Metal-chelating water-based styrene-acrylic emulsion and preparation method thereof

A water-based styrene-acrylic emulsion and metal chelation technology, used in anti-corrosion coatings and other directions, can solve the problems of poor salt spray resistance, easy decomposition, secondary corrosion of metal surfaces, etc., to improve corrosion resistance and salt spray resistance, The effect of improving mechanical strength and excellent environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the aqueous styrene-acrylic emulsion of metal chelation of the present invention comprises the following steps:

[0035] (1), synthesis stage

[0036] A1: Preparation of pre-emulsion, add 35% formula water and 20% formula emulsifier into the pre-emulsification tank, turn on the mixer, and put in the formula styrene, butyl acrylate, isooctyl acrylate, Acrylic acid and chelating agent, stirring for 15-30 minutes;

[0037] B1: Add 65% of the formula amount of water and 80% of the formula amount of emulsifier into the reactor, stir evenly, and raise the temperature to 80-85°C;

[0038] C1: Continuously and evenly add the persulfate solution of the formula amount dropwise, after 3-8 minutes, continuously and evenly add the pre-emulsion obtained in the step A1, dropwise for 2-4 hours, after the dropwise addition, raise the temperature to 87-90°C, keep warm for 1 -2 hours;

[0039] (2), post-processing stage

[0040] A2: Cool down to 70-75°C;

[...

Embodiment 1

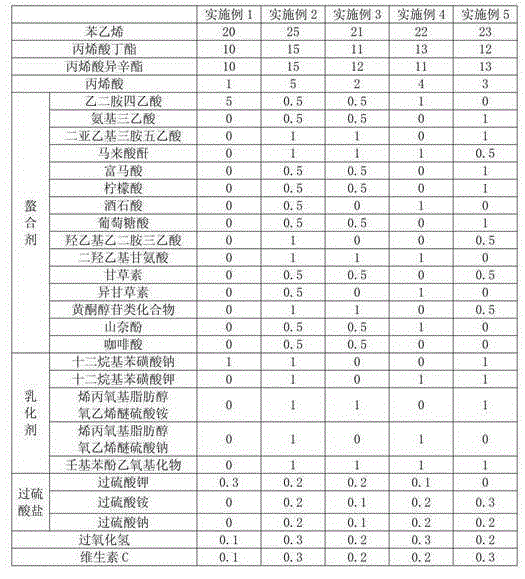

[0048] The water-based styrene-acrylic emulsion of metal chelation of the present invention comprises styrene, butyl acrylate, isooctyl acrylate, acrylic acid, ethylenediaminetetraacetic acid (EDTA), sodium dodecylbenzenesulfonate, potassium persulfate, peroxide Hydrogen, vitamin C and water. The contents of the above components are calculated by mass percentage: styrene 20%, butyl acrylate 10%, isooctyl acrylate 10%, acrylic acid 1%, ethylenediaminetetraacetic acid (EDTA) 5%, dodecylbenzenesulfonate Sodium persulfate 1%, potassium persulfate 0.3%, hydrogen peroxide 0.1-%, vitamin C 0.1%, and the balance is water.

[0049] The water-based styrene-acrylic emulsion preparation method of metal chelation of the present invention comprises the following steps:

[0050] (1), synthesis stage

[0051] A1: Preparation of pre-emulsion, add 35% formula water and 20% formula emulsifier into the pre-emulsification tank, turn on the mixer, and put in the formula styrene, butyl acrylate, i...

Embodiment 2

[0062] The water-based styrene-acrylic emulsion of metal chelation of the present invention comprises styrene, butyl acrylate, isooctyl acrylate, acrylic acid, ethylenediaminetetraacetic acid (EDTA), aminotriacetic acid, diethylenetriaminepentaacetic acid, maleic acid Anhydride, fumaric acid, citric acid (CA), tartaric acid (TA), gluconic acid (GA), hydroxyethylethylenediaminetriacetic acid (HEDTA), dihydroxyethylglycine (DEG), liquiritigenin, isoliquiritigenin , flavonol glycosides, kaempferol, caffeic acid, sodium dodecylbenzenesulfonate, potassium dodecylbenzenesulfonate, allyloxy fatty alcohol oxyethylene ether ammonium sulfate, allyloxy fatty alcohol oxygen Sodium Vinyl Ether Sulfate, Nonylphenol Ethoxylate, Potassium Persulfate, Ammonium Persulfate, Sodium Persulfate, Hydrogen Peroxide, Vitamin C and Water.

[0063] The contents of the above components are calculated by mass percentage: 25% styrene, 15% butyl acrylate, 15% isooctyl acrylate, 5% acrylic acid, 0.5% ethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com