Fusant mixture, preparation method of fusant mixture, and method for producing organic fertilizer

A technology of yeast fusion bacteria and mixed bacteria agent, which is applied in the preparation of organic fertilizers, methods based on microorganisms, organic fertilizers, etc., can solve the problems of large differences in the decomposition speed of organic matter, complex preparation processes, and high costs, and save manpower and energy, simple production process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

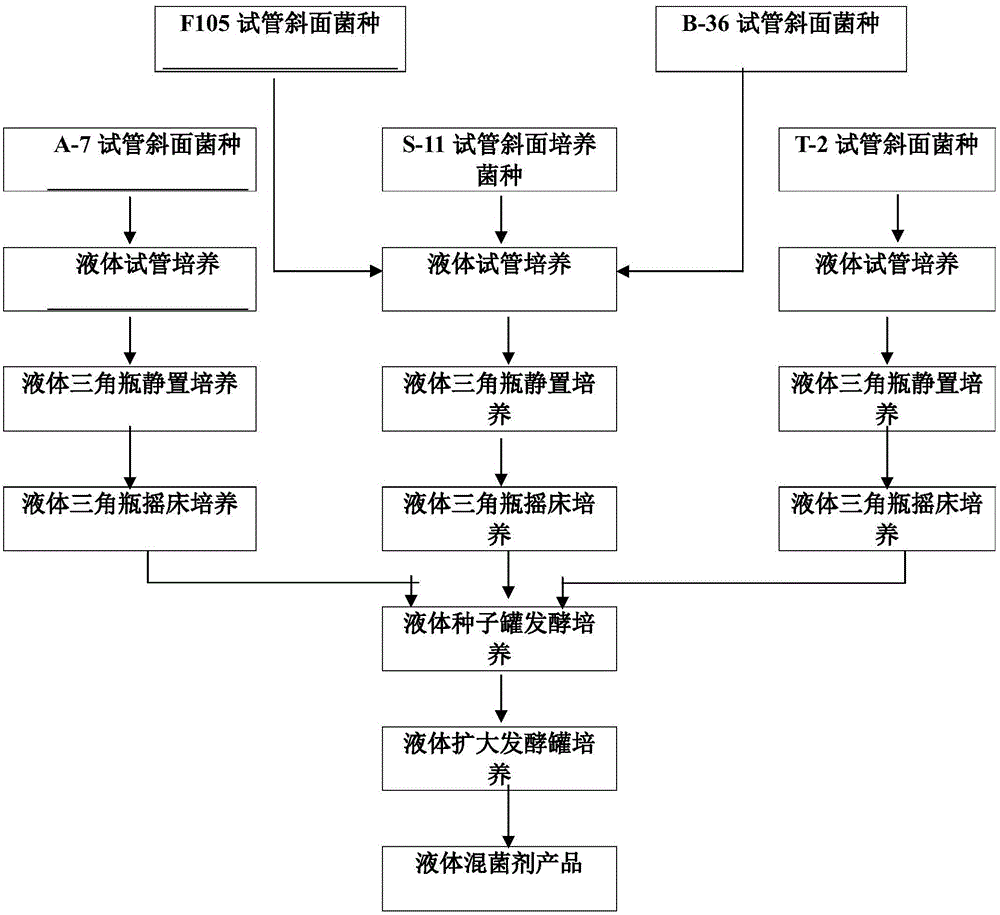

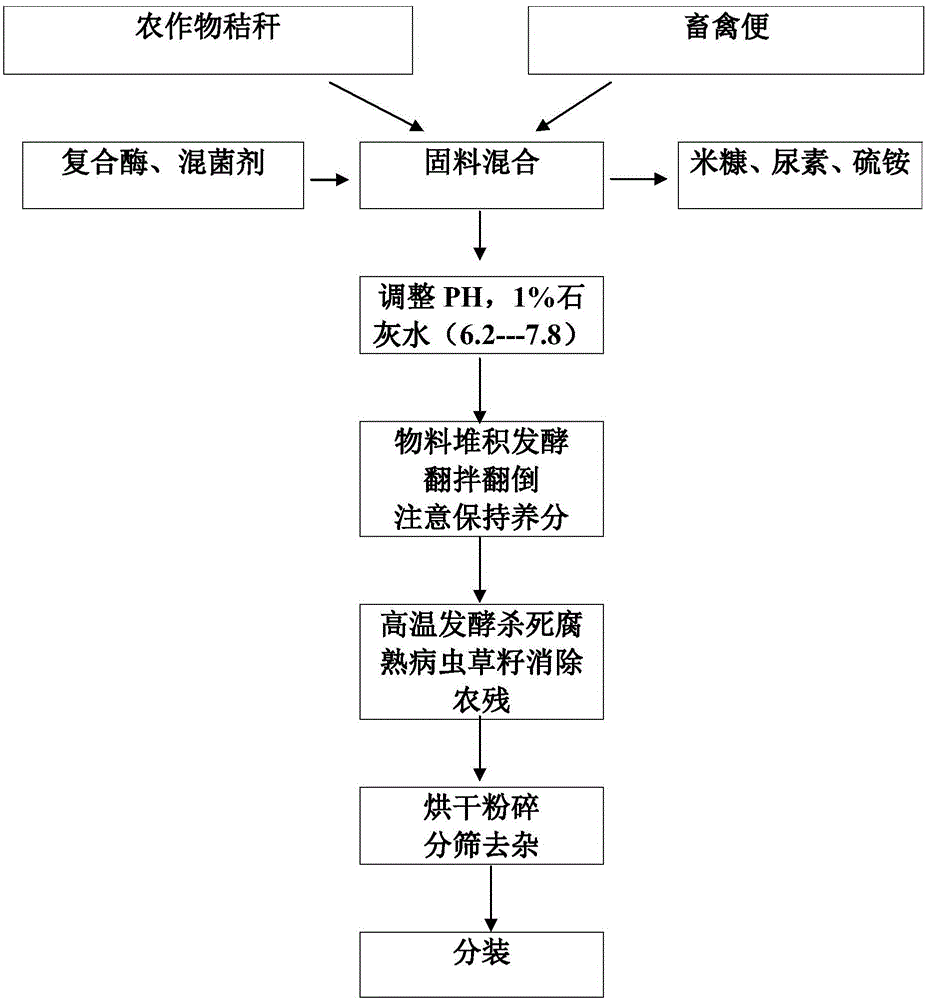

[0045] Embodiment 1: a kind of yeast fusion bacteria mixed bacteria agent, it is characterized in that this mixed bacteria agent comprises thalline and culture medium: wherein said thalline comprises yeast fusion bacteria (Fusantbetween CandidatropicalisandSaccharmycescevisiae) F105, in China Microorganism Strain Preservation Management Committee Preserved by the General Microorganism Center, the address of the depository unit is: Institute of Microbiology, Chinese Academy of Sciences, No. 3, Beichen West Road, Chaoyang District, Beijing. The preservation time is December 30, 2014, and the preservation number is CGMCCNO.10263; Bacillus Licheniformis B-36 was purchased from the China Agricultural Microorganism Culture Collection Center with the number Accc11080; Azotobacter chroococum LGN-09 was preserved in the General Microbiology Center of the China Microbiology Culture Collection Management Committee. The address of the preservation unit is: Chaoyang District, Beijing The In...

Embodiment 2

[0046]Embodiment 2: described yeast fusion bacteria mixed bacteria agent also includes mixed bacteria liquid culture medium and adds ammonium sulfate 1-2g in one liter of fresh bean curd wastewater or vermicelli wastewater or cornstarch wastewater or potato starch wastewater, calcium carbonate 1 -2g, phosphoric acid 0.5-1ml, adjust the pH to 6.2-7.5 with 1% lime water, divide into 500ml Erlenmeyer flasks, the filling volume is 1 / 4 of the capacity of the bottle, then heat through 110-112°C for 30-35 minutes Autoclave, after cooling, get the agar slant test tube strains of yeast fusion bacteria, Bacillus licheniformis, Azotobacter rufosa, Streptomyces and Trichoderma konii respectively, and transfer them to the liquid Erlenmeyer flask culture medium under aseptic conditions respectively. After standing at 28-32°C for 24-72 hours or shaking culture on a shaking table, or aeration and stirring fermentation culture in a fermenter, the fermentation broth is prepared according to its ...

Embodiment 3

[0047] Embodiment 3: the preparation of a kind of yeast fusion bacterium has the following steps: the slant planting and cultivation of alcoholic yeast as the mother species, after 14 hours of shaking culture in liquid medium, carry out pretreatment with EDTA-mercaptoethanol, use 1.5 of cellulase and 0.5 of helicase to enzymatically detach the wall, the time is 2.5 hours, the temperature is 33 ° C, and the protoplasts of alcoholic yeast are obtained; the slant of Candida tropicalis as the mother species is transferred and cultivated: in liquid medium After shaking and culturing for 14 hours, pretreat with EDTA-mercaptoethanol, and use 1.5% cellulase and 0.5% helicase to enzymatically detach the wall for 2.5 hours at a temperature of 33°C to obtain protoplasts of Candida tropicalis; Candida protoplasts were inactivated by 0.1% iodoacetic acid, and then mixed with alcoholic yeast protoplasts at a ratio of 1:1, and the precipitate was suspended in 35% polyethylene glycol (PEG) sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com