Tissue repair support and its preparation method and use

A tissue repair and composite fiber technology, applied in the field of biomedical devices and their preparation, can solve the problems of foreign matter and immune response, no porous structure, difficult tissue compliance and adhesion, etc., and achieve high porosity and specific surface area, Good compatibility and fit, good restorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

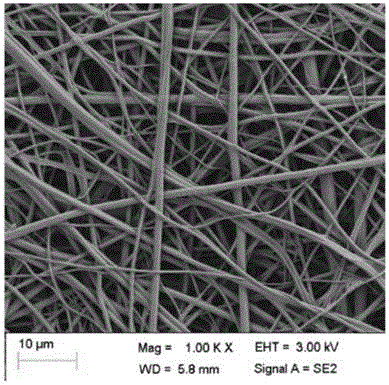

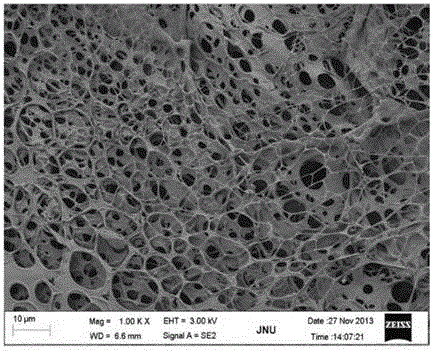

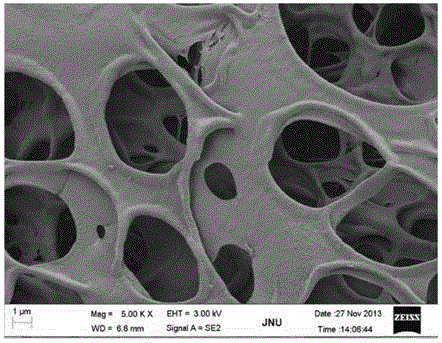

[0086] PCL and collagen are dissolved in hexafluoroisopropanol according to a mass ratio of 4:1 to form a solution with a total concentration of 8% by mass, and then the solution enters the centrifugal spinning machine through a propulsion pump, and the propulsion speed of the propulsion pump is 150g / min. The linear speed of the centrifugal disk is 6000m / min, the solution is spun into fibers rapidly, the spinning temperature is 50°C, after the end, the membrane is removed from the receiver, and then the residual solvent in the membrane is removed to obtain a composite fiber membrane (referred to as material A) . The obtained composite fiber membrane was soaked in 2% by mass gelatin aqueous solution for 5 min, and then freeze-dried to prepare a tissue repair scaffold (referred to as material B).

Embodiment 2

[0088] Dissolve PLLA and gelatin in hexafluoroisopropanol at a mass ratio of 2:1 to form a solution with a total concentration of 8% by mass, then fill the above solution into an electrospinning syringe, and adjust the speed of the microsyringe pump to 4 ml / Hours, adjust the voltage of the high-voltage generator to 23kV, and adjust the receiving distance of the receiving device to 19 cm. The receiving device uses a rotating roller, the moving speed of the electrospinning needle is 15 cm / s, the rotating speed of the receiving roller is 120 cycles / min, and the two needles are electrospun simultaneously for 8 hours. After the end, the film was removed from the receiving roller, and then the residual solvent in the film was removed, soaked in an aqueous solution of 7% by mass gelatin for 30 minutes, and then freeze-dried to prepare tissue repair scaffold E.

Embodiment 3

[0090] PLGA and chondroitin sulfate were dissolved in trifluoroacetic acid at a mass ratio of 4:1 to form a solution with a total concentration of 8% by mass, then the above solution was loaded into an electrospinning syringe, and the rate of the microinjection pump was adjusted to 5 ml / Hours, adjust the voltage of the high-voltage generator to 24kV, and adjust the receiving distance of the receiving device to 19 cm. The receiving device uses a rotating roller, the moving speed of the electrospinning needle is 10 cm / s, the rotating speed of the receiving roller is 150 cycles / min, and the two needles are electrospun at the same time for 8 hours. After the end, the membrane was removed from the receiving roller, and then the residual solvent in the membrane was removed, soaked in an aqueous solution of 2 mass % gelatin for 10 min, and then freeze-dried to prepare a tissue repair scaffold.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com