Nickel plated copper product containing nickel-cobalt alloy clad layer, and preparation method and application thereof

A technology of nickel-cobalt alloy and nickel-plated copper, which is applied in the field of battery manufacturing, can solve the problems of being unable to meet the requirements of high-rate lithium-ion battery negative electrode tabs, reducing material corrosion resistance, and not clearly pointing out, so as to achieve fine grain size. Effects of oxidization, prevention of grain growth, and recovery of metal ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

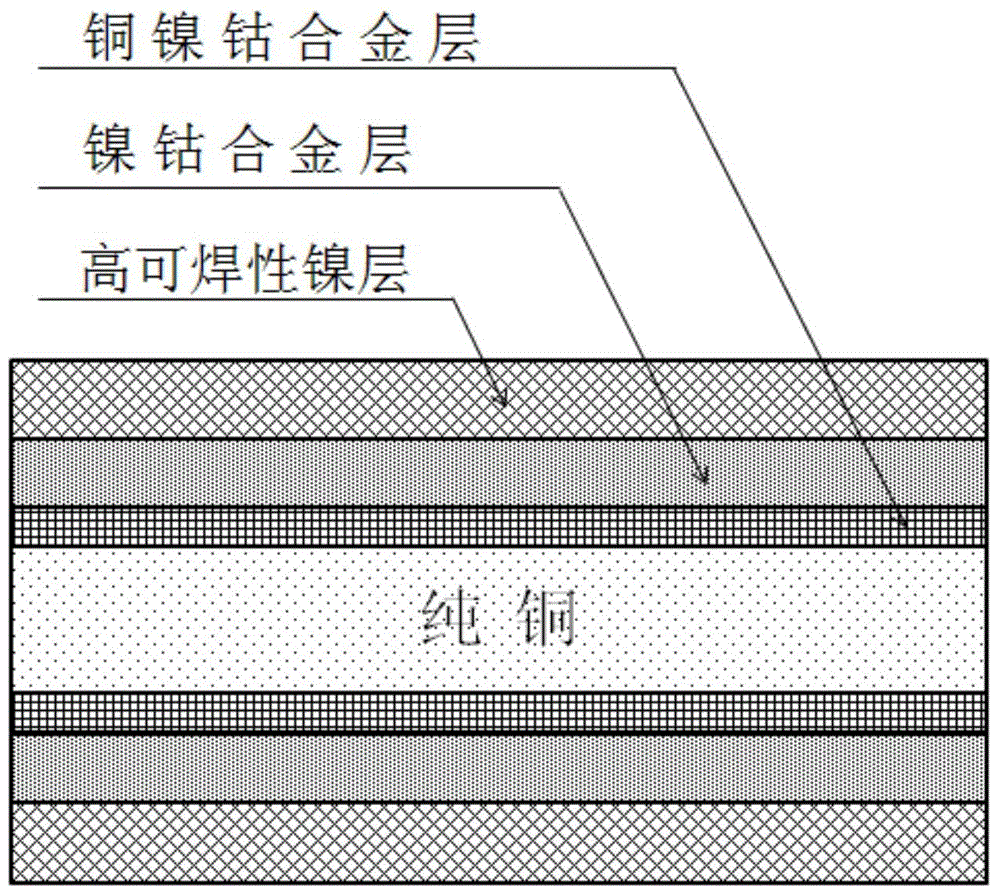

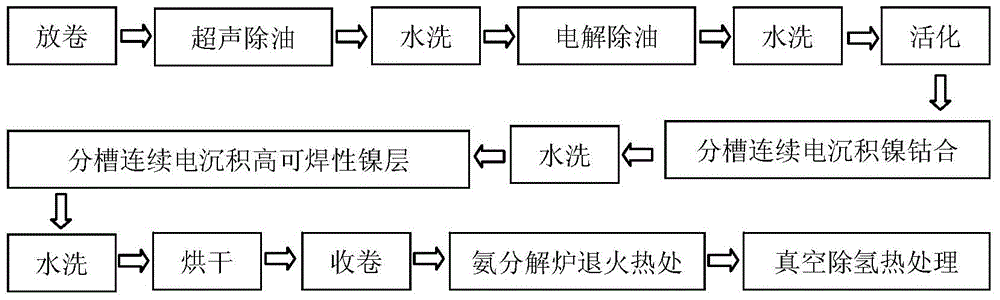

[0058] A preparation method of a nickel-plated copper material containing a nickel-cobalt alloy coating of the present invention is used for high-rate lithium-ion battery tab materials, using semi-hard pure copper as the base material, and electrodepositing a thickness of 0.4 μm crystal on both sides of the base with a small current. A nickel-cobalt alloy coating with a particle size of 50-100nm, and then electrodeposit a high-solderability nickel coating with a thickness of 1.4μm and a grain size of 100-600nm on the nickel-cobalt alloy coating, and finally pass the material through 550°C for 2h Reducing atmosphere heat treatment and 200°C 4h dehydrogenation heat treatment process to form a 0.3μm copper-nickel-cobalt alloy layer.

specific Embodiment approach

[0059] Its specific implementation method comprises the following steps:

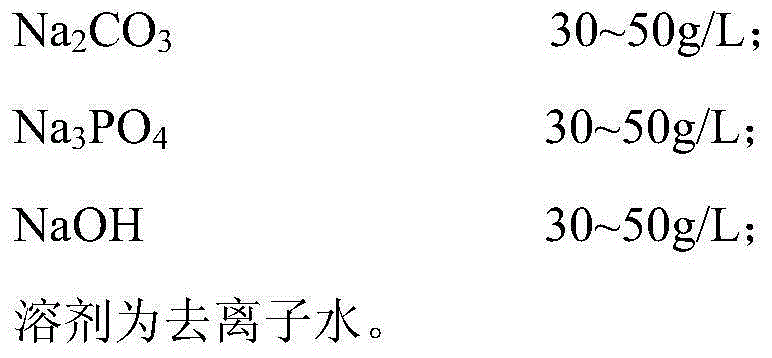

[0060] (1) Pretreatment: Ultrasonic degreasing, electrolytic degreasing and activation treatment are performed on the pure copper strip. The ultrasonic degreasing temperature is 45°C, the ultrasonic frequency is 20kHz, and the degreasing time is 1min. The degreasing liquid formula is sodium carbonate 30g / L, trisodium phosphate 20g / L, and sodium hydroxide 30g / L. Electrolytic degreasing temperature is 55℃, current density is 5A / dm 2 , oil removal time 1.5min, oil removal formula sodium carbonate 30g / L, trisodium phosphate 20g / L, sodium hydroxide 30g / L. The concentration of sulfuric acid in the activation treatment is 8%, the solution temperature is 25°C, and the treatment is about 1 min.

[0061] (2) Electrodeposited nickel coating: including electrodeposited nickel-cobalt alloy layer and electroplated high solderability nickel coating. The formula of nickel-cobalt alloy solution is nickel sulfate 300g...

Embodiment 2

[0075] The preparation method of a nickel-plated copper material containing a nickel-cobalt alloy coating of the present invention is used for high-rate lithium-ion battery tab materials, with soft pure copper as the base material, and a small current electrodeposition thickness of 0.2 μm crystal grains on both sides of the base Nickel-cobalt alloy coating with a size of 50-100nm, and then electro-depositing a high-solderability nickel coating with a thickness of 1μm and a grain size of 300-600nm on the nickel-cobalt alloy coating, and finally heat-treating the material in a reducing atmosphere at 2.5h650°C And 260 ℃ 4h dehydrogenation heat treatment process to form a 0.5μm copper-nickel-cobalt alloy layer.

[0076] Its specific implementation method comprises the following steps:

[0077] (1) Pretreatment: Ultrasonic degreasing, electrolytic degreasing and activation treatment are performed on the pure copper strip. The ultrasonic degreasing temperature is 50°C, the ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com