Noise suppression piece and preparation method thereof

A technology of noise suppression sheets and thin sheets, which is applied in metal processing equipment, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of poor absorbing performance, uncontrollable, poor shielding effect, etc., to broaden the absorption frequency band, Meet the requirements of magnetic permeability and shielding, and improve the effect of electromagnetic wave absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A noise suppression sheet, comprising by mass percentage content:

[0034] Flat soft magnetic alloy powder 35wt.%;

[0035] Binder 20wt.%;

[0036] Solvent 44wt.%.

[0037] The flat soft magnetic alloy powder in this embodiment is sendust powder; the binder is water-based polyurethane; the solvent is absolute ethanol.

[0038] The preparation method of the above-mentioned noise suppression sheet comprises the following steps:

[0039] 1) Preparation of flat soft magnetic alloy powder: Take soft magnetic alloy powder, 35wt.% by mass percentage, put it into flattening processing equipment, the speed is 340rpm, and the time is 6 hours; then perform annealing treatment, the specific process is in Under nitrogen protection atmosphere, annealing treatment at 800°C for 1 hour;

[0040] 2) Take the flat soft magnetic alloy powder prepared in step 1), and then add 20wt.% of binder, 45wt.% of solvent, and 1wt.% of organic silicon defoamer in terms of mass percentage content, ...

Embodiment 2

[0047] A noise suppression sheet, comprising by mass percentage content:

[0048] Flat soft magnetic alloy powder 60wt.%;

[0049] Binder 5wt.%;

[0050] Solvent 33wt.%.

[0051] The flat soft magnetic alloy powder in this embodiment is iron-nickel-molybdenum powder; the binder is epoxy resin; the solvent is acetone.

[0052] In order to be more stable, this embodiment also includes coupling agent and dispersant, 1wt.% silane coupling agent, dispersant, 1wt.% oleic acid.

[0053] The preparation method of the above-mentioned noise suppression sheet comprises the following steps:

[0054] 1) Preparation of flat soft magnetic alloy powder: Take soft magnetic alloy powder, 60wt.% by mass percentage, put it into flattening processing equipment, the speed is 380rpm, and the time is 3 hours; then perform annealing treatment, the specific process is in Under nitrogen protection atmosphere, annealing treatment at 800°C for 3 hours;

[0055] 2) Take the flat soft magnetic alloy po...

Embodiment 3

[0062] A noise suppression sheet, comprising by mass percentage content:

[0063] Flat soft magnetic alloy powder 50wt.%;

[0064] Binder 7wt.%;

[0065] Solvent 42wt.%.

[0066] The flat soft magnetic alloy powder in this embodiment is graphite powder; the binder is water-based polyurethane and epoxy resin, and they are mixed at a volume ratio of 1:1.

[0067] The solvent in this example is acetone.

[0068] For stable performance, this embodiment also includes a dispersant, 1wt.% oleic acid.

[0069] The preparation method of the above-mentioned noise suppression sheet comprises the following steps:

[0070] 1) Preparation of flat soft magnetic alloy powder: take soft magnetic alloy powder, 50wt.% by mass percentage, put it into flattening processing equipment, the speed is 350rpm, and the time is 4.5 hours; then annealing treatment is carried out, the specific process is in Under nitrogen protection atmosphere, annealing treatment at 800°C for 2 hours;

[0071] 2) Tak...

PUM

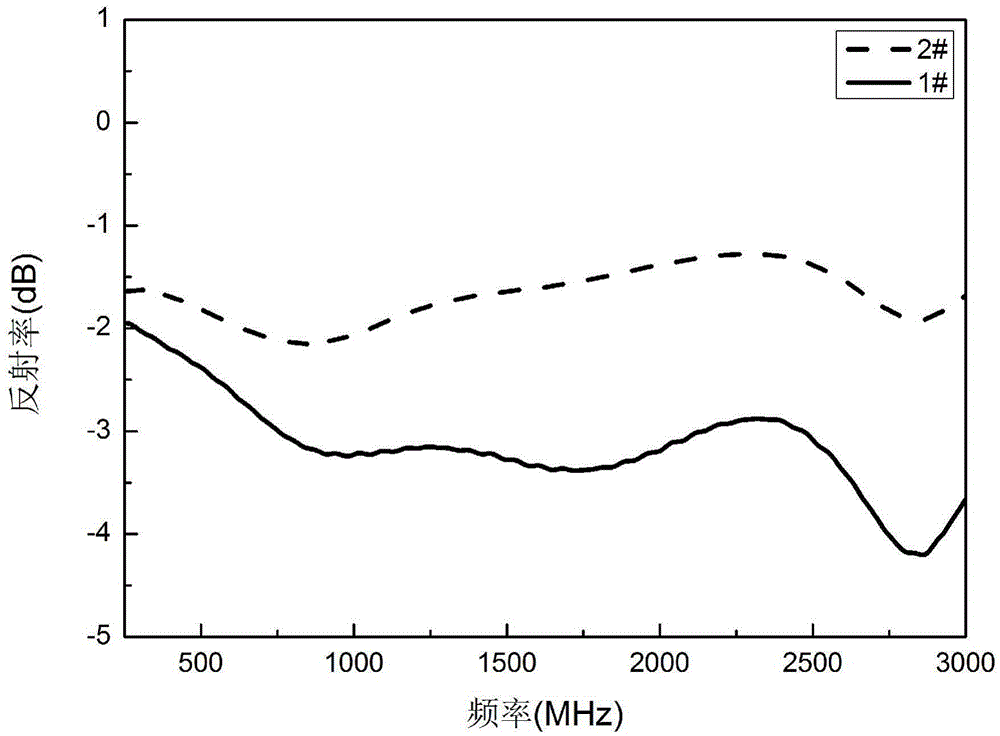

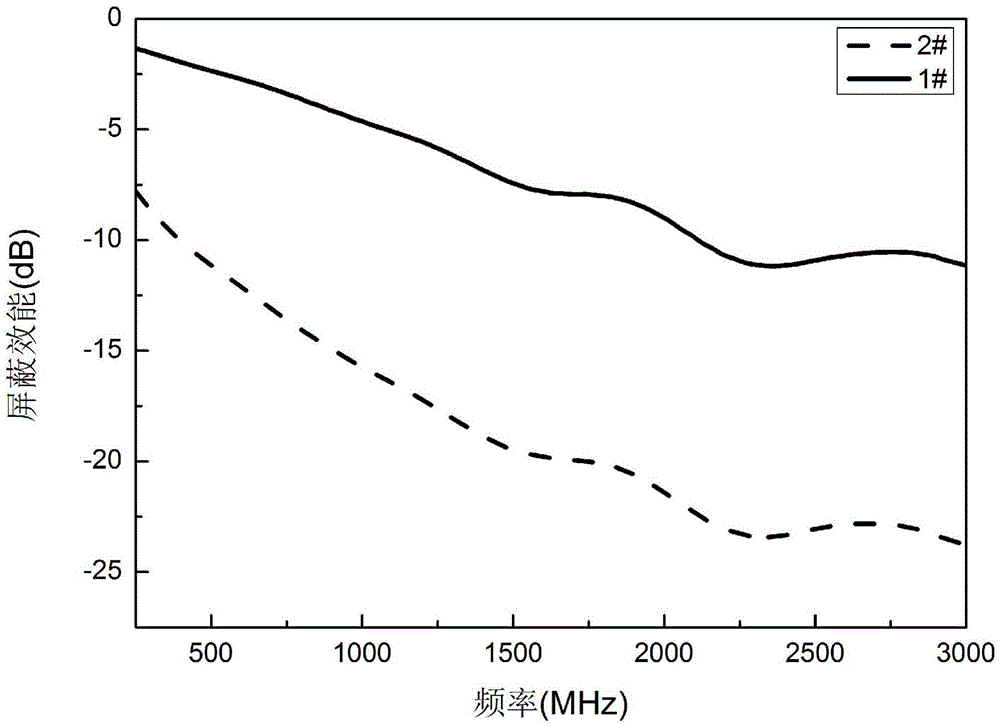

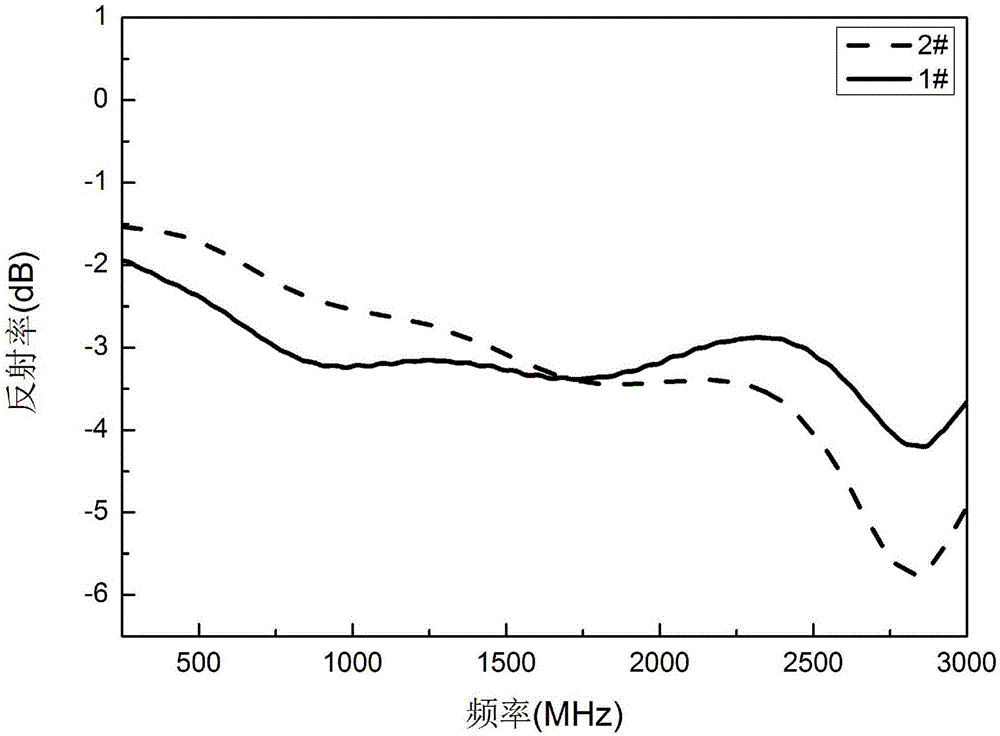

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com