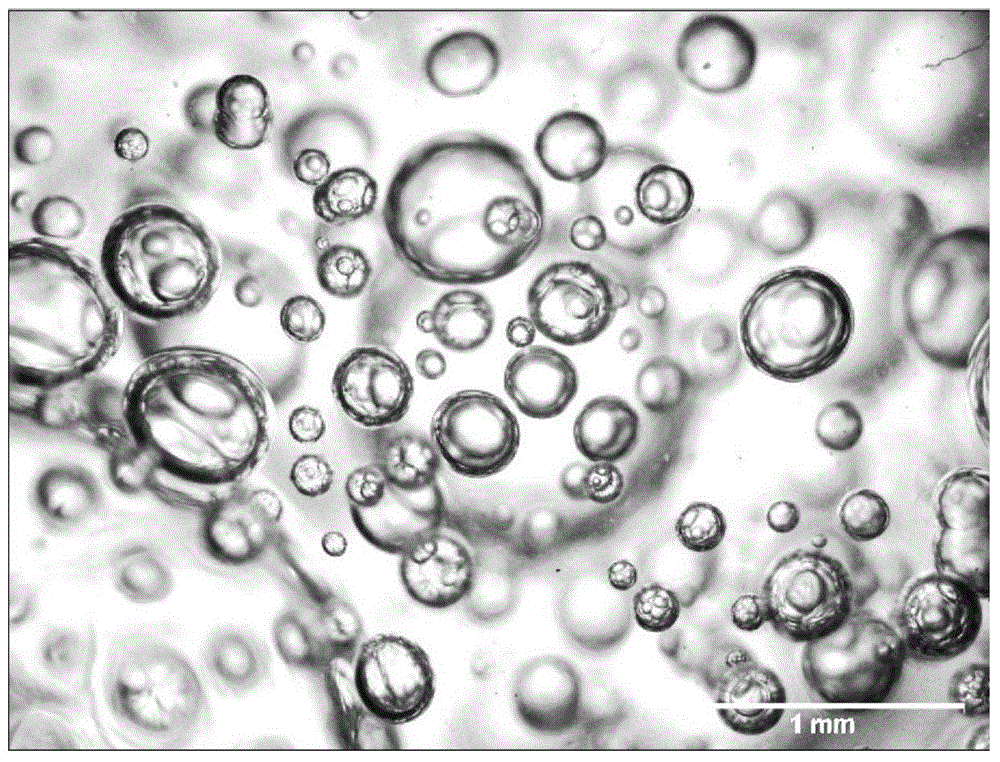

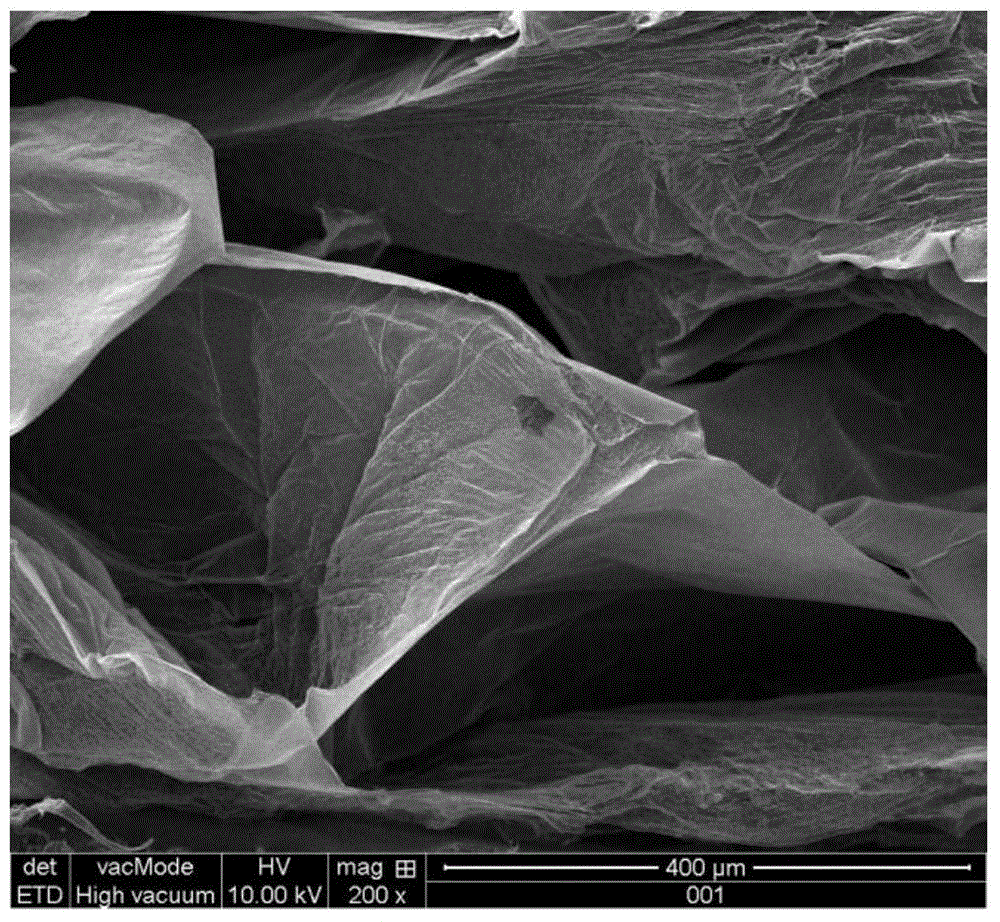

[0042] Acetobacter xylinum was used as the starting strain, and a milky white bacterial cellulose hydrogel film was prepared through fermentation. The bacterial cellulose membrane was treated with 0.5M sodium hydroxide solution at 80° C. for 2 hours, and the bacterial cellulose hydrogel membrane was treated continuously for 3 times to obtain a milky white translucent sheet-like jelly. The bacterial cellulose hydrogel film produced by Acetobacter xylinum was immersed in 10% (w / v) hydrogen peroxide solution for more than 24 hours, and sodium chlorite (the quality of sodium chlorite and hydrogen peroxide) was added in the reaction system The ratio is 4:1), shaking in the environment of 50 ℃ for more than 1 hour, then take out the sample and wash it repeatedly in water, the obtained sample is shown in figure 1 , the optical microscope observation picture see figure 2 . It can be seen with the naked eye that a large number of pores have been generated inside the bacterial cellu...

Embodiment 2

[0044] Microorganisms such as Acetobacter xylinum or Kombucha are used as production strains to obtain bacterial cellulose hydrogel membranes through fermentation. The bacterial cellulose membrane was treated with 0.5M sodium hydroxide solution at 80° C. for 2 hours, and the bacterial cellulose hydrogel membrane was treated continuously for 3 times to obtain a milky white translucent sheet-like jelly. The bacterial cellulose hydrogel membrane was immersed in 20% (w / v) hydrogen peroxide solution for 24 hours, and sodium chlorite was added to the reaction system (the mass ratio of sodium chlorite to hydrogen peroxide was 1:1, 2:1, 3:1, 4:1), shake in the environment of 50 ℃ for more than 1 hour, then take out the sample and wash it repeatedly in water. Figure 4 . Depend on Figure 4 Visible, along with the raising of the mass ratio of oxidant sodium chlorite and hydrogen peroxide, the stomatal aperture inside bacterial cellulose becomes smaller and quantity increases, and thr...

Embodiment 3

[0046] The bacterial cellulose hydrogel film prepared by microbial fermentation was treated with 0.5M sodium hydroxide solution at 80°C for 2 hours, and the bacterial cellulose hydrogel film was treated continuously for 3 times to obtain a milky white translucent flake gel body. The bacterial cellulose hydrogel membrane was immersed in a 30% (w / v) hydrogen peroxide solution to balance for more than 24 hours, and then the H 2 o 2 :NaClO 2 According to the following proportions (A) 5ml: 2.5g, (B) 5ml: 5g, (C) 5ml: 7.5g, (D) 5ml: 10g, add sodium chlorite solid to the reaction system and react at a temperature of 50°C 20min, the sample after the reaction is observed under an optical microscope after washing with water, and the results are shown in Image 6 . Image 6 It is shown that with the increase of the amount of sodium chlorite added, the pores in the range of 50-250 μm have reached more than 80% of all pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com