Preparation method of heparin and twin factor synergistically regulated P(LLA-CL)/collagen bilayer intravascular stent

A collagen and vascular stent technology, applied in the directions of blood vessels, stents, anticoagulation treatment, etc., can solve the problems of unfavorable smooth muscle cell growth around the axis, unfavorable three-dimensional osmotic growth of smooth muscle cells, small nano/micro fiber pore size, etc. Promotes periaxial growth and three-dimensional migration, excellent mechanical properties and biocompatibility, and inhibits smooth muscle cell proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

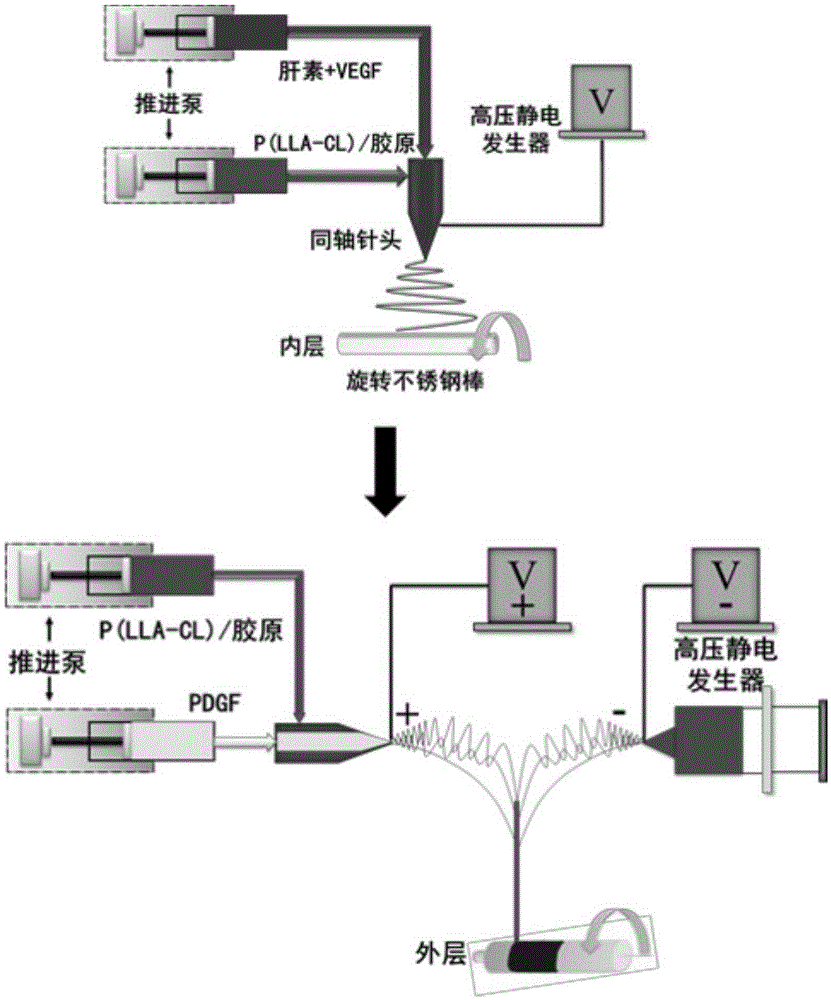

[0039] Weigh 0.9 g of P(LLA-CL) and 0.3 g of collagen with an electronic balance, dissolve them in 10 mL of hexafluoroisopropanol, stir overnight until completely dissolved, and obtain P(LLA-CL) / collagen composite spinning solution; 0.3g heparin sodium and 20 μg VEGF were dissolved in 0.2mL diluent to obtain the drug solution loaded on the inner layer; 20 μg PDGF was dissolved in 0.3mL diluent to obtain the drug solution loaded on the outer layer, wherein the diluent had a pH of 7.2-7.4 PBS buffer solution and 0.1% bovine serum albumin BSA; prepare the inner layer of the blood vessel by coaxial electrospinning, the spinning parameters are as follows: the electrostatic high voltage is 16kV, the shell solution (P(LLA-CL) / collagen Protein composite spinning solution) advancing speed is 1.0mL / h, core layer solution (inner layer loaded drug solution) advancing speed is 0.1mL / h, receiving distance is 12cm, stainless steel rod rotation speed is 1000rpm; spinning is carried out 2 hours...

Embodiment 2

[0041] Weigh 0.75g of P(LLA-CL) and 0.25g of collagen with an electronic balance, dissolve them in 10mL of hexafluoroisopropanol, stir overnight until completely dissolved, and obtain P(LLA-CL) / collagen composite spinning solution; 0.75g heparin sodium and 20 μg VEGF were dissolved in 0.5mL diluent to obtain a drug solution loaded on the inner layer; 20 μg PDGF was dissolved in 0.5mL diluent to obtain a drug solution loaded on the outer layer, wherein the diluent had a pH of 7.2-7.4 PBS buffer and 0.1% bovine serum albumin BSA; prepare the inner layer of the tube by coaxial electrospinning, the spinning parameters are as follows: the electrostatic high voltage is 14kV, the shell solution (P(LLA-CL) / collagen Composite spinning solution) advancing speed is 1.0mL / h, core layer solution (inner layer loaded drug solution) advancing speed is 0.1mL / h, receiving distance is 12cm, stainless steel rod rotation speed is 1200rpm; spinning carries out after 5 hours , using the bidirectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com