Method and device for performing electrochemical strengthening liquid phase catalysis and low-temperature splitting decomposition on biomass

A low-temperature cracking and strengthening liquid technology, applied in chemical instruments and methods, chemical/physical processes, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of difficult catalysts, simple environment, low utilization rate of waste heat, etc. The effect of accelerating the cracking rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The method for electrochemically strengthening liquid-phase catalytic low-temperature pyrolysis of biomass, the specific content is as follows:

[0019] 1. Mix 1.5kg of corn stalks with 3.3kg of ionic liquid (2.25kg of ionic liquid [Bmim]OTf and 1.0kg of AlCl 3 Mixed solution) was mixed and added into the reactor, and the electric-assisted cracking reaction occurred for 100 minutes under the condition of high-heat flue gas, temperature 140°C, stirring speed 500r / min, voltage 0.5V, and combustible gas and bio-oil were produced after the cracking was completed;

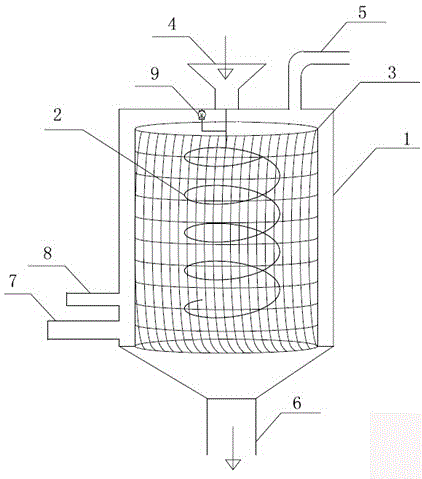

[0020] 2. If figure 1 As shown, the electric assisted cracking reactor that completes the above method includes a cylinder 1, a spiral anode, 2, a grid cylindrical cathode 3, and the spiral anode 2 is arranged in the grid cylindrical cathode 3 and is arranged on the cylinder The motor 9 on the body 1 drives the rotation, the spiral anode 2 and the grid cylindrical cathode 3 are arranged in the cyli...

Embodiment 2

[0023] Embodiment 2: The method for electrochemically strengthening liquid-phase catalytic low-temperature pyrolysis of biomass, the specific content is as follows:

[0024] 1. Mix 2.1kg of rice straw with 6.5kg of ionic liquid (5.0kg of ionic liquid [Emim]Cl and 1.5kg of SnCl 2 mixed liquid) mixed into the reactor, and the carrier gas N 2 , The temperature is 220°C, the stirring speed is 800r / min, and the voltage is 1.2V, and the electric assisted cracking reaction occurs for 80 minutes. After the cracking is completed, combustible gas and bio-oil are produced;

[0025] 2. The structure of the electric-assisted cracking reactor for completing the above method is the same as that in Example 1, except that the spiral anode is a graphite electrode, and the grid cylindrical cathode is a palladium electrode.

[0026] Put the straw into the barrel of the electric cracking reactor from the feed port, close the feed port, N 2 It is introduced from the air inlet, and the ionic liqui...

Embodiment 3

[0028] Embodiment 3: The method for electrochemically strengthening liquid-phase catalytic low-temperature pyrolysis of biomass, the specific content is as follows:

[0029] 1. Mix 5.4kg tobacco leaves with 18.9kg ionic liquid (16kg ionic liquid [Bmim]Cl and 2.9kgFeCl 2 mixed liquid) mixed into the reactor, and the carrier gas N 2 , The temperature is 300°C, the stirring speed is 1000r / min, and the voltage is 10V, and the electric cracking reaction occurs for 120min. After the cracking is completed, combustible gas and bio-oil are produced;

[0030] 2. The structure of the electric-assisted cracking reactor for completing the above method is the same as that of Example 1, except that the spiral anode is a gold electrode, and the grid cylindrical cathode is a graphite electrode.

[0031] Put the tobacco leaves into the barrel of the electric cracking reactor from the feed port, close the feed port, N 2 It is introduced from the air inlet, and the ionic liquid is transported f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com