Quantum dot sensitized solar cell and preparation method thereof

A technology for quantum dot sensitization and solar cells, which is applied in the field of quantum dot sensitization solar cells and their preparation, can solve the problems of difficulty in precise control of the thickness of the passivation layer, inability to suppress interfacial recombination, and incomplete surface coverage of thin films, etc. Achieve the effect of improving battery efficiency, inhibiting recombination and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

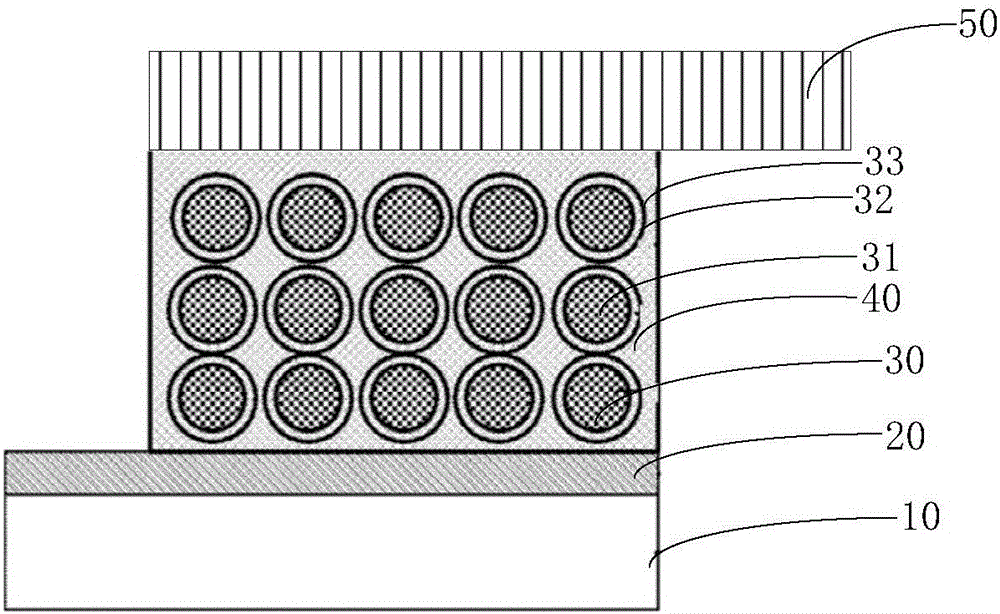

Image

Examples

Embodiment 1

[0034] 1) First screen print a layer of TiO on the FTO glass 2 The slurry is heated at 450° C. for 30 minutes to obtain a nanocrystalline porous layer with a thickness of 3-10 μm, which forms a photoanode.

[0035] 2) Add 40 microliters of 50mM CdSe x Te 1-x The QDs solution is dropped on the surface of the nanocrystalline porous layer, and quantum dots are deposited on the surface of the nanocrystalline porous layer film by diffusion adsorption to form a quantum dot film layer.

[0036] 3) Using atomic layer deposition technology to form a surface modification layer on the quantum dot film:

[0037] Take 10g Al(OC 2 h 5 ) 3 Precursor, which is dispersed in the organic solvent ethanol, and then will contain Al(OC 2 h 5 ) 3 The ethanol solution and water vapor are alternately sent into the reaction chamber in the form of gas pulses, and deposited on the quantum dot layer on the surface of the nanocrystalline particles for chemical adsorption and reaction, and high-puri...

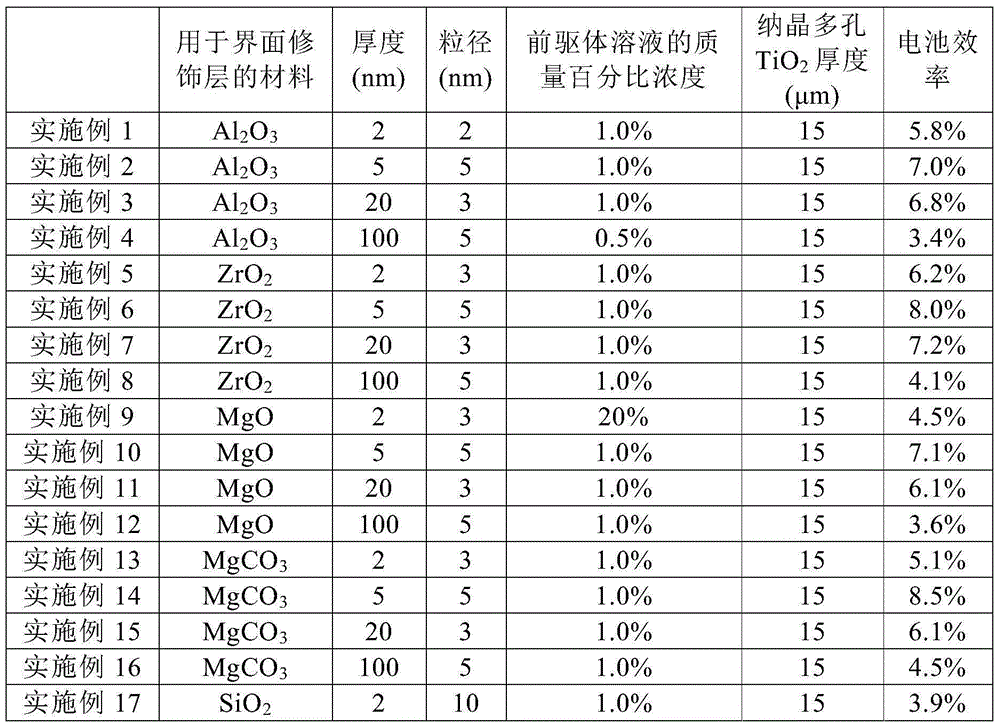

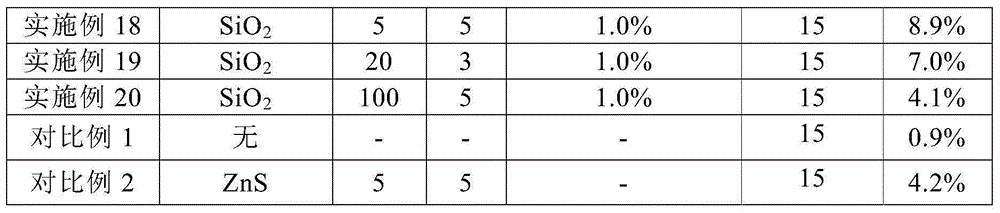

Embodiment 2-20

[0041] The preparation method is the same as that of Example 1, except for the material, thickness, and particle size used for the surface modification layer, see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com