Hydrogel used for adsorbing heavy metal and preparing method and application thereof

A technology for adsorbing heavy metals and hydrogels, which is applied in the direction of adsorption of water/sewage treatment, chemical instruments and methods, and water pollutants. It can solve the problems of difficult recycling, poor reusability, and low adsorption capacity, and achieve an increase in adsorption capacity. , enhance the mechanical strength, increase the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

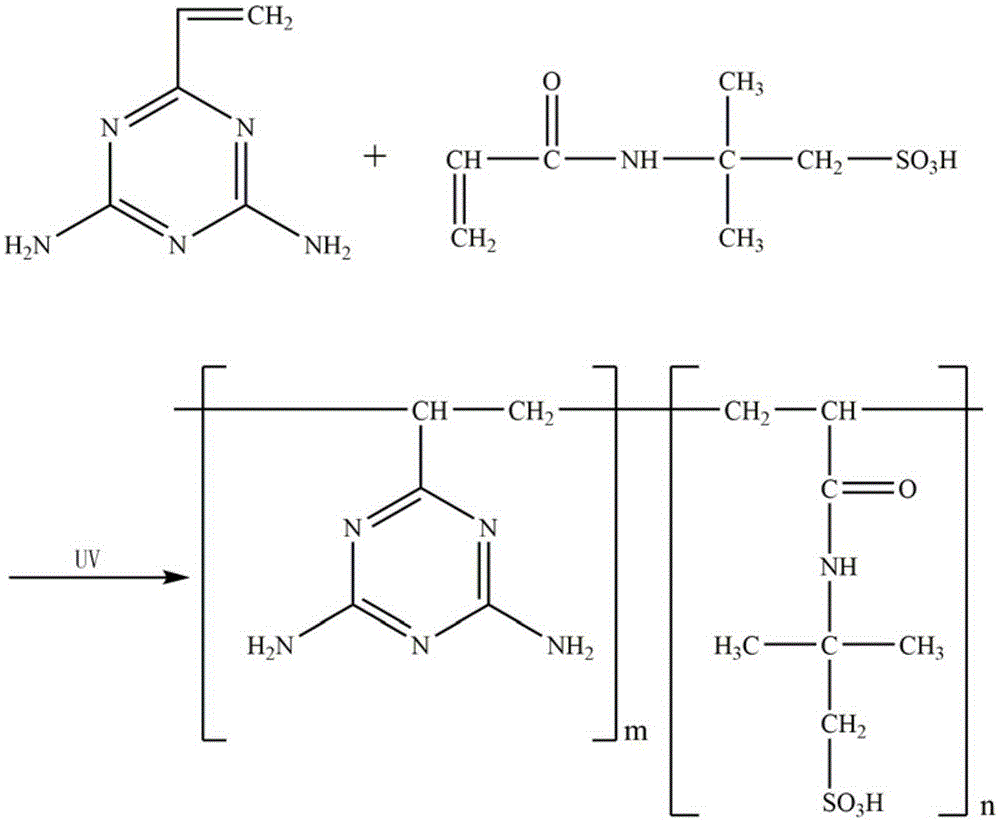

[0035] The preparation method of above-mentioned hydrogel is carried out by following reaction equation:

[0036]

[0037] The specific steps are as follows:

[0038] (1) 2-vinyl-4,6-diamino-1,3,5-s-triazine (VDT) and 2-acrylamide-2-methylpropanesulfonic acid (AMPS) are mixed as reactants, then Add 1% to 10% of the total mass of the reactants and a photoinitiator of 1% to 2.5% of the total mass of the reactants, and dissolve them uniformly in the organic solvent together with the reactants; the crosslinking agent can be N , N-methylenebisacrylamide, polyethylene, polyvinyl chloride, chlorinated polyethylene, etc., the photoinitiator can be 2-hydroxy-4-(2-hydroxyethoxy)-2-methylbenzene Acetone, azobisisobutyl, diphenylethanone, 2,4-dihydroxybenzophenone, etc., the organic solvent can be dimethyl sulfoxide, acetone, methanol, n-hexane, etc.; due to the VDT Amino groups and triazine groups can form a six-membered ring structure through hydrogen bonding. The molar ratio of VD...

Embodiment 1

[0044](1) Weigh 137.15mg VDT (2-vinyl-4,6-diamino-1,3,5-s-triazine), 310.875mgAMPS (2-acrylamide-2-methylpropanesulfonic acid) (VDT and The molar ratio of AMPS is 2:3) as a reactant, and 19.275 mg (5% of the total mass of the reactant) of MBAA (N,N-methylenebisacrylamide) was added to a 5ml centrifuge tube, and the mixture was ultrasonically dissolved In the dimethyl sulfoxide of 3.70ml, obtain mixed solution A; Then in mixed solution A, add photoinitiator 2-hydroxyl-4-(2-hydroxyethoxy)-2-methyl propiophenone 11.21mg ( 2.5% of the total mass of the reactant), sonicated until completely dissolved to obtain the mixed solution B.

[0045] (2) Slowly inject the mixed solution B into the mold, seal it with a rubber silicon tube and clamp it with a clip, and irradiate it under a 20W ultraviolet lamp for 20 minutes to obtain a hydrogel polymer. The reaction equation is as follows figure 1 shown.

[0046] (3) The obtained copolymer hydrogel polymer is taken out from the mold, rinsed...

Embodiment 2

[0048] Repeat Example 1 with the same steps described above, the difference is that the crosslinking agent is polyethylene, the photoinitiator is azobisisobutyl, and the organic solvent is acetone, methanol, and n-hexane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com