a g‑c 3 no 4 /nio photocathode preparation method

A photocathode, g-c3n4 technology, applied in the direction of photovoltaic power generation, photosensitive equipment, electrolytic capacitor manufacturing, etc., to achieve the effect of simple operation, high practical value and application prospect, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a g-C 3 N 4 / NiO / FTO photocathode preparation method, its specific steps are:

[0032] (1) Surface pretreatment of FTO conductive glass

[0033] Soak the FTO conductive glass in absolute ethanol and acetone for two hours, and then heat and reflux in 2mol / L potassium hydroxide isopropanol solution for 30min;

[0034] (2) Preparation of NiO / FTO electrode by hydrothermal method

[0035] Put the FTO glass into 0.25mol / LNi(NO 3 ) 2 ·6H 2 O and 0.25mol / L hexamethylenetetramine in a mixed aqueous solution, heated at 100°C for 12min, taken out, washed with deionized water, dried in the air, and calcined in a muffle furnace at 450°C for 2 hours to obtain NiO / FTO electrode;

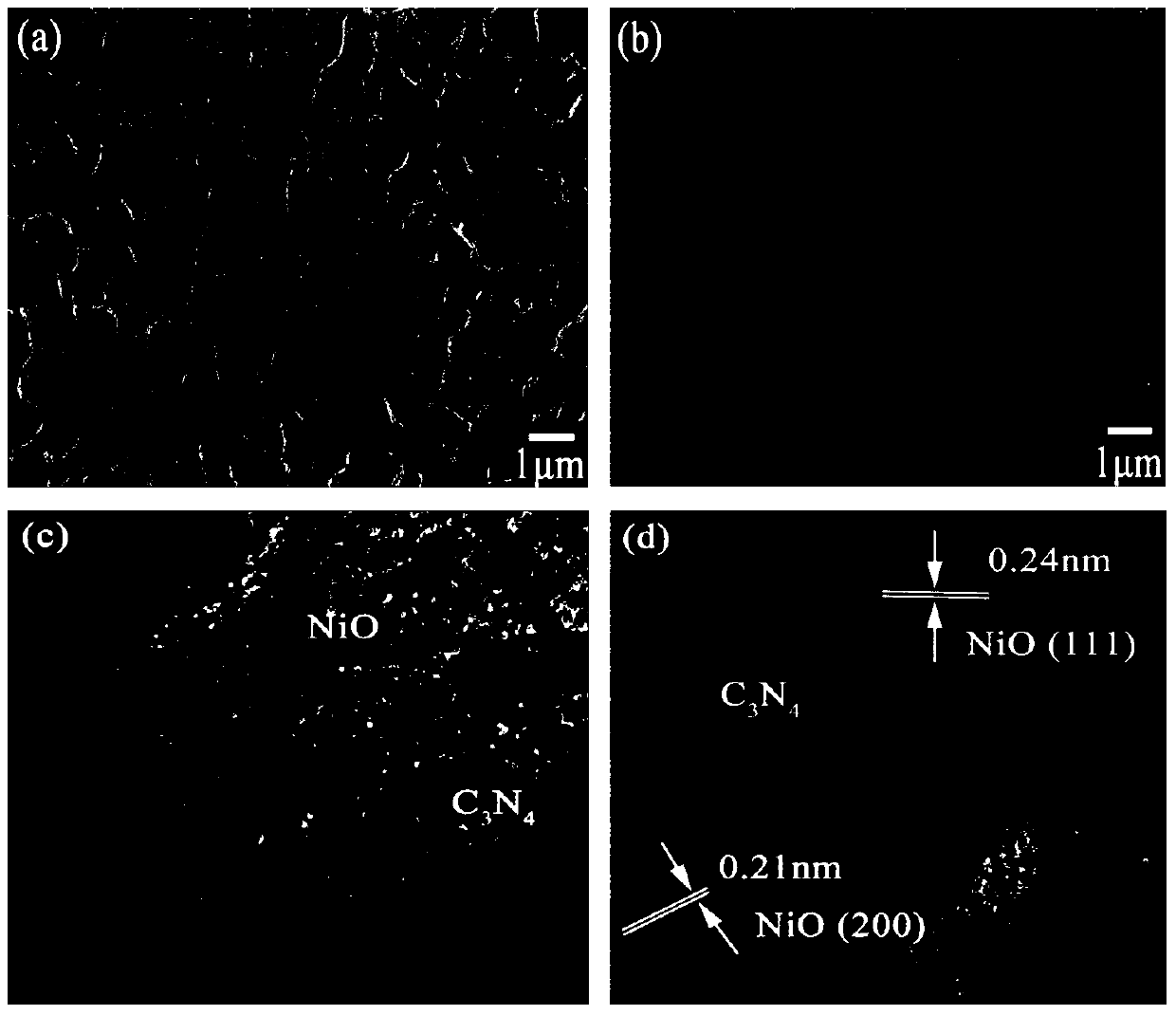

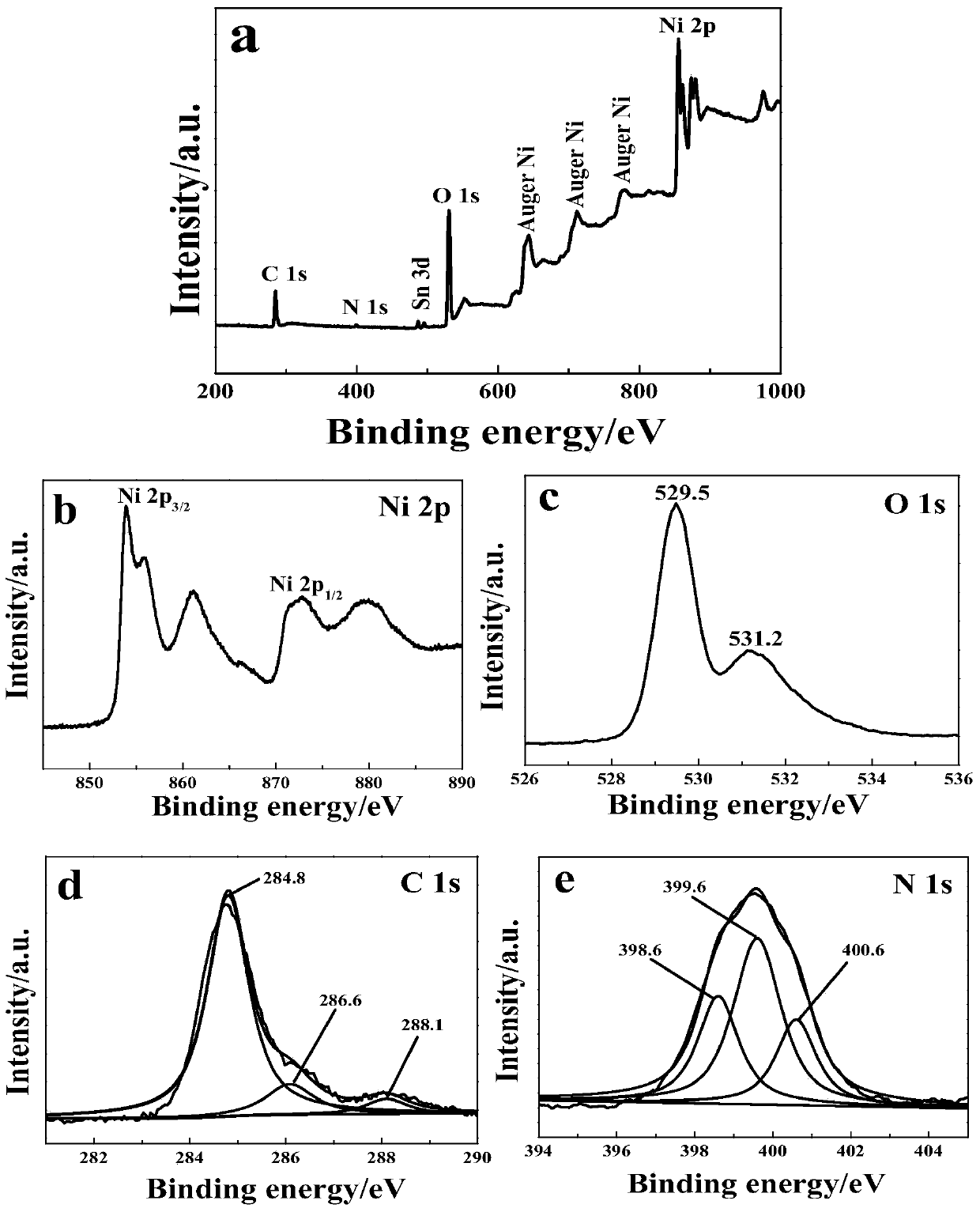

[0036] (3) Prepare g-C by thermal polymerization 3 N 4 Sensitized NiO composite electrode

[0037] Immerse the NiO / FTO electrode prepared above into a saturated thiourea solution for 4 hours, take it out and dry it in the air, and then place the NiO / FTO electrode adsorbed on thiourea in a tube fur...

Embodiment 2

[0040] Examined g-C 3 N 4 / NiO / FTO photocathode photoelectrochemical performance, and under the same conditions with only a single component of g-C 3 N 4 / FTO, NiO / FTO electrodes were compared.

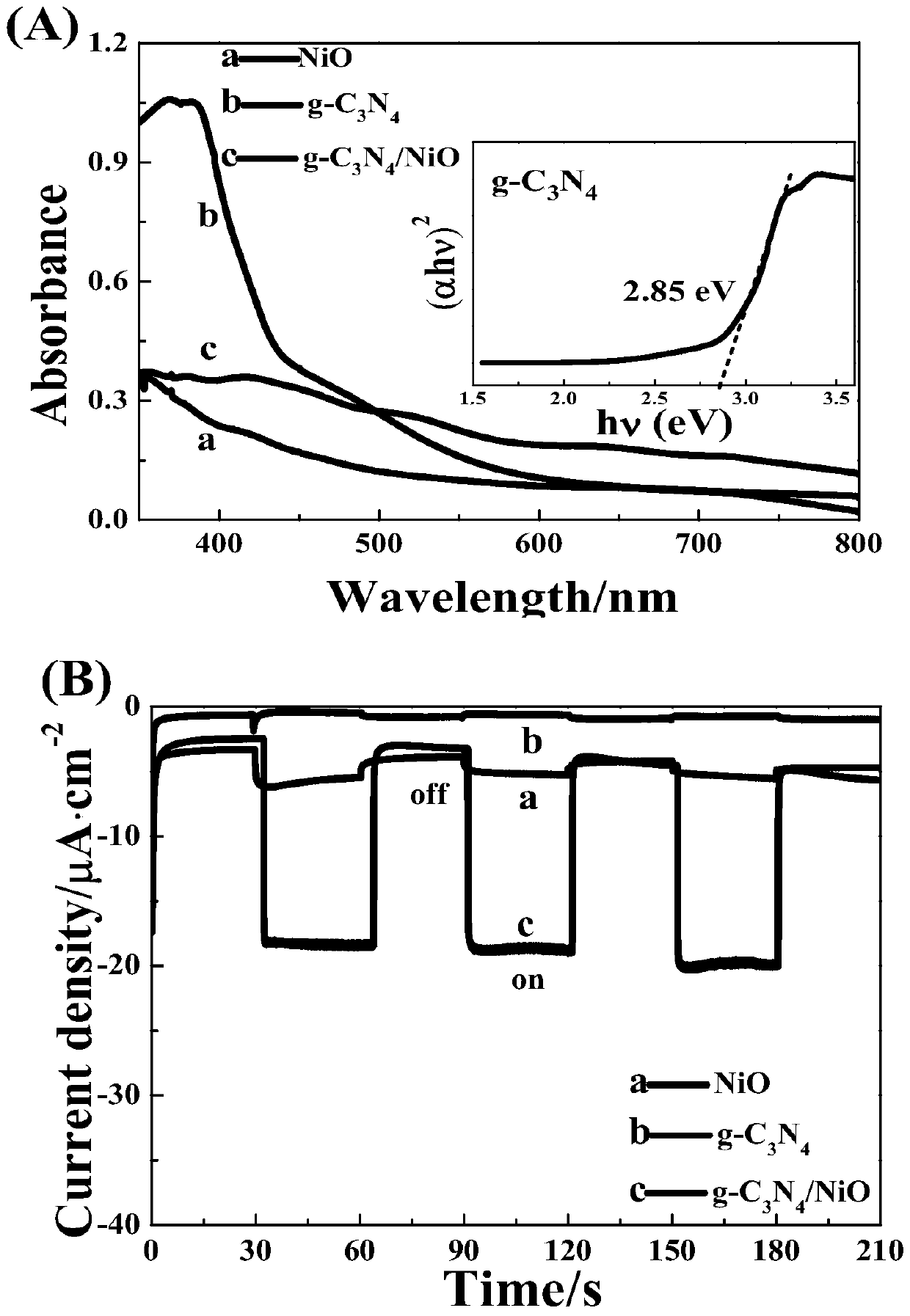

[0041] image 3 (a) is g-C prepared in embodiment 1 3 N 4 / NiO / FTO electrode UV-vis absorption spectrum, as can be seen from the figure, g-C 3 N 4 Its absorption edge is around 440nm, and its forbidden band width can be calculated by the Tork curve in the illustration, and the intersection point of the extension line of the linear part on the corresponding Tork curve and the abscissa is g-C 3 N 4 The forbidden band width value. In addition, it can also be seen from the figure that the absorption of NiO alone in the visible range is very weak, while g-C 3 N 4 / NiO composite electrode shows a strong absorption capacity in the range of 350-460nm. From the above results, it can be seen that: g-C 3 N 4 The absorption peak of the / NiO composite electrode shifts to a longer wav...

Embodiment 3

[0044] The photoelectrochemical stability of an electrode is crucial to a photoelectric hydrogen production system. Therefore, we investigated the prepared electrode g-C 3 N 4 / NiO / FTO long-term stability.

[0045] With 0.10mol / LNa 2 SO 4 As the electrolyte solution, the Ag / AgCl electrode was used as the reference electrode, and the platinum mesh was used as the counter electrode. The prepared g-C 3 N 4 / NiO / FTO electrode as the working electrode, the electrolyte solution was filled with CH 4 / N 2 The mixed gas is degassed to remove the O 2 , and then measured its electrochemical stability with a CHI600E electrochemical instrument.

[0046] Figure 4 (a) and (b) represent g-C respectively 3 N 4 / NiO / FTO electrode using CH 4 / N 2 A plot of current versus time in saturated versus air-saturated electrolyte solutions. It can be seen from the figure that the current of our electrode can maintain long-term stability (10h) under these two conditions. It is worth noting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com