SCR flue gas denitrification catalyst and preparation method therefor

A denitration catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of hard agglomeration of large grains, decreased catalytic activity, low denitration efficiency, etc. The effect of remarkable effect and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

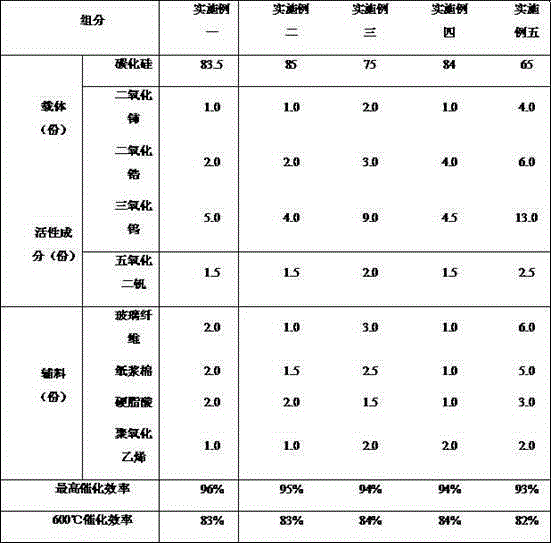

Examples

preparation example Construction

[0033] Further, the catalyst preparation method includes the following processes:

[0034] First, prepare the active ingredient solution, mix ammonium metavanadate, monoethanolamine and water to make ammonium metavanadate solution, and mix ammonium tungstate, oxalic acid solution and water to make ammonium tungstate solution;

[0035] Then, the kneader kneaded, the modified silicon carbide carrier was added to the kneader, and ammonium metavanadate solution, ammonium tungstate solution, glass fiber, pulp cotton, stearic acid, polyethylene oxide were added at a low speed to carry out mixing;

[0036] Finally, the finished product is prepared. After mixing, aging, pre-extrusion, extrusion, primary drying, secondary drying, and roasting are performed to obtain the SCR flue gas denitrification catalyst product.

[0037] Further, in the finished product preparation process, the staling time is 18h-32h; the pre-extrusion pressure is 1Mpa-4Mpa; the extrusion pressure is 2Mpa-5Mpa, t...

Embodiment 1

[0039]1. Carrier preparation: Mix 83.5g of silicon carbide and nitric acid into a hydrothermal kettle and heat until the impurities are dissolved, filter and dry to obtain silicon carbide powder, add 1.0g of ceria and 2.0g of zirconia to the silicon carbide powder , adding sodium borohydride, loading cerium and zirconium simple substances on the surface of silicon carbide, washing, drying, and roasting to obtain a modified silicon carbide carrier;

[0040] 2. Catalyst preparation: first, prepare the active ingredient solution, mix 6.6g ammonium metavanadate, 6.6g monoethanolamine and 50g water to make ammonium metavanadate solution, mix 8.3g ammonium tungstate, 4.1g oxalic acid solution and 100g water Mix to make ammonium tungstate solution;

[0041] Then, the kneader is kneaded, the modified silicon carbide carrier is added to the kneader, the ammonium metavanadate solution and the ammonium tungstate solution are added at a low speed, and then 2.0g glass fiber, 2.0g pulp cott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com