A ceramic composite diaphragm with thermal shutdown function and its application

A ceramic composite, thermal shutdown technology, applied in the field of lithium-ion batteries, can solve the problems of poor uniformity, leakage, powder drop, etc., and achieve the effect of increasing the surface area and improving the wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

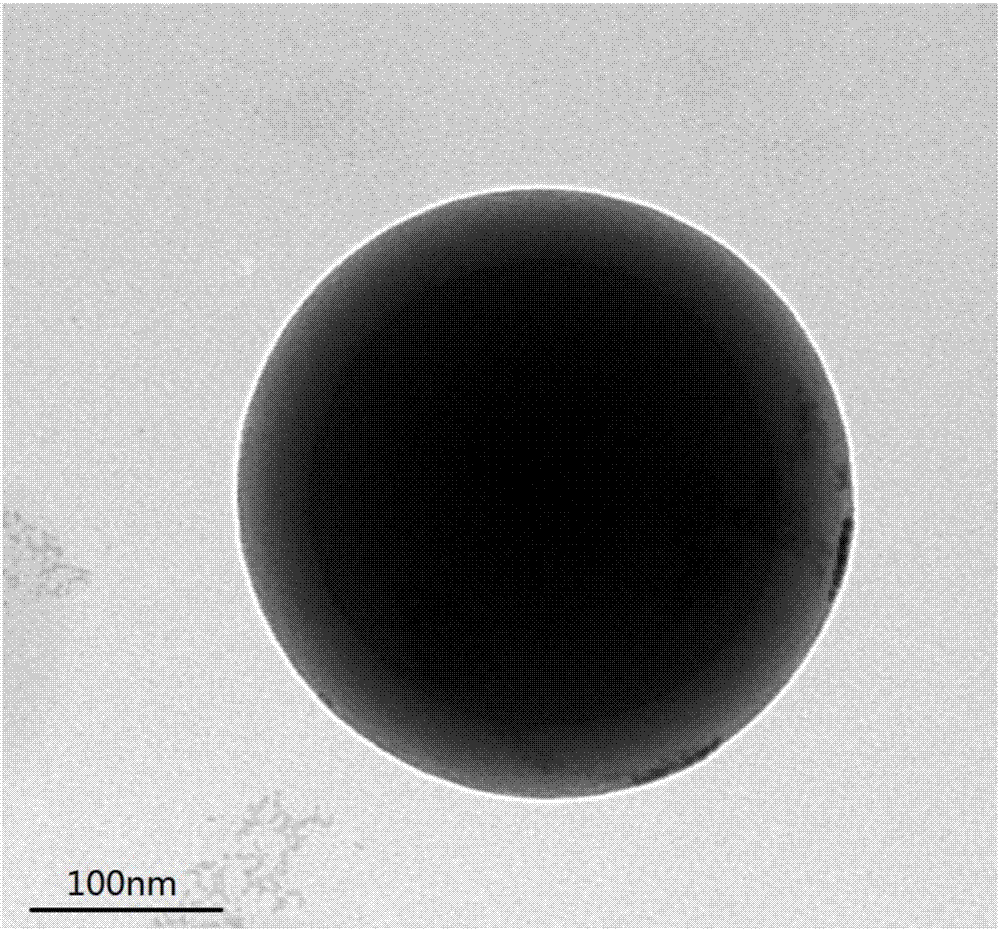

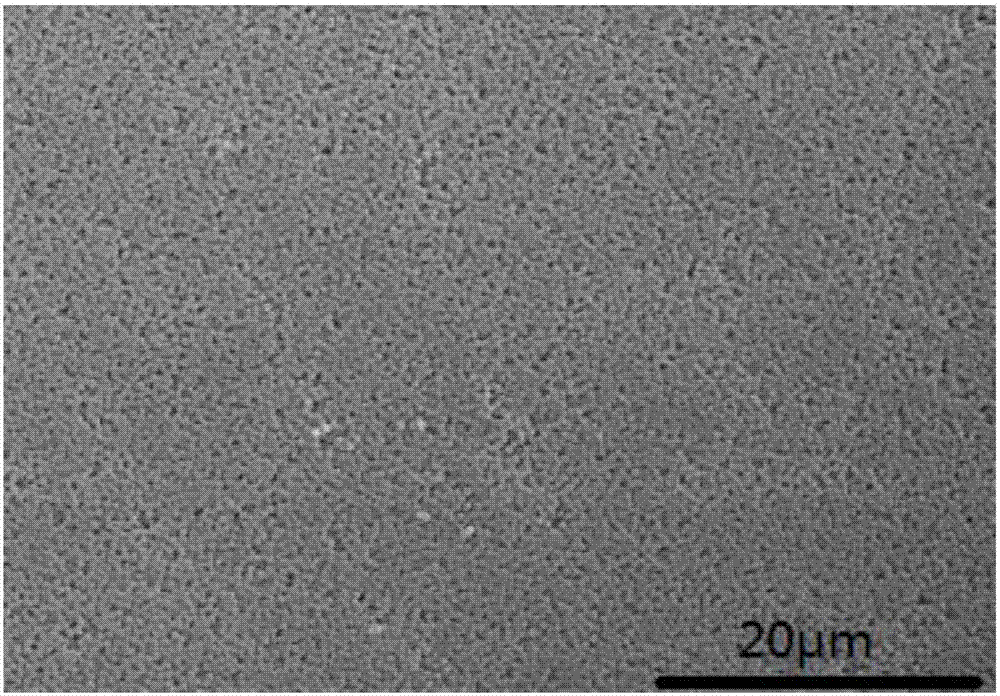

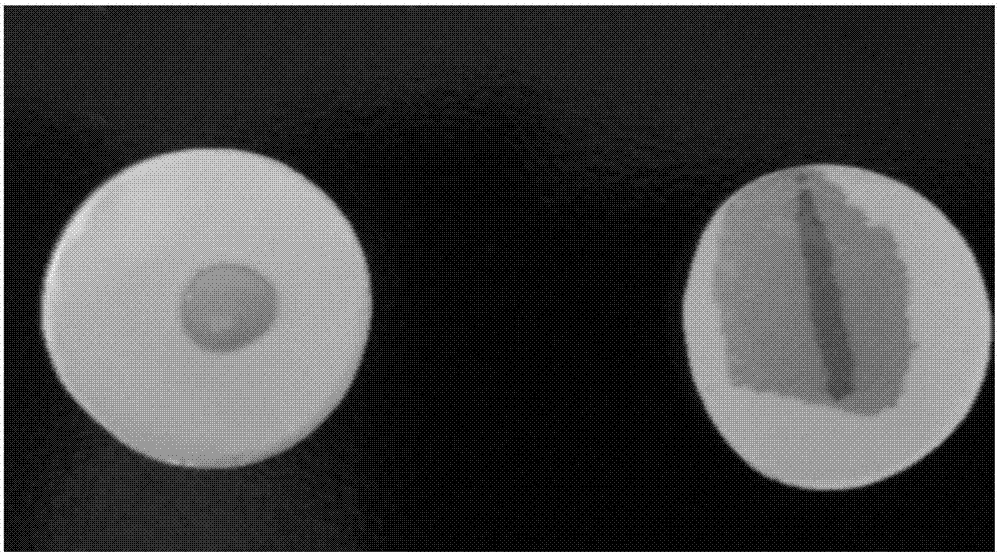

[0046] Add 30mL tetraethyl orthosilicate to 350mL absolute ethanol at room temperature, then quickly add 30mL water and 12mL 14mol / L ammonia water mixture, stir and react at a speed of 200r / min for 3h to obtain a silica particle dispersion, Silica particles are around 400nm. Dissolve 0.1 g of silicon dioxide and 0.25 g of polyethylene solution (40% solid content) into 1 L of aqueous solution, and mechanically stir for 10 h to obtain a uniform mixed solution. Spray drying to obtain core-shell structure particles with silicon oxide as the core and polyethylene as the shell. Characterized by transmission electron microscopy, the thickness of the shell layer can be controlled at 2nm-1μm by adjusting the input amount of polyethylene emulsion. Take 0.2g of core-shell particles and 0.1g of vinylidene fluoride (binder) and disperse them in 50mL of N-methylpyrrolidone. 2 Coated on the polyethylene separator, and after drying, a ceramic composite separator with thermal shutdown functi...

Embodiment 2

[0055] Dissolve 1 g of aluminum oxide and 2.50 g of polypropylene solution (45% solid content) into 10 L of aqueous solution, and mechanically stir for 15 h to obtain a uniform mixed solution. Spray drying to obtain core-shell structure particles with aluminum oxide as the core and polypropylene as the shell. Take 0.8g of core-shell structure particles, 0.2g of polyvinylidene fluoride-hexafluoropropylene (binder) and disperse in 100mL of acetone, and use casting method in 1m 2 Coated on the polypropylene diaphragm, and after drying, a ceramic composite diaphragm with thermal shutdown function is obtained.

Embodiment 3

[0057] Dissolve 10 g of magnesium oxide and 25 g of polyethylene-propylene solution (50% solid content) into 100 L of aqueous solution, and mechanically stir for 20 h to obtain a uniform mixed solution. Spray drying to obtain core-shell structure particles with magnesium oxide as the core and polyethylene-propylene copolymer as the shell. Take 10g of core-shell structure particles, 0.2g of hydroxymethyl cellulose and 0.3g of styrene-butadiene rubber and disperse them in 100mL of water, and coat them on a 20cm×6m polyethylene diaphragm on a small coating machine. Break function ceramic composite diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com