Cyanobacteria aliphatic hydrocarbon key synthesis gene and application thereof

A cyanobacteria, hydrocarbon gene technology, applied in the application, bacteria, genetic engineering and other directions, can solve the problem of not reaching industrial application, and achieve the effect of increasing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] Embodiment 1: the cultivation and biomass determination of cyanobacteria

[0105] Cultivation and physiological index determination of cyanobacteria:

[0106] The cyanobacterial strains in Table 1 were cultured by aeration culture, and the algae strains were inoculated into a 500mL Erlenmeyer flask containing 300mL of BG11 medium, at 30°C, 30μE.m -2 .s -1 Grow in continuous light for 8 to 10 days. In order to measure its growth, 10ml of the well-mixed cyanobacteria suspension was passed through a 0.45μm pre-weighed nitrocellulose membrane (ddH 2 O washed three times, 110 ℃ high temperature drying) after suction filtration, put 110 ℃, dry 24 hours, and weigh its dry weight. Finally, the dry weight of the bacteria was used as a reference index to measure the biomass. The strains and their sources are listed in Table 1.

[0107] Algae (bacteria) strains used in Table 1 and their sources

[0108]

[0109] a FACHB: FreshwaterAlgalCultureCollectionofTheInstituteOfHy...

Embodiment 2

[0111] Embodiment 2: the aliphatic hydrocarbon composition and content determination of cyanobacteria

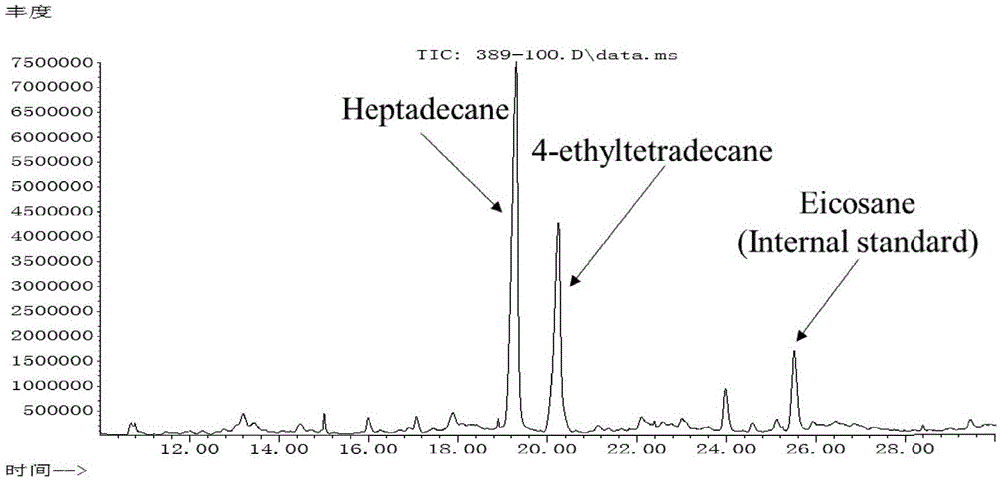

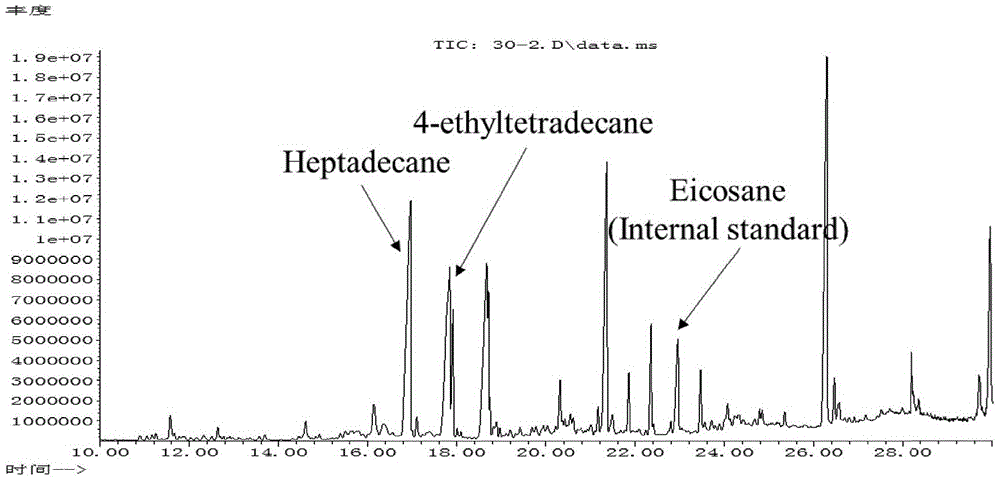

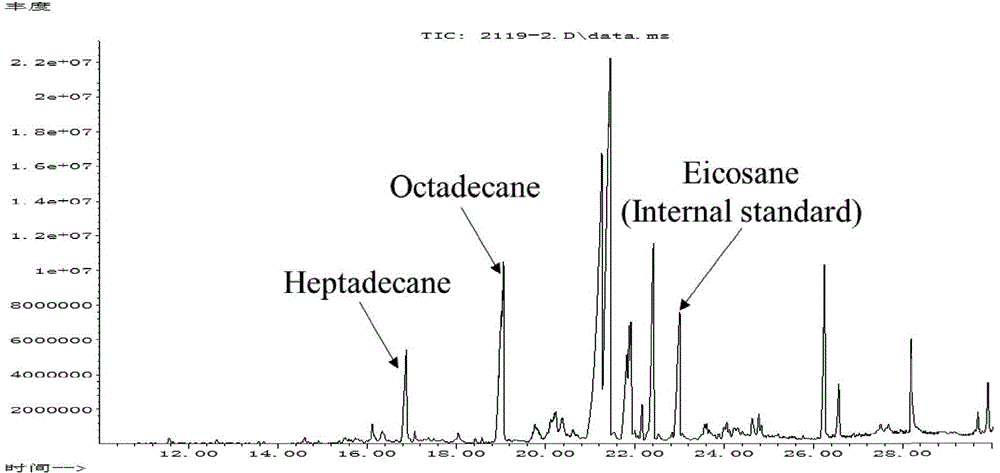

[0112] Each of the above-mentioned 200mL of cyanobacteria (in Table 1) that was in the plateau phase and well mixed was collected, and mixed with 10mLddH 2 O resuspended the above-mentioned cyanobacteria respectively, and then placed them on an ice-water bath, and ultrasonically disrupted them for 10 minutes (10son, 10soff). After crushing, add 30 μg of n-eicosane as an internal standard, and after mixing, add 10 mL of chloroform:methanol (V:V is 2:1), shake and mix vigorously for 1-2 hours. Then centrifuge at 6,000 g for 10 min, transfer the lower organic phase to a new test tube, and dry it with nitrogen at 55°C. Add 1ml of n-hexane to dissolve the extracted aliphatic hydrocarbons, then filter through a 0.22μm membrane filter, and transfer to a 2ml gas phase vial. Use Agilent7890A gas chromatography-mass spectrometry (GC-MS) to measure aliphatic hydrocarbons. The GC-MS t...

Embodiment 3

[0119] Example 3: Sequencing of the cyanobacteria genome and sequence retrieval of the key gene ado-aar for hydrocarbon production

[0120] (1) The extraction steps of the cyanobacteria genome are as follows:

[0121] Collect about 50ml of each bacterial solution that is fully mixed, centrifuge at 5,000g, and use 1.8ml of solution A (50mM Tris-Cl+50mMNa 2 EDTA+1MNaCl), and then moderately homogenized with a 2ml tissue homogenizer to disperse the filamentous cell homogenate into a single cell state.

[0122] Then proceed as follows: the cell suspension of each of the above-mentioned cyanobacteria and algal strains is divided into 6 Eppendorf tubes (300 μl / tube), and 10% sodium lauryl sarcosine aqueous solution (Sarkosyl solution) is added to each tube. The final concentration is 0.1%, and then stored at 4°C for 1 hr, centrifuged at 10,000g for 15 min to pellet the cells; wash the cells twice with 1ml solution A;

[0123] After washing, resuspend the cyanobacteria and algae ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com