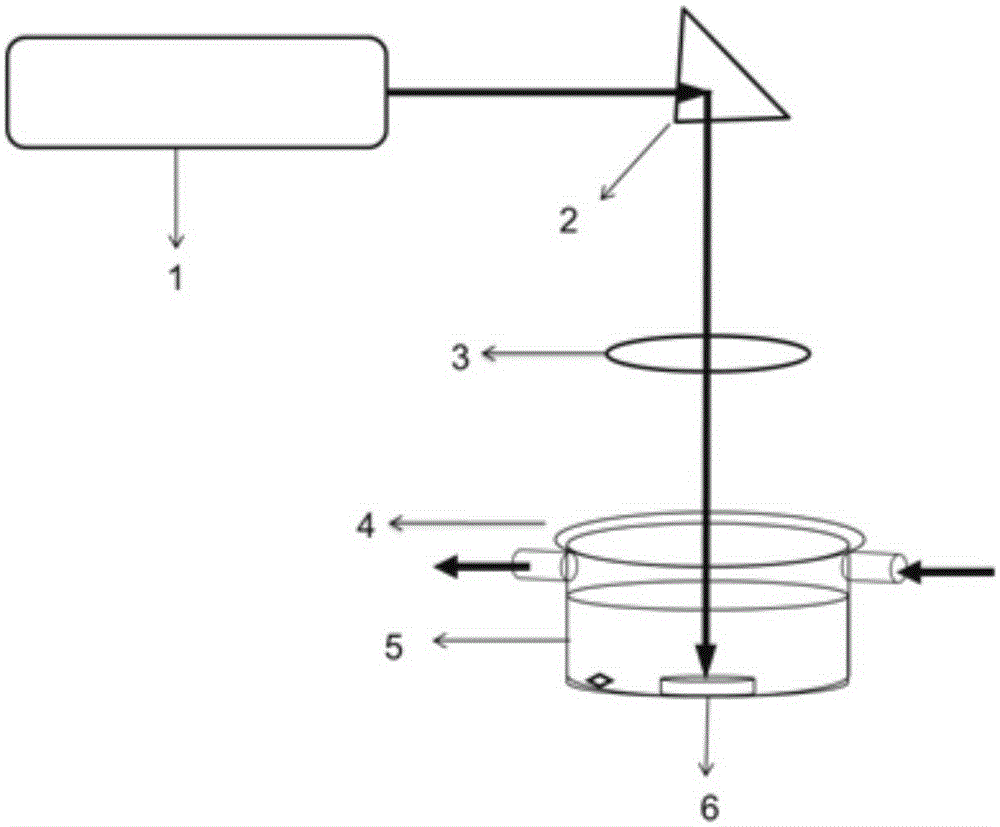

Method for preparing high-purity anti-oxidization base metal nano particles with liquid-phase laser erosion method

A liquid-phase laser ablation and nanoparticle technology, which is applied in nanotechnology and other directions, can solve the problems of unfavorable application, high product impurities, and high risk, and achieve the effects of low cost, good dispersibility, environmental friendliness and no pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1. Choose high-purity Cr metal target as raw material;

[0024] Step 2. Use 500#, 1200#, 2500# sandpaper to polish the Cr metal target repeatedly to remove possible surface oxides and keep the target surface flat and smooth;

[0025] Step 3. Prepare a mixture of methanol and ethanol at a volume ratio of 1:1 as the prepared liquid environment, and use the prepared solution to ultrasonically clean the target to remove impurities;

[0026] Step 4. Put the target into the quartz container and add the methanol and ethanol mixed solution so that the distance between the upper surface of the mixed solution and the surface of the base metal target is 5 mm, and start to continuously pass inert protective gas into the container to remove oxygen;

[0027] Step 5: Repeatedly focus, and select 101mJ laser energy to laser ablate the target for 20 minutes, and simultaneously perform magnetic stirring. Then, the anti-oxidation Cr metal nano particles with the carbon coating protective la...

Embodiment 2

[0030] Step 1. Select high-purity Fe metal target as raw material;

[0031] Step 2. Use 500#, 1200#, 2500# sandpaper to repeatedly sand the Fe metal target to remove possible surface oxides and keep the target surface flat and smooth;

[0032] Step 3. Prepare the n-hexane solution as the prepared liquid environment, and use the prepared solution to ultrasonically clean the target to remove impurities;

[0033] Step 4. Put the target into a quartz container and add n-hexane to make the distance between the upper surface of the mixed solution and the surface of the base metal target 10 mm, and start to continuously pass inert protective gas into the container to remove oxygen;

[0034] Step 5: Repeatedly focus, and select 300mJ laser energy to laser ablate the target for 30 minutes, and perform magnetic stirring at the same time. Afterwards, the anti-oxidation Fe metal nanoparticles with carbon-coated protective layer can be obtained.

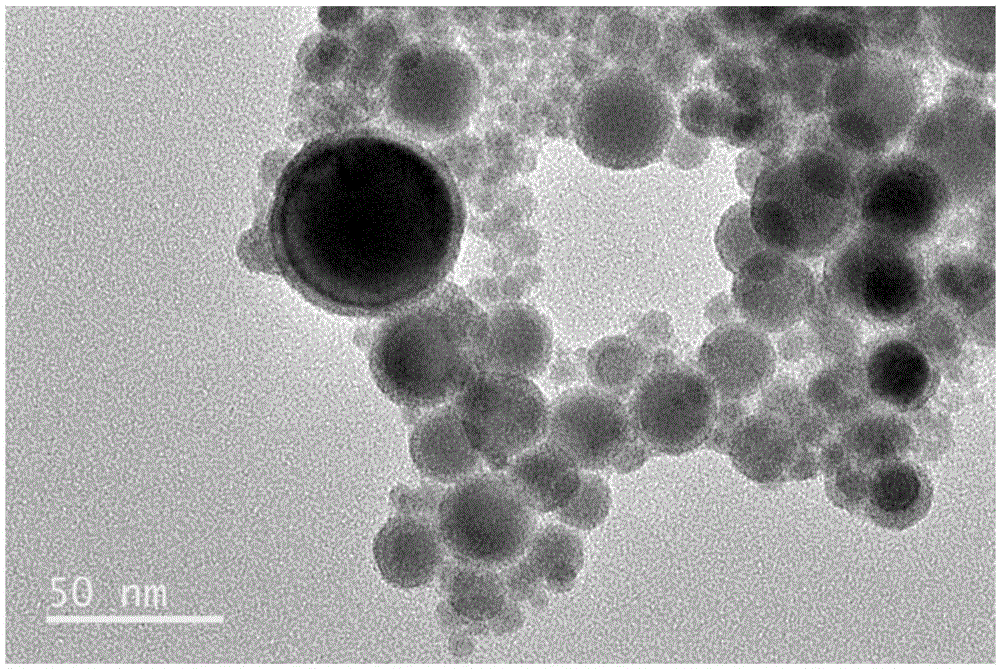

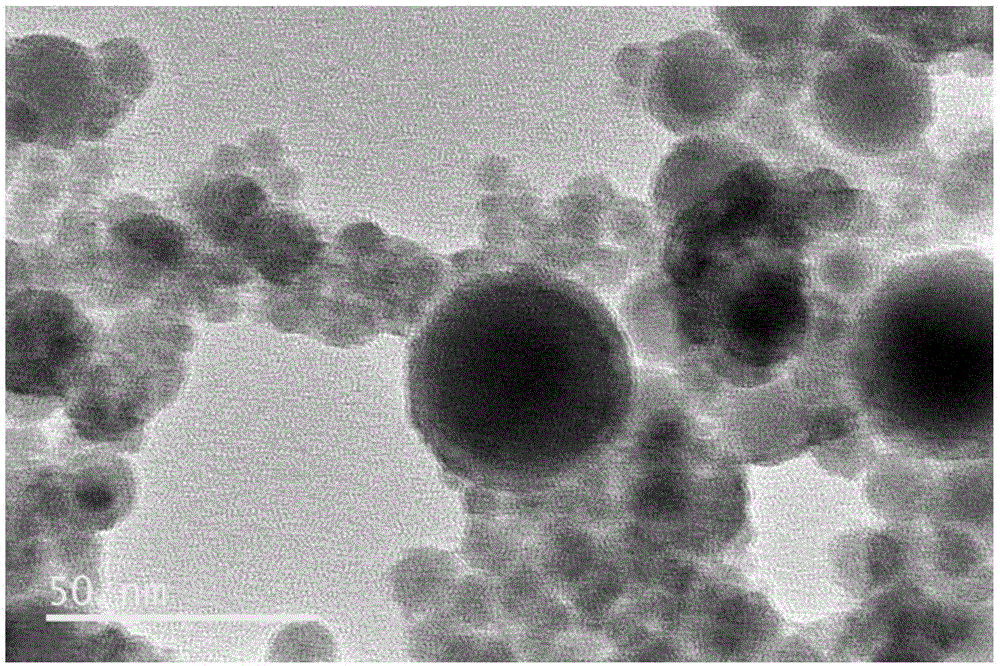

[0035] Observe the prepared anti-oxidation Fe metal...

Embodiment 3

[0037] Step 1. Select high-purity Mn metal target as raw material;

[0038] Step 2. Use 500#, 1200#, 2500# sandpaper to polish the Mn metal target repeatedly to remove possible surface oxides and keep the surface of the target flat and smooth;

[0039] Step 3. Prepare the n-heptane solution as the prepared liquid environment, and use the prepared solution to ultrasonically clean the target to remove impurities;

[0040] Step 4. Put the target into a quartz container and add n-hexane, and start to continuously pass inert protective gas into the container to remove oxygen;

[0041] Step 5. Focusing is repeated, and 233mJ laser energy is selected to laser ablate the target for 40 minutes, and magnetic stirring is performed at the same time. Afterwards, the oxidation-resistant Mn metal nanoparticles with carbon-coated protective layer can be obtained.

[0042] Figure 4 In order to prepare the ultraviolet-visible absorption pattern of the anti-oxidation manganese metal nanoparticles, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com