Viscose industry waste water treating method and device

A treatment method and viscose fiber technology, applied in textile industry wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of wastewater, increased product cost, and decreased economic benefits. , to achieve the effect of low production and operating costs, low equipment requirements, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

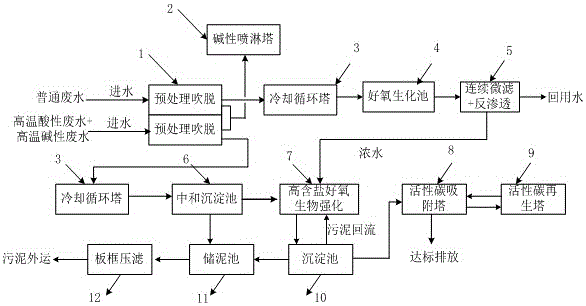

[0040] A kind of processing method of viscose fiber waste water:

[0041] (1) First, viscose wastewater should be divided into high-salt and low-salt wastewater according to its salinity, and then treated separately;

[0042] (2) Physicochemical pretreatment: Blow off the waste water, and the hydrogen sulfide gas blown out is subjected to alkaline elution through the spray tower, and the waste liquid is recycled for resources; Sodium hydroxide, 5% concentration) elution, elution waste liquid for resource recycling;

[0043] (3) Neutralize high-salt wastewater and cool it through a cooling tower, and use waste carbide slag to further neutralize the neutralized wastewater to obtain high-salt neutral wastewater; step (3) low-salt wastewater does not need to be Bioaugmentation treatment, direct use of activated sludge method for biochemical treatment, the continuous microfiltration (Dow membrane, Q max =300m3 / h·set, 2000L / h / only 20 pieces / set) + reverse osmosis membrane (Dow mem...

Embodiment 2

[0050] Physicochemical pretreatment: Blow off the wastewater, carry out alkaline elution of the hydrogen sulfide gas blown out through the spray tower, and recycle the eluted waste liquid; the viscose chemical fiber wastewater is accompanied by the generation of wastewater, and there is a large amount of hydrogen sulfide Gas generation, this kind of waste gas is washed by alkaline spray tower. The chemical reaction in the alkali spray tower is driven by the pump to carry out circular spraying, and the hydrogen sulfide gas and carbon disulfide gas discharged from the alkali spray tower meet the standard discharge. Using this method to absorb hydrogen sulfide waste gas has high efficiency and large processing capacity per unit time, and solves the problems of environmental pollution and production safety hazards caused by hydrogen sulfide waste gas discharge. Specifically, the treated waste lye containing sodium hydroxide solution and alkali fiber containing hemicellulose is rea...

Embodiment 4

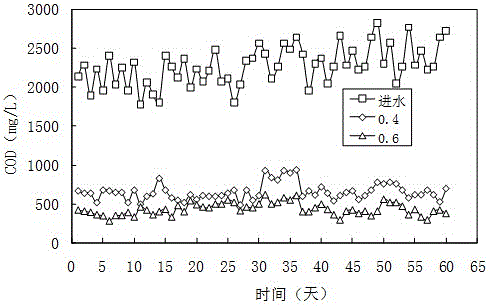

[0068] After the pretreated high-temperature acidic wastewater is neutralized, add bacterial preparations (bacteria Bacillus subtilis, 0.5kg / day ton of wastewater. The concentration of bacteria is 1×10 4 pc / ml, strain Bacillus subtilis dry bacteria + volcanic mud, the weight ratio is 1:1), the change of wastewater COD corresponding to different dosages is shown in image 3 : Adding bacterial preparations once is 0.4kg of bacterial preparations and 0.6kg of bacterial preparations per ton of wastewater in one day’s water volume. image 3 The results show that the COD is always below 400mg / L when 0.6kg of bacterial preparation is added at one time. It can even reach 200mg / L; when the bacterial preparation is 0.4kg at one time, its COD runs below 500-600mg / L. It can be seen that with the different doses of bacterial preparations added at one time, the degree of COD degradation has certain changes. On the basis of considering the cost, when the wastewater discharge standard is le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com