Preparation method and application of activated-carbon-fiber-supported ordered mesoporous carbon-graphene composite material

A technology of activated carbon fibers and composite materials, which is applied in the field of preparation of novel activated carbon fibers loaded ordered mesoporous carbon-graphene composite materials, can solve the problems of high application potential and low current efficiency, achieve low cost, simple preparation method, The effect of excellent catalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

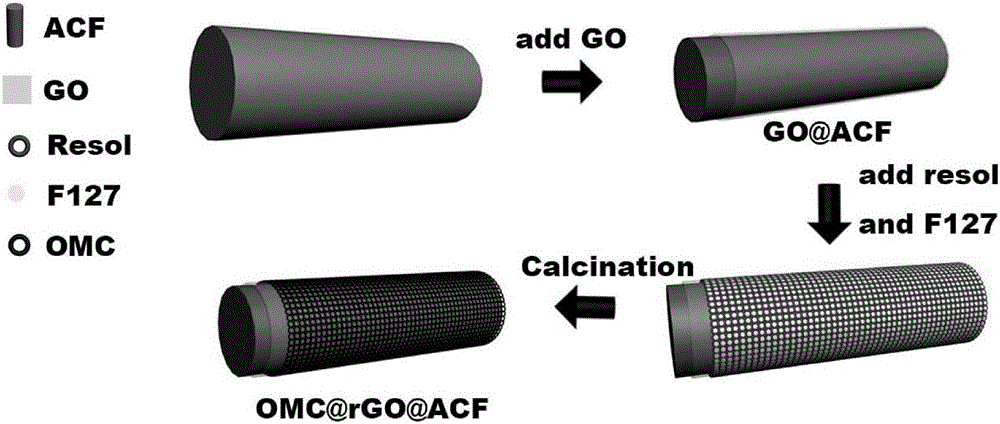

[0045] A new type of activated carbon fiber loaded ordered mesoporous carbon-graphene (OMCrGOACF) layered composite material, the preparation steps are as follows:

[0046] (1) Preparation of phenolic resin carbon source:

[0047] Weigh 12.2g of phenol into a round bottom flask, stir to dissolve in a water bath at 43℃, add 2.60g of 20wt% NaOH aqueous solution, stir for 10min, slowly drop 21g of 37wt% formaldehyde solution at 50℃, stirring at 79℃ After reacting for 1 h, the reaction product was cooled to room temperature, and then 0.6 mol / L HCl was dropped into the reaction product to adjust the pH value of the reaction product to 6.9, and water was removed by rotary evaporation at 50° C. The obtained yellow oily product was diluted with absolute ethanol to 20 wt% for use.

[0048] (2) Preparation of graphene oxide (GO):

[0049] Take 20.0mL98wt%H respectively 2 SO 4 , 5.0gP 2 O 5 And 5.0gK 2 S 2 O 8 In a round bottom flask, the solution was heated to 80°C after mixing uniformly, 10g g...

Embodiment 2

[0060] Example 2: Hydrogen peroxide test of OMCrGOACF-x

[0061] 1. Preparation of the electrode

[0062] The OMCrGOACF-x (size 3cm×3cm) prepared in Example 1 was wrapped on a 3cm×3cm pure titanium sheet as a cathode, and a platinum electrode was used as an anode. The platinum electrode (Shanghai Russell Technology Co., Ltd., Model 213) is combined with the OMCrGOACF-x cathode, and the side covered with OMCrGOACF-x is opposite to the platinum electrode, and the electrode is used in the E-Fenton system.

[0063] 2. Preparation of titanium reagent

[0064] Take 68mL98wt% concentrated sulfuric acid and pour it into 100mL distilled water. After the solution is cooled to room temperature, add 8.85g potassium titanium oxalate·dihydrate [K 2 TiO(C 2 O 4 ) 2 ·2H 2 O], finally transferred to a 250mL volumetric flask, add distilled water to a constant volume and shake well before use.

[0065] 3. Electric hydrogen peroxide experiment:

[0066] The experiment process uses a three-electrode system....

Embodiment 3

[0067] Example 3: Impedance measurement of OMCrGOACF-x prepared in Example 1

[0068] A three-electrode system was used in the impedance measurement experiment. The OMCrGOACF-x composite material is the working electrode, the platinum electrode is the auxiliary electrode, and the calomel electrode is the reference electrode. 100mL solution with pH=3.0 contains: 0.1mol / LNa 2 SO 4 And 1×10 - 3 mol / LFe 2+ . Adjust the electrochemical workstation, the AC impedance test conditions are: the initial voltage is the open circuit voltage, and the measurement frequency range is 10 5 ~1Hz, and finally use Zview to process the data to get the impedance.

[0069] Example 4: The OMCrGOACF-x prepared in Example 1 is applied to the electro-Fenton system as an oxygen diffusion cathode to degrade the endocrine disruptor dimethyl phthalate (DMP) test

[0070] During the E-Fenton degradation experiment of DMP, DMP wastewater was simulated by DMP aqueous solution. The degradation process uses a three-e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com