Composite membrane and preparation method thereof

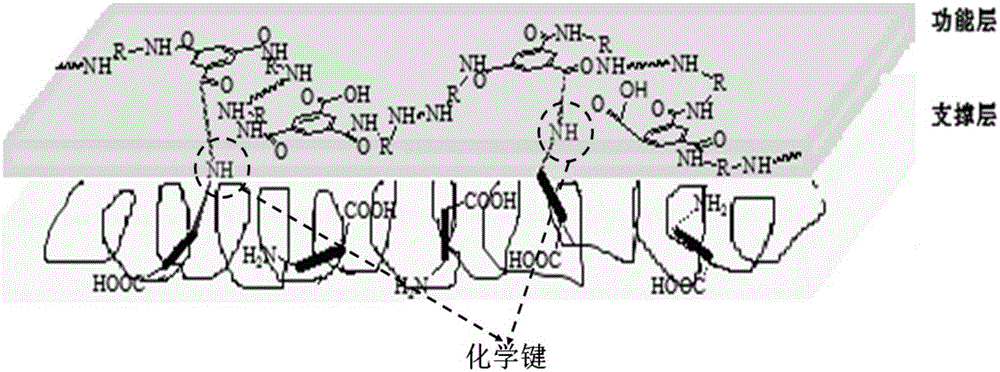

A composite membrane and base membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of limited improvement in the degree of bonding between the base membrane and the functional layer, achieve good application prospects, and improve the firmness of the bond The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] a Preparation of base film:

[0016] Add 120g of N-methylpyrrolidone and 14g of polyethersulfone into a reactor equipped with a stirring paddle, activate at 500°C for 1 hour, add 4g of calcium chloride, raise the temperature to 50°C under nitrogen protection, and stir to form a homogeneous solution , cooled to room temperature, added 4.32g of p-phenylenediamine, cooled in an ice-water bath after dissolving, added 8.56g of terephthaloyl chloride, and stirred for 1 hour to obtain a casting solution. The above-mentioned blend solution was vacuum-degassed for 12 hours, then evenly scraped on a clean glass plate, and immersed in a coagulation bath of 30 wt% ethanol aqueous solution to form a film. The pure water flux of the flat membrane prepared at room temperature is 160L.m -2. h -1. bar, PEG20000 rejection rate 98%.

[0017] b Preparation of composite membrane

[0018] The base film is immersed in an aqueous solution of m-phenylenediamine with a mass concentration of ...

example 2

[0025] a Basement film preparation

[0026] According to the following components and ingredients: 80wt% N,N-dimethylacetamide, 5wt% sulfonated polyethersulfone, 3.5wt% lithium chloride, wherein the lithium chloride was activated at 600°C for 4 hours in a nitrogen atmosphere; The system was heated up to 65°C, stirred to a homogeneous solution, cooled to room temperature and added a certain amount of p-phenylenediamine, after dissolving, cooled to 0°C in an ice-water bath, then added stoichiometric terephthaloyl chloride, stirred for 2 hours to obtain a cast film liquid. After vacuum defoaming the above blend solution for 24 hours, evenly scrape-coat it on a clean glass plate, and immerse it in an aqueous solution of 10wt% N,N-dimethylacetamide to form a film. The pure water flux of the flat membrane prepared at room temperature is 250L.m -2. h -1 , PEG20000 rejection rate is 91%.

[0027] b Preparation of composite membrane

[0028] The base film was soaked in the aqueous...

example 3

[0030] a Basement film preparation

[0031] Set the intrinsic viscosity to 2.2dl.g -1 The cellulose diacetate is added in the solvent dimethyl sulfoxide, according to the following components and composition batching: dimethyl sulfoxide 65wt%, cellulose diacetate 12wt%, calcium chloride 5.6wt%, triethylamine 1.4wt% %, in which calcium chloride was activated at 500°C for 4 hours; heated to 50°C under the protection of nitrogen flow, stirred to form a homogeneous solution, cooled to room temperature and added a certain amount of p-phenylenediamine, and cooled to 0 in an ice-water bath after dissolving After adding stoichiometric amount of 4,4-diaminodiphenyl ether and terephthaloyl chloride, stir rapidly for 3 hours to obtain a casting solution.

[0032] Slowly pour the above blend into a hollow fiber spinning kettle, heat to 50° C., and vacuum defoam for 24 hours, then use 20 wt % N-methylpyrrolidone as a coagulation bath. The pure water flux of the composite membrane prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com