Zinc cobalt oxide/graphene/carbon nanofiber composite material and preparation method thereof

A carbon nanofiber and graphene composite technology, which is applied in the field of cobalt zinc oxide/graphene/carbon nanofiber composite materials and its preparation, can solve the problem of affecting catalytic properties and energy storage cycle stability, and the active sites cannot be fully exposed and other problems, to achieve the effect of ingenious experimental design, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, This embodiment includes the following steps:

[0034] (1) Add 1g of polyacrylonitrile powder to 5mL N,N- Stir continuously in the dimethylformamide solvent to prepare a uniform viscous dispersion;

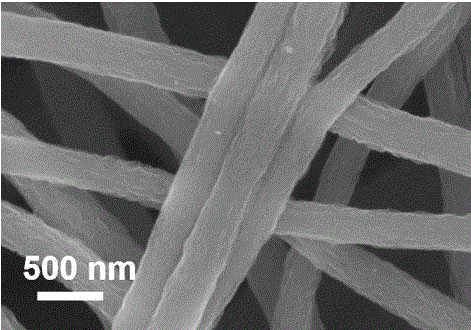

[0035] (2) Electrospin the obtained polyacrylonitrile dispersion, and the adjustment process parameters are: electrostatic field voltage 20kV, spinning speed 0.3mmmin -1 , The receiving distance is 20cm, and the polyacrylonitrile nanofiber membrane is prepared;

[0036] (3) Pre-oxidize the obtained polyacrylonitrile spun membrane in an air atmosphere, the pre-oxidation temperature is 250℃, and the heating rate is 1℃min -1 , The pre-oxidation time is 1.5h, and the pre-oxidized polyacrylonitrile nanofiber membrane is prepared;

[0037] (4) Put the obtained pre-oxidized polyacrylonitrile nanofiber membrane in 1mgmL -1 Soak in graphene oxide solution for 24 hours to prepare polyacrylonitrile nanofiber / graphene oxide composite film;

[0038] (5) The obtained polyacrylonitrile ...

Embodiment 2

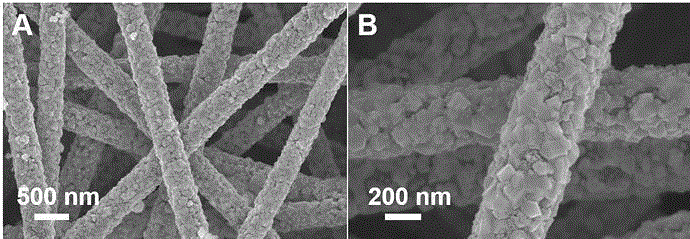

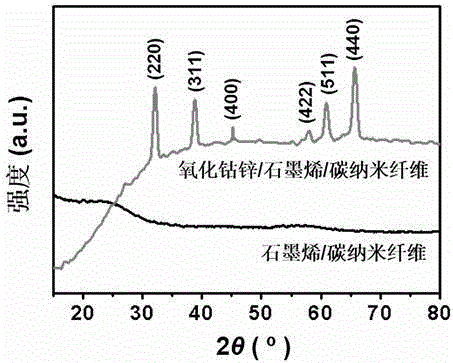

[0041] Example 2, The mass of cobalt nitrate in Example 1 was changed to 290 mg, the mass of zinc nitrate was changed to 145 mg, and the rest were the same as in Example 1. The final composite material obtained was denoted as ZCS / GNS / CNF-2. Implementation results: Cobalt zinc oxide nanoparticles grow uniformly on graphene / carbon nanofibers; compared with ZCS / GNS / CNF-1, the cobalt zinc oxide nanoparticles in ZCS / GNS / CNF-2 have smaller sheets , The content is also less.

Embodiment 3

[0042] Example 3. The mass of cobalt nitrate in Example 1 is changed to 1160mg, the mass of zinc nitrate is changed to 580mg, and the rest are the same as in Example 1. The final composite material obtained is denoted as ZCS / GNS / CNF-2, and the final composite The material is denoted as ZCS / GNS / CNF-3. Implementation results: Cobalt and zinc oxide nanoparticles are uniformly grown on graphene / carbon nanofibers; compared with ZCS / GNS / CNF-1, the layers of cobalt and zinc oxide nanoparticles in ZCS / GNS / CNF-3 are larger , The content is also more.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com