In-situ grown three-dimensional multi-structural cobaltosic oxide/carbon composite micro-nanomaterial and controllable preparation method thereof

A technology of in-situ growth of cobalt trioxide, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., to achieve the effects of wide application range, strong operability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

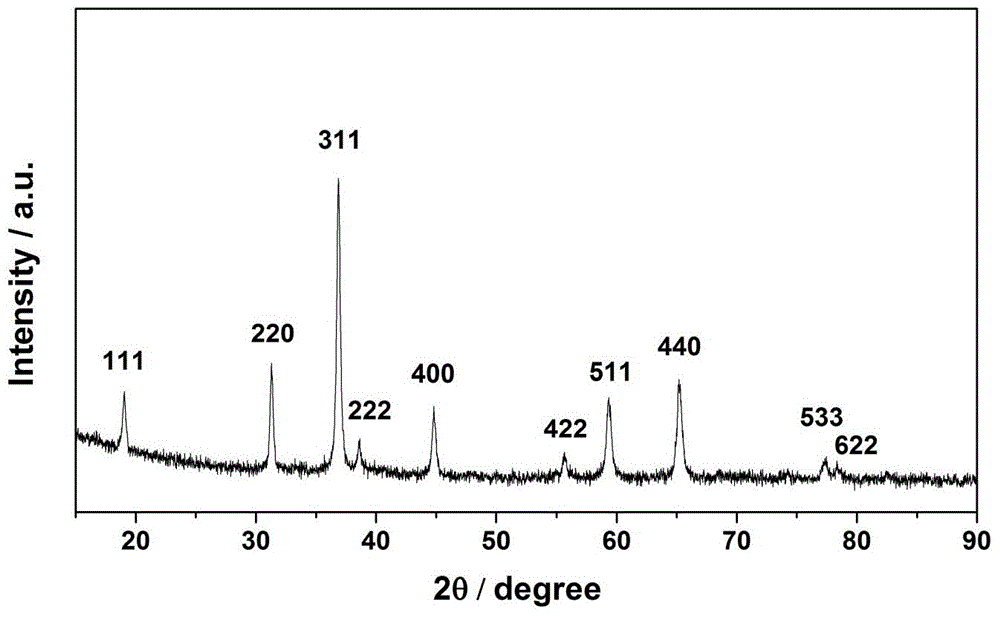

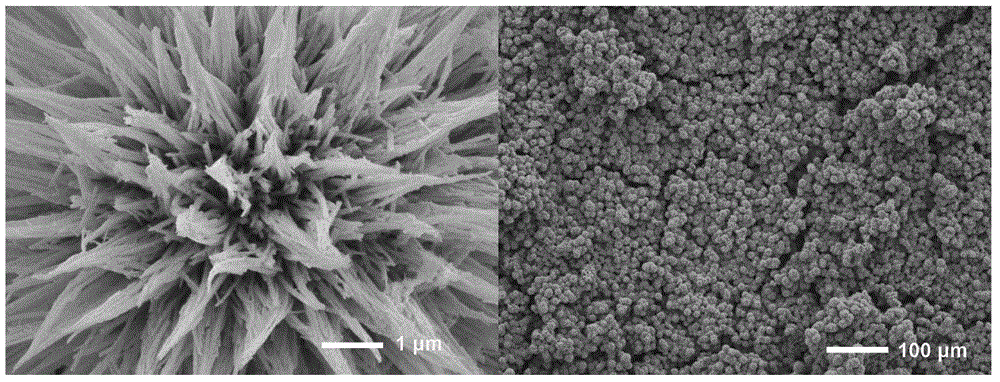

[0034]Mix 4mmol cobalt nitrate hexahydrate and 10mmol ammonium fluoride evenly, add 30ml deionized water to disperse and stir for 5min. Dissolve 20mmol urea in 20ml deionized water, add the above solution, disperse and stir for 5min. The above mixed solution was transferred to the polytetrafluoroethylene liner of the autoclave, put into the pretreated base conductive glass, and reacted at 110°C for 5 hours at a closed constant temperature, and then cooled naturally to room temperature. The obtained reaction product was washed 3 times with deionized water, dried at 80°C for 4h, and calcined at 300°C for 6h at a heating rate of 1°C / min to obtain a dandelion-shaped three-dimensional hierarchical structure Co 3 o 4 micro-nano materials.

[0035] Co 3 o 4 The micro-nano material is immersed in 1M carbon-rich compound solution for 12 hours. The above product was calcined at a rate of 1°C / min in nitrogen, and calcined at 300°C for 6 hours to obtain a dandelion-shaped three-dimen...

Embodiment 2

[0038] Mix 4mmol cobalt nitrate hexahydrate and 20mmol ammonium fluoride evenly, add 30ml deionized water to disperse and stir for 5min. Dissolve 20mmol urea in 20ml deionized water, add the above solution, disperse and stir for 5min. The above mixed solution was transferred to the polytetrafluoroethylene liner of the autoclave, put into the pretreated substrate conductive glass, and reacted at 100°C for 5 hours at a closed constant temperature, and then cooled naturally to room temperature. The obtained reaction product was washed 3 times with deionized water, dried at 80°C for 5h, and calcined at 400°C for 4h at a heating rate of 1°C / min to obtain the sunflower flower-shaped three-dimensional hierarchical structure Co 3 o 4 micro-nano materials.

[0039] Co 3 o 4 The micro-nano material is immersed in a 0.5M carbon-rich compound solution for 24 hours. The above product was calcined at a rate of 1°C / min in nitrogen, and calcined at 500°C for 4 hours to obtain a sunflower...

Embodiment 3

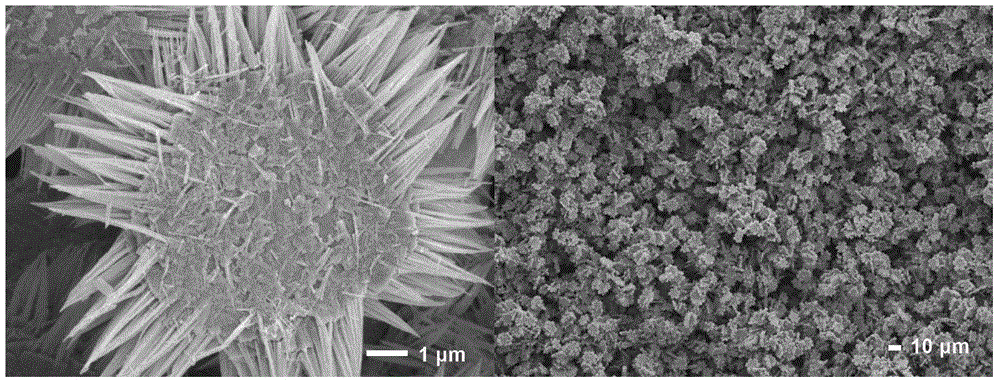

[0042] Mix 5 mmol of cobalt chloride hexahydrate and 10 mmol of ammonium fluoride evenly, add 30 ml of deionized water to disperse and stir for 5 min. Dissolve 25mmol urea in 20ml deionized water, add the above solution, disperse and stir for 5min. The above mixed solution was transferred to the polytetrafluoroethylene liner of the autoclave, put into the pretreated base conductive glass, and reacted at 150°C for 5 hours at a closed constant temperature, and then cooled naturally to room temperature. The obtained reaction product was washed 3 times with deionized water, dried at 90°C for 3h, and calcined at 500°C for 3h at a heating rate of 1°C / min to obtain the thorn-shaped three-dimensional hierarchical structure Co 3 o 4 micro-nano materials.

[0043] Co 3 o 4 The micro-nano material is immersed in a 0.1M carbon-rich compound solution for 36 hours. The above product was calcined at a heating rate of 1°C / min in nitrogen, and calcined at 600°C for 2 hours to obtain a thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com