Preparation method of inorganic ion exchange material for stationary phase in solid phase extraction

An inorganic ion exchange and stationary phase technology, applied in separation methods, inorganic chemistry, chemical instruments and methods, etc., can solve problems such as limited production conditions for large-scale use, poor mechanical strength and hydraulic properties, and inability to meet industrial applications. , to achieve the effect of good hydraulic performance and mechanical strength, high extraction capacity and partition coefficient, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

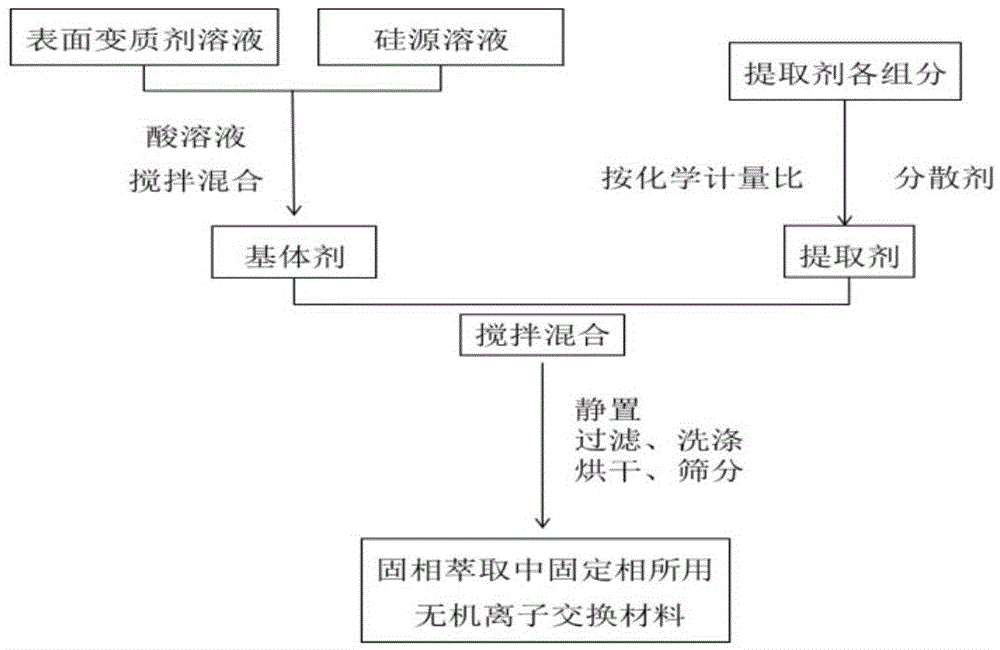

[0018] Embodiment 1: a kind of preparation method of inorganic ion exchange material used for stationary phase in solid phase extraction, comprises the following steps:

[0019] A. Synthesis of matrix agent: use ethanol as solvent, add tetraethyl orthosilicate and polyvinyl alcohol 1788 accounting for 2-5% of water solvent mass percentage according to a certain volume ratio, the mass ratio is about 10:7.2:10g, Under normal temperature and pressure conditions, stir evenly, at 5-7mol L -1 Hydrochloric acid (volume: 0.1 ~ 0.4mL) solution to react, the reaction time is until the solution system is transparent, so that they are mixed together;

[0020] B, the synthesis of extractant: in water solvent, add potassium pyrophosphate (K 4 P 2 o 7 2H 2 O), sodium molybdate (Na 2 MoO 4 2H 2 O), zirconium oxychloride (ZrOCl 2 ·8H 2 O), where Na 2 MoO 4 2H 2 O use 0.93g, use 4 ~ 7mol L -1 Nitric acid (volume: 0.3 ~ 0.8mL) solution was acidified, mixed evenly, a chemical reactio...

Embodiment 2

[0024] Embodiment 2: a kind of preparation method of inorganic ion exchange material used for stationary phase in solid phase extraction, comprises the following steps:

[0025] A. Synthesis of matrix agent: use water as solvent, add silica gel and polyethylene glycol 400 with a mass percentage of 3-5% of water solvent according to a certain volume ratio, the mass ratio is about 10:8:10g, normal temperature and pressure Stir evenly under the condition of 5~7mol L -1 Hydrochloric acid (volume: 0.1 ~ 0.4mL) solution to react, the reaction time is until the solution system is transparent, so that they are mixed together;

[0026] B. Synthesis of extractant: accurately weigh zirconium oxychloride (ZrOCl) according to the stoichiometric ratio 2 ·8H 2 O) 1.61g in a beaker, then add 5mL of water to ZrOCl 2 ·8H 2 O dissolves completely. Immediately, pipette gun to pipette 85% phosphoric acid (volume: 0.5mL), slowly add it dropwise into the beaker, keep stirring at room temperatur...

Embodiment 3

[0030] Embodiment 3: a kind of preparation method of inorganic ion exchange material used for stationary phase in solid phase extraction, comprises the following steps:

[0031] A. Synthesis of matrix agent: take methanol as solvent, add tetraethyl orthosilicate and polyethylene glycol 2000 accounting for 3-5% by mass of water solvent in a certain volume ratio, and the mass ratio is about 10:10:10g , under the condition of normal temperature and pressure, stir evenly, in nitric acid 5 ~ 8mol L -1 Nitric acid (volume: 0.1 ~ 0.4mL) solution to react, the reaction time is until the solution system is transparent, so that they are mixed together;

[0032] B. Synthesis of extractant: Accurately weigh ferric chloride (FeCl 3 ) and potassium ferrocyanide (K 4 [Fe(CN) 6 ]) in a beaker, in which 0.46gFeCl 3 , and then add 10mL of water to dissolve it completely, then add it to the reaction vessel, stir continuously at normal temperature and pressure for 1h to fully react, and gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com