Nickel-cobalt alloy/polypyrrole/reduced graphene nanometer composite material and application thereof

A nanocomposite material, nickel-cobalt alloy technology, applied in the field of electrochemistry, can solve the problem of low water solubility, and achieve the effect of low cost, easy operation, and simple electrode preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

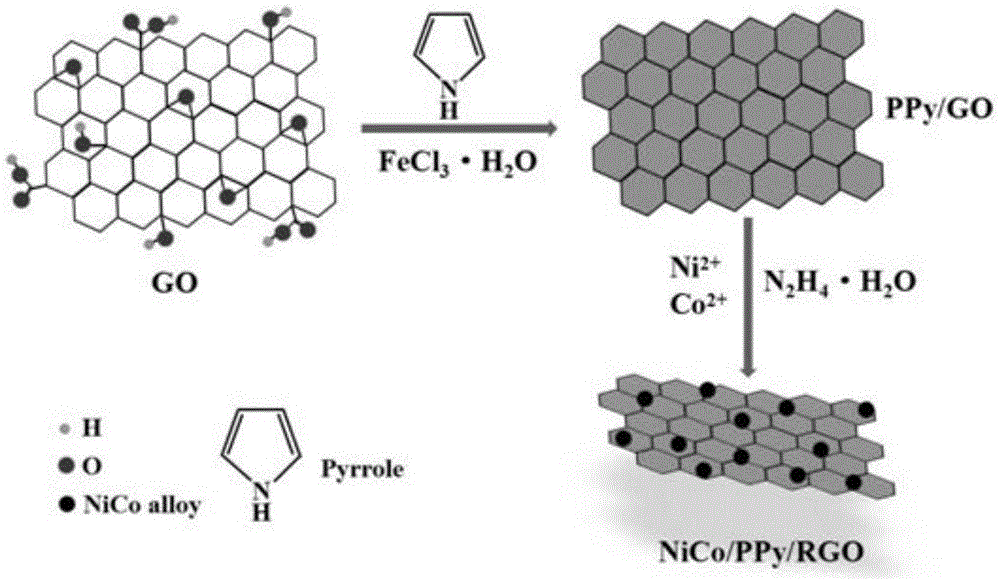

[0037] First, weigh 0.05 g of graphite oxide and ultrasonically disperse it in water to form 2 mg·mL -1 of aqueous solution. Then suck 25 μL of pyrrole monomer and slowly add it into the above aqueous solution for sonication. After 40 min, 10 mL containing 0.3022 g of ferric chloride was added dropwise into the mixture and continued to sonicate for 0.5 h. The polypyrrole / graphene composite was obtained by washing and drying for the next step of preparation.

[0038] First, 12.5 mg of polypyrrole / graphene composite was ultrasonically dispersed in 38 mL of ethylene glycol solution. After 30 min, 18.72 mg of nickel chloride and 6.34 mg of cobalt chloride were added to continue ultrasonication to make it uniform. Pass N before heating in water bath 2 Oxygen was removed, then the temperature was gradually raised to 100°C, and hydrazine hydrate was added dropwise to reduce the nickel-cobalt particles. After continuing to react and reflux for 1 hour, cool naturally, wash and dry ...

Embodiment 2

[0042] First, weigh 0.05 g of graphite oxide and ultrasonically disperse it in water to form 2 mg·mL -1of aqueous solution. Then draw 50 μL of pyrrole monomer and slowly add it into the above aqueous solution for sonication. After 40 minutes, 10 mL containing 0.6044 g of ferric chloride was added dropwise to the mixture and continued to be ultrasonicated for 0.5 h. After washing and drying, the polypyrrole / graphene composite was obtained for the next step of preparation.

[0043] First, 12.5 mg of polypyrrole / graphene composite was ultrasonically dispersed in 38 mL of ethylene glycol solution. After 30 minutes, 17.06 mg of nickel chloride and 8.54 mg of cobalt chloride were added to continue ultrasonication to make it uniform. Pass N before heating in water bath 2 Oxygen was removed, then the temperature was gradually raised to 110°C, and hydrazine hydrate was added dropwise to reduce the nickel-cobalt particles. After continuing to react and reflux for 1 hour, cool natural...

Embodiment 3

[0046] In the specific measurement, the glassy carbon electrode modified by the nickel-cobalt alloy / polypyrrole / reduced graphene nanocomposite prepared in Example 1 was used as the working electrode, the saturated calomel electrode was used as the reference electrode, and the platinum electrode was used as the auxiliary electrode. The electrolyte is 10mL of 0.1mol / L NaOH solution.

[0047] According to the preparation method of Example 1, the polypyrrole / reduced graphene nanocomposite material and the nickel-cobalt alloy nanocomposite material were prepared respectively. The composite material and the nickel-cobalt alloy nanocomposite material were respectively coated on the glassy carbon electrode, and the catalytic performance of each modified electrode on glucose was tested.

[0048] Such as Figure 5 As shown in the cyclic voltammogram, compared to polypyrrole / reduced graphene nanocomposite (curve a), nickel-cobalt alloy nanocomposite (curve b), nickel-cobalt alloy / polypy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com