A kind of preparation method of mixed borosiloxane

A technology of borosiloxane and mixed ring, which is applied in the field of preparation of mixed borosiloxane, which can solve the problems of inapplicability and easy hydrolysis, and achieve the effect of low price, low cost and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

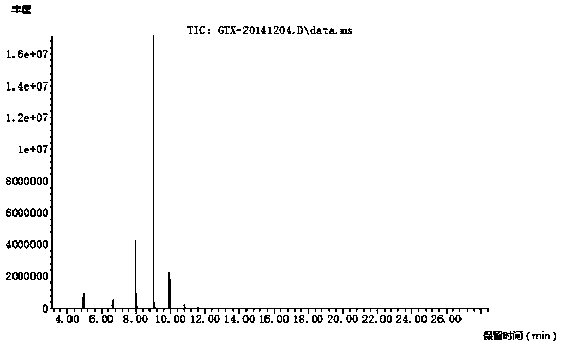

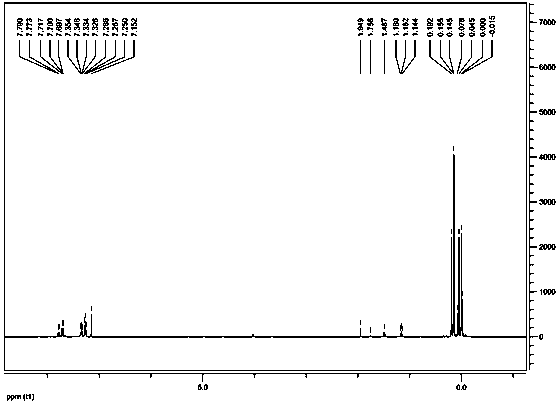

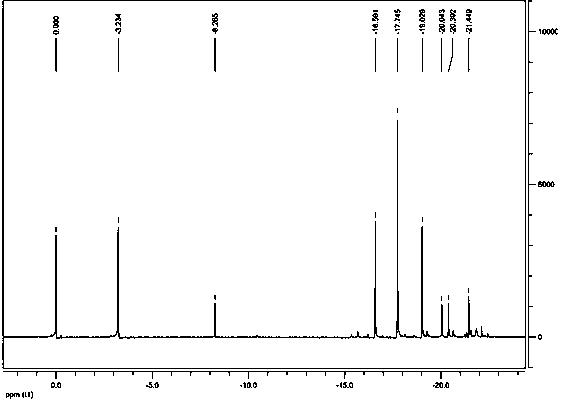

Image

Examples

Embodiment 1

[0033] The three-necked reaction flask is equipped with electromagnetic stirring, a constant pressure dropping funnel, and a three-way valve. Under the protection of nitrogen at 20°C, dissolve 0.03mol of phenylboronic acid in 50ml of tetrahydrofuran, put it into the constant pressure dropping funnel, and put it in the three-necked reaction flask. Add 0.15mol dimethyldichlorosilane, drop phenylboronic acid within 30 minutes, continue to react for 5h after the dropwise addition, and then add 0.3mol zinc oxide and 500ml ethyl acetate into the reaction flask under the protection of nitrogen Stir to form a suspension, then transfer the solution after the reaction in the previous step to a constant pressure dropping funnel, drop it into the suspension within 30 minutes, and continue to react for 12 hours after the addition; filter out the insoluble zinc salt, and wash the filtrate with water 100ml After ×2 times, wash 100ml with distilled water ×2 times; dry with anhydrous sodium sul...

Embodiment 2

[0040] The three-neck reaction flask is equipped with electromagnetic stirring, a constant pressure dropping funnel, and a three-way valve. Under the protection of nitrogen at 50°C, dissolve 0.05mol methyl boric acid in 50ml of toluene, put it into the constant pressure dropping funnel, and put it in the three-necked reaction flask. Put in 0.4mol diethyldichlorosilane, add methyl boric acid dropwise within 20 minutes, and continue the reaction for 4 hours after the dropwise addition. Then under the protection of nitrogen, at -10 ° C, first add 0.4 mol of calcium oxide and 500 ml of methyl acetate into the reaction flask and stir to form a suspension, and then transfer the solution after the previous step to the constant pressure dropping funnel. Add it dropwise to the suspension within 20 minutes, and continue to react for 18 hours after the addition; filter off the insoluble calcium salt, wash the filtrate 100ml×2 times with distilled water, and then wash 100ml×2 times with di...

Embodiment 3

[0048] The three-neck reaction flask is equipped with electromagnetic stirring, constant pressure dropping funnel, three-way valve, and electric heating mantle. Under the protection of nitrogen at -20°C, dissolve 0.03mol of phenylboronic acid in 50ml of dichloromethane and put it into the constant pressure dropping funnel. , put 0.09mol diethyldichlorosilane into the three-neck reaction flask, add phenylboronic acid dropwise within 40 minutes, and continue the reaction for 8 hours after the dropwise addition. Then, under the protection of nitrogen at 50°C, first add 0.2mol of copper oxide and 500ml of n-hexane into the reaction flask and stir to form a suspension, then transfer the solution after the reaction in the previous step to a constant pressure dropping funnel, and drop it within 40 minutes. into the suspension, continue to react for 8 hours after the addition; filter off the unreacted copper salt, wash the filtrate 100ml x 2 times with distilled water, then wash 100ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com