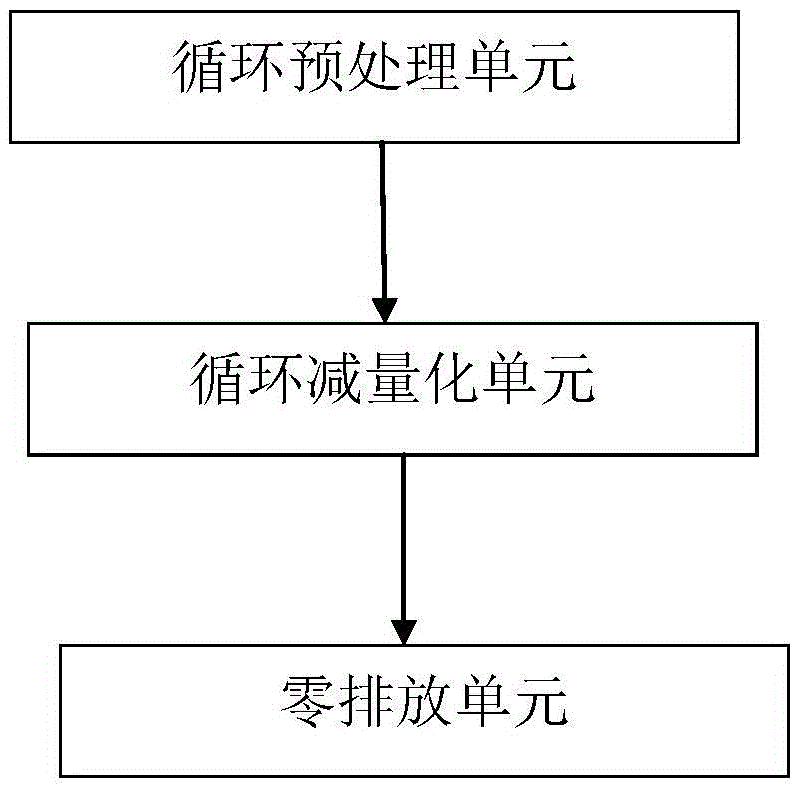

Zero discharge treatment system of high salt wastewater

A treatment system, zero-discharge technology, applied in multi-stage water treatment, water/sewage treatment, heated water/sewage treatment, etc., can solve the problems of large steam consumption, high treatment cost, high investment cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

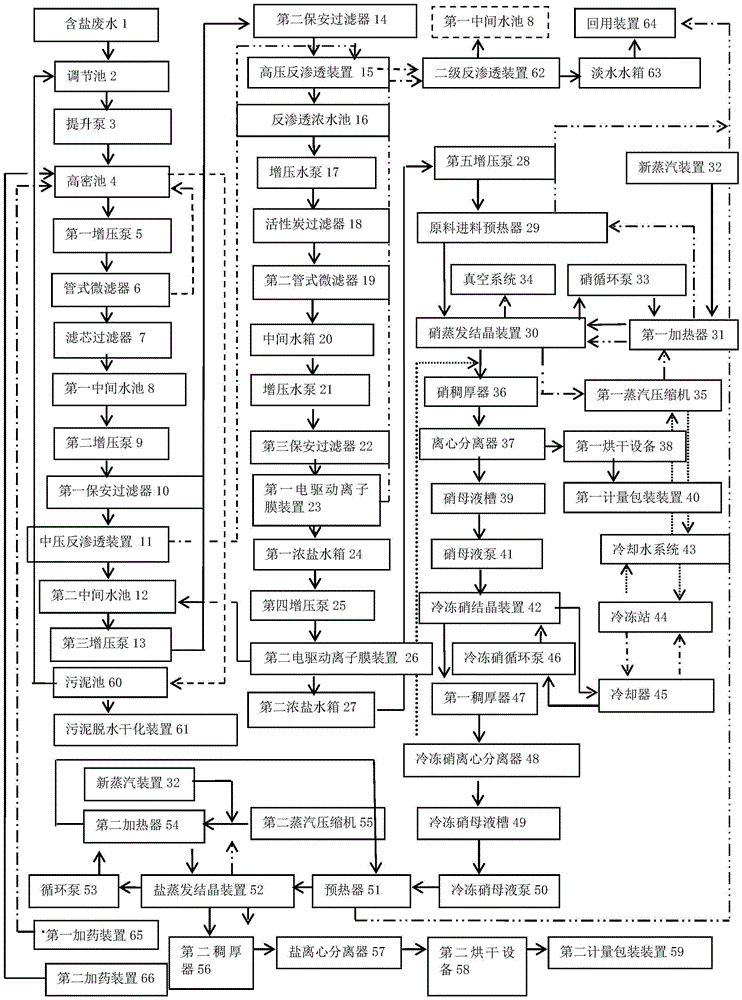

[0097] Such as figure 2 The schematic diagram of the process flow is shown. This integrated process is used to treat industrial salty wastewater with complex components. The wastewater comes from industrial sewage treatment and reuse of reclaimed water drainage, sewage from circulating water system, production process drainage, desalinated water station and secondary reverse osmosis concentrated water and backwash water etc.

[0098] Firstly, the wastewater 1 sent from various channels is adjusted in homogeneity and quantity through the adjustment tank 2 . The raw water is sent to the high-density pool 4 through the lift pump 3 . Here, the first dosing device 65 and the second dosing device 66 sequentially add lime or sodium hydroxide, sodium carbonate, PAC, and PAM. Sodium hydroxide is prepared into a solution of 20% concentration, and the dosage is 1.5g / L, and it is prepared into a 15% concentration of sodium carbonate solution. The dosage is 3g / L raw water concentration...

Embodiment 2

[0106] This embodiment is an improved embodiment of the first embodiment, and is a preferred implementation mode of the present invention. This embodiment only describes system parts that are different from those in Embodiment 1, and the same system parts are not described again.

[0107] An electrocoagulation device is connected between the regulating pool 2 and the high-density pool 4 . Electrocoagulation device consisting of a cylindrical acrylic housing and metal electrodes. Six medium-carbon steel electrodes with a size of 110mm×90mm×2mm were used as anodes, and six stainless steel (SS316) electrodes with a size of 110mm×90mm×1mm were used as cathodes in the electrocoagulation device. The anode and cathode electrodes were assembled in an alternating sequence with a 6mm gap between electrodes. A DC power supply was used to apply DC current to the electrocoagulation device. The DC current was varied from 1.5 amps to 3.5 amps with a dwell time of 30 minutes. Saline waste...

Embodiment 3

[0111] The present invention is an embodiment improved on the basis of the first embodiment and / or the third embodiment. This embodiment only describes system parts that are different from those in Embodiment 1 and Embodiment 2, and the same system parts are not repeated here.

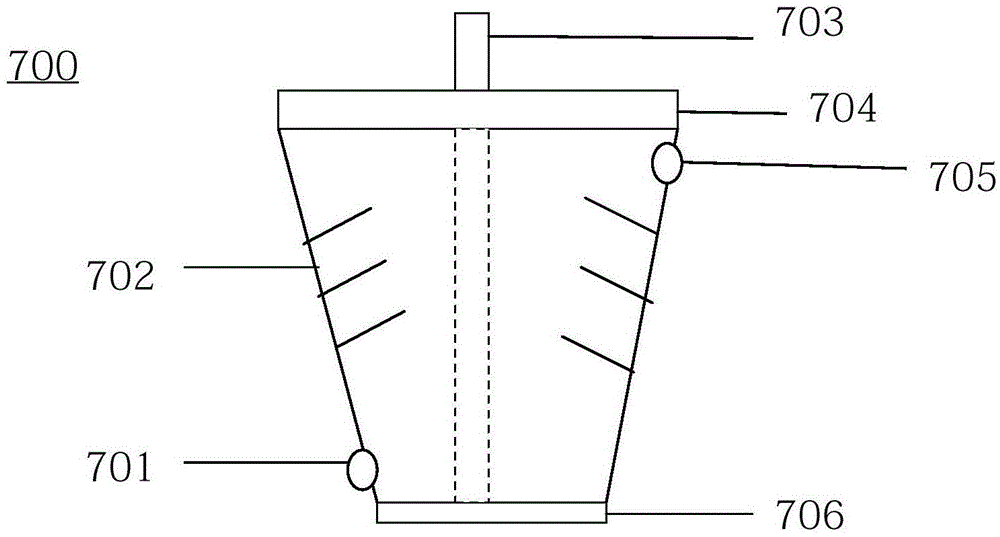

[0112] Both the first electrically driven ionic membrane device 23 and the second electrically driven ionic membrane device 26 of the present invention include an anode and a cathode arranged at intervals. There is a filled chamber between the anode and cathode. The filling chamber is insulated from the anode and the cathode, respectively, by a diaphragm. The material of anode and cathode is activated carbon fiber. The diaphragm is an ion exchange membrane or an insulating porous diaphragm. The filling chamber is filled with a plurality of activated carbon particles, carbon fibers or carbon nanotubes with particle diameters ranging from 0.1 to 5.0 mm. Preferably, the filling chamber is filled with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com