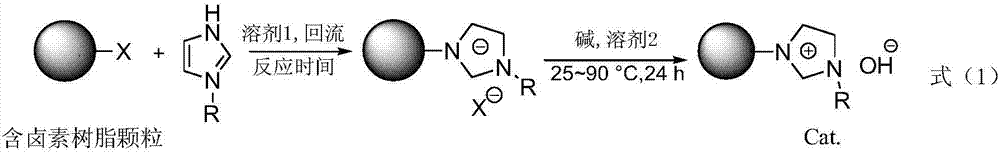

Method for synthesizing dimethyl carbonate and co-producing ethylene glycol through transesterification reaction catalyzed by a loaded ionic liquid

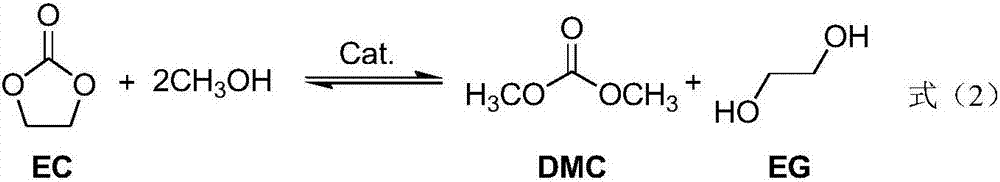

A technology of dimethyl carbonate and ionic liquids, which is applied in the field of catalyzed synthesis of dimethyl carbonate and co-production of ethylene glycol with supported ionic liquids, which can solve problems such as difficult separation of products and catalysts, low catalytic activity, and complicated product purification process , to achieve the effect of promoting the positive movement of the reaction balance, simplifying the separation process, and accelerating the catalytic reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The synthesis of embodiment 1 catalyst

[0022]Add 8.36g of polystyrene resin particles containing 18-19wt% chlorine, two equivalents of methylimidazole and 50mL of toluene to a 100mL three-neck flask equipped with a magnet, and heat to reflux for 24 hours, stop the reaction, and cool to room temperature. After the mixed solution is simply filtered and vacuum-dried, resin particles functionalized with imidazolium cations are obtained. Then, using KOH aqueous solution with a mass percentage of 20%, after ion exchange reaction for 24h, the crude catalyst was obtained, washed with deionized water (3×100mL), ethanol (3×50mL) successively, and dried in vacuo. A supported ionic liquid catalyst chemically modified by the hydroxyl anion structural unit was obtained, and the elements were quantitatively analyzed by an elemental analyzer: the contents of C, H, N, and O were 131.25wt%, 12.29wt%, 25.61wt% and 5.99wt% respectively %, so it is speculated that the loading of hydroxyl...

Embodiment 2

[0023] Embodiment 2 transesterification reaction

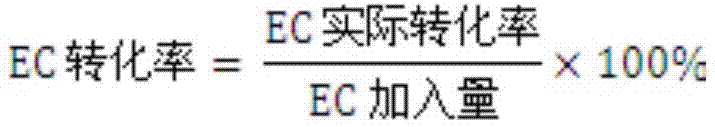

[0024] In the 250mL three-necked round-bottom flask that spherical reflux condenser is housed, add 10g ethylene carbonate, 80g methyl alcohol and the embodiment 1 catalyst that accounts for ethylene carbonate mass percentage composition 8.0wt% successively, after mixing uniformly, insert 80 ℃ in an oil bath, magnetically stirred for 8 hours, cooled to room temperature, and the catalyst was filtered and separated, and the filtrate was quantitatively analyzed by a gas chromatograph, calculated according to Appendix I: the conversion rate of ethylene carbonate reached 99.4%, and dimethyl carbonate was generated. Both ester and glycol selectivities were 99.9%.

Embodiment 3

[0026] In the 250mL three-necked round bottom flask, add 10g ethylene carbonate, 80g methyl alcohol and account for the catalyzer of embodiment 1 of 5.0wt% in ethylene carbonate mass percentage composition successively, other steps are with embodiment 2, and the transformation rate of ethylene carbonate is 68.4%, the selectivity of forming dimethyl carbonate is 73.1%, and the selectivity of ethylene glycol is 99.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com