Fabrication method of gas sensor based on Pt-doped SNO2 ordered mesoporous film

A gas sensor and thin film technology, applied in the direction of material resistance, etc., can solve the problems of unfavorable large-scale production of devices, affecting the resistance of sensitive layers, heating response to gas, and the sensing layer of gas sensors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) SnO 2 Preparation of sol: the precursor is polyisobutylene- b -Polyethylene oxide block copolymer, anhydrous tin tetrachloride, absolute ethanol and tetrahydrofuran, add the block copolymer to the absolute ethanol and tetrahydrofuran solution to prepare a sol at a mass ratio of 1:24:25, and ultrasonically vibrate 30 min, obtain transparent solution A, by mass ratio 1:6 with anhydrous SnCl 4 Dissolve in absolute ethanol to obtain solution B, slowly add solution B to A while stirring, and stir for 30 min to obtain SnO 2 Sol;

[0021] (2) Pt-doped SnO 2 Preparation of sol: The dopant chloroplatinic acid is added dropwise to the SnO obtained in step (1) at a mass ratio of 1.0% to tin 2 In the sol, the obtained sol was magnetically stirred at 500 r / min at room temperature for 24 h, and then aged at room temperature for 24 h;

[0022] (3) Keep the relative humidity of the air at 10%, drop the sol obtained in step (2) onto the polished surface of the silicon substrate...

Embodiment 1

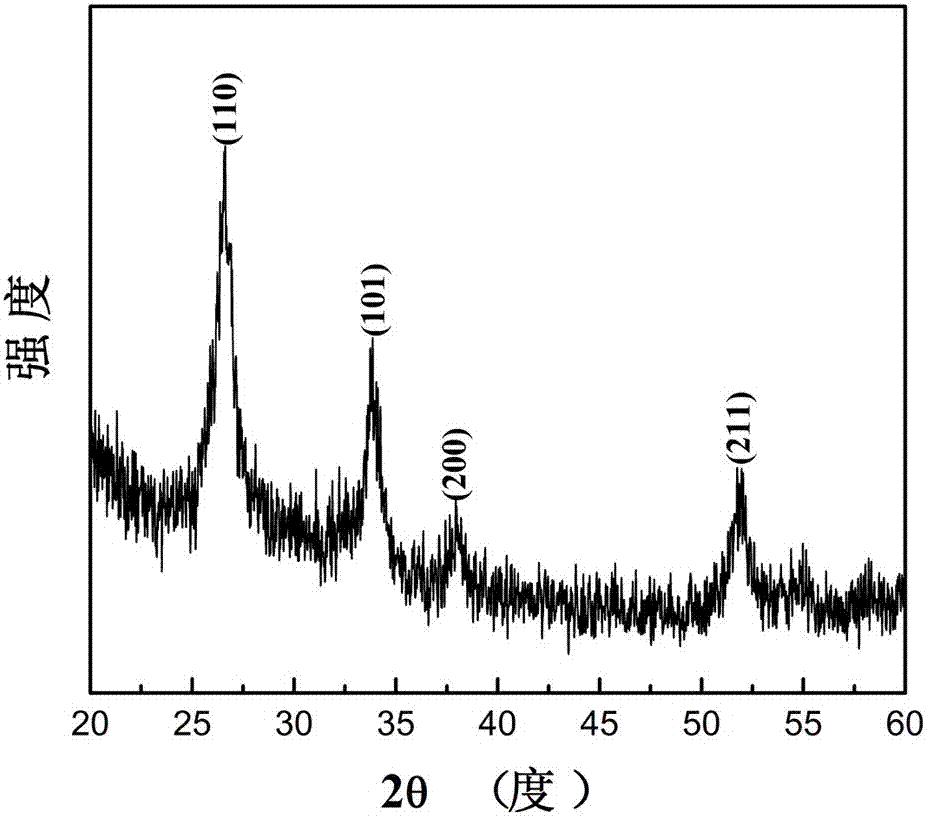

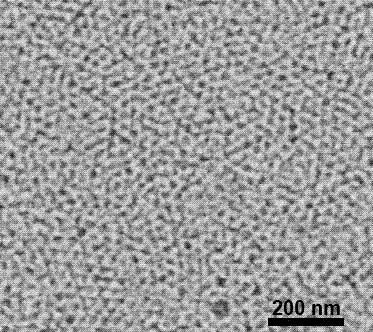

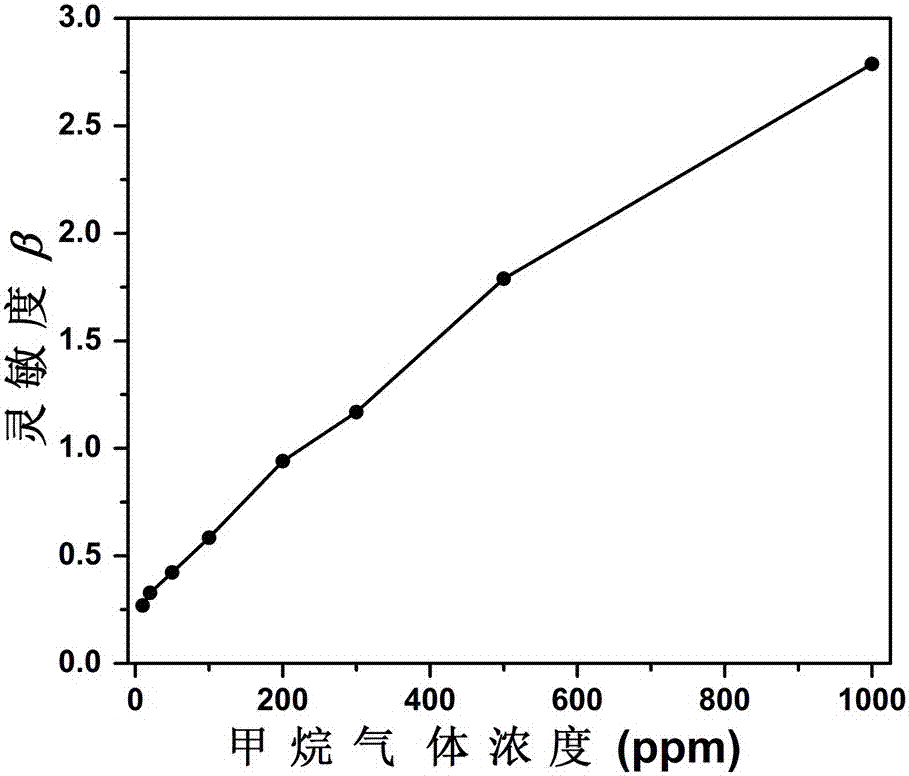

[0025] Example 1 Prepared Pt-doped SnO 2 The X-ray diffraction pattern analysis results of ordered mesoporous films are as follows: figure 1 shown, indicating that SnO 2 The peak position of the characteristic diffraction peak is completely consistent with the standard card (JCPDS 41-1445), and no Pt peak appears, indicating that the prepared material is crystalline SnO 2 , and Pt has been doped in SnO 2 in the lattice; scanning electron microscopy ( figure 2 ) photos show that its morphology is a mesoporous structure with regular pores approximately vertical, with a pore diameter of about 15 nm; the sensitive properties are as follows image 3 As shown, Pt-doped SnO2 The ordered mesoporous film sensor has high sensitivity to methane.

Embodiment 2

[0027] (1) SnO 2 Preparation of sol: the precursor is polyisobutylene- b - Polyethylene oxide block copolymer, anhydrous tin tetrachloride, absolute ethanol and tetrahydrofuran, add the block copolymer to the absolute ethanol and tetrahydrofuran solution to prepare a sol at a mass ratio of 2:24:25, and ultrasonically vibrate 30 min, obtain transparent solution A, by mass ratio 1:6 with anhydrous SnCl 4 Dissolve in absolute ethanol to obtain solution B, slowly add solution B to A while stirring, and stir for 30 min to obtain SnO 2 Sol;

[0028] (2) Pt-doped SnO 2 Preparation of sol: The dopant chloroplatinic acid is added dropwise to the SnO obtained in step (1) at a mass ratio of 2.5% to tin 2 In the sol, the obtained sol was magnetically stirred at 500r / min at room temperature for 24 h, and then aged at room temperature for 24 h;

[0029] (3) Keep the relative humidity of the air at 15%, and drop the sol obtained in step (2) onto the polished surface of the silicon subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com