A kind of production method of granular anhydrous manganese chloride

An anhydrous manganese chloride, production method technology, applied in manganese halide and other directions, can solve the problems of high drying temperature, easy secondary pulverization and moisture absorption, material stagnation, etc., to reduce the drying residence time and improve the anti-absorption Moisture, avoid the effect of package scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

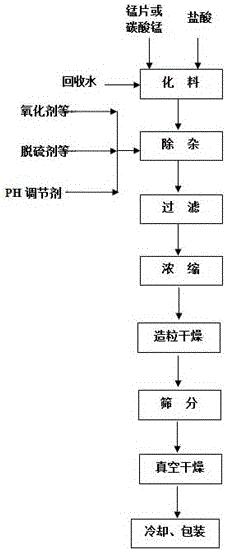

Image

Examples

Embodiment 1

[0033] Example 1 : A production method of granular anhydrous manganese chloride, comprising the steps of:

[0034]1) Chemical material: react manganese carbonate and hydrochloric acid at a molar ratio of 1:1.96 to obtain a concentration of 38 o The manganese chloride solution of Bé; The pH value of the control chemical end point is 6.5;

[0035] 2) Impurity removal: During the stirring process, slowly add hydrogen peroxide with a concentration of 27.5% and barium chloride aqueous solution with a concentration of 20% to the above chemical solution, and control the reaction temperature at 60°C; stir for 3.0 hours, and then add a pH regulator To adjust the pH value of the manganese chloride solution, when the pH value of the manganese chloride solution was stable at 6.0, filter to obtain the manganese chloride impurity removal solution.

[0036] 3) Filtration: filter to remove insoluble matter, obtain a refined manganese chloride solution after fine filtration, and adjust th...

Embodiment 2

[0043] Example 2 : A production method of granular anhydrous manganese chloride, comprising the steps of:

[0044] 1) Chemical material: react manganese carbonate and hydrochloric acid at a molar ratio of 1:1.98 to obtain a concentration of 36 o Bé's manganese chloride solution, the pH value of the control chemical end point is 5.6.

[0045] 2) Impurity removal: During the stirring process, slowly add 15% hydrogen peroxide and freshly synthesized barium carbonate slurry (containing about 26% barium carbonate) to the above chemical solution, and control the reaction temperature at 75°C. After 2.5 hours, add a pH regulator to adjust the pH value of the manganese chloride solution, and when the pH value of the manganese chloride solution is stable at 6.5, filter to obtain a manganese chloride impurity-removing solution.

[0046] 3) Filtration: filter to remove insoluble matter, obtain a refined manganese chloride solution after fine filtration, and adjust the pH of the solut...

Embodiment 3

[0053] Example 3 : A production method of granular anhydrous manganese chloride, comprising the steps of:

[0054] 1) Chemical material: react manganese flakes with hydrochloric acid at a molar ratio of 1:1.99 to obtain a concentration of 36 o For the manganese chloride solution of Bé, the pH value at the end point of the chemical material is controlled to be 5.0.

[0055] 2) Impurity removal: During the stirring process, slowly add 10% hydrogen peroxide and freshly synthesized barium carbonate slurry (containing about 3% barium carbonate) to the above chemical solution, and control the reaction temperature at 86°C; stir the reaction After 2 hours and 40 minutes, add a pH regulator to adjust the pH value of the manganese chloride solution. When the pH value of the manganese chloride solution is stable at 5.5, filter to obtain the manganese chloride impurity removal solution.

[0056] 3) Filtration: filter to remove insoluble matter, obtain a refined manganese chloride sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com