Reduction treatment method for high-salt wastewater

A treatment method and reduction technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve the waste of water resources, low recycling rate of wastewater and water resources, and difficult disposal of reverse osmosis concentrated water. It can improve the water production rate, avoid the pollution of calcium and magnesium ions, and avoid the scaling problem of heavy metal ions on the membrane surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

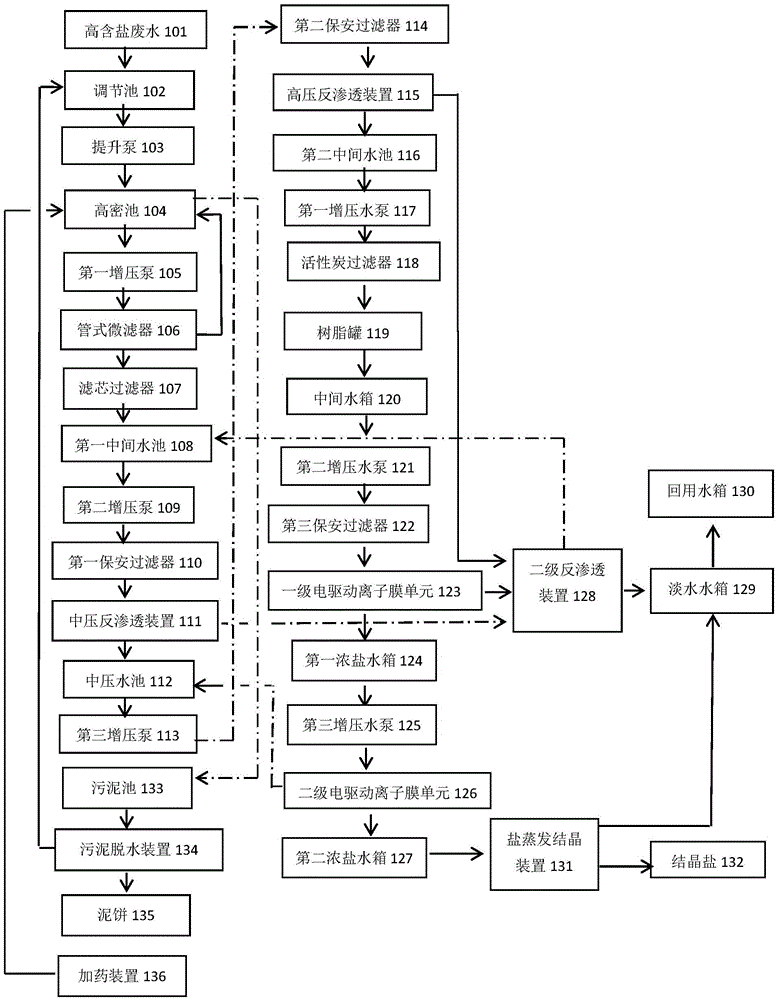

[0064] combine figure 1 The wastewater pretreatment process of the present invention will be described. The high-salt wastewater 101 is subjected to homogeneous and even quantity regulating treatment through the regulating tank 102 . The high-salt wastewater 101 comes from the sewage of the circulating water system in the industrial sewage treatment and the sewage of the production process. The regulated and treated wastewater is sent to the high-density pool 104 through the lift pump 103 . Add lime or sodium hydroxide, sodium carbonate, polyaluminum chloride, and polyacrylamide to the high-density pool 104 sequentially through the dosing device 136, and adjust the wastewater to an alkaline environment. The added sodium hydroxide and sodium carbonate are used for softening waste water, sodium hydroxide is mixed with a solution of 20% concentration, and the dosage is 1.5g / L, and sodium carbonate is mixed with a solution of 15% concentration, and the dosage is 3g / L, the added...

Embodiment 2

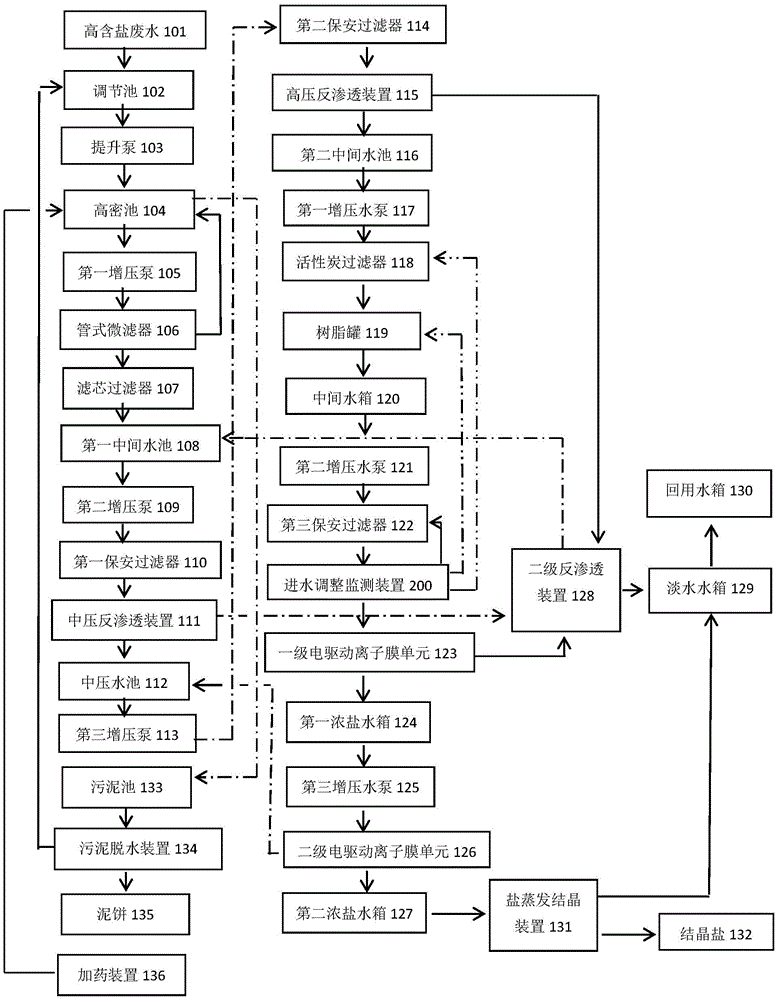

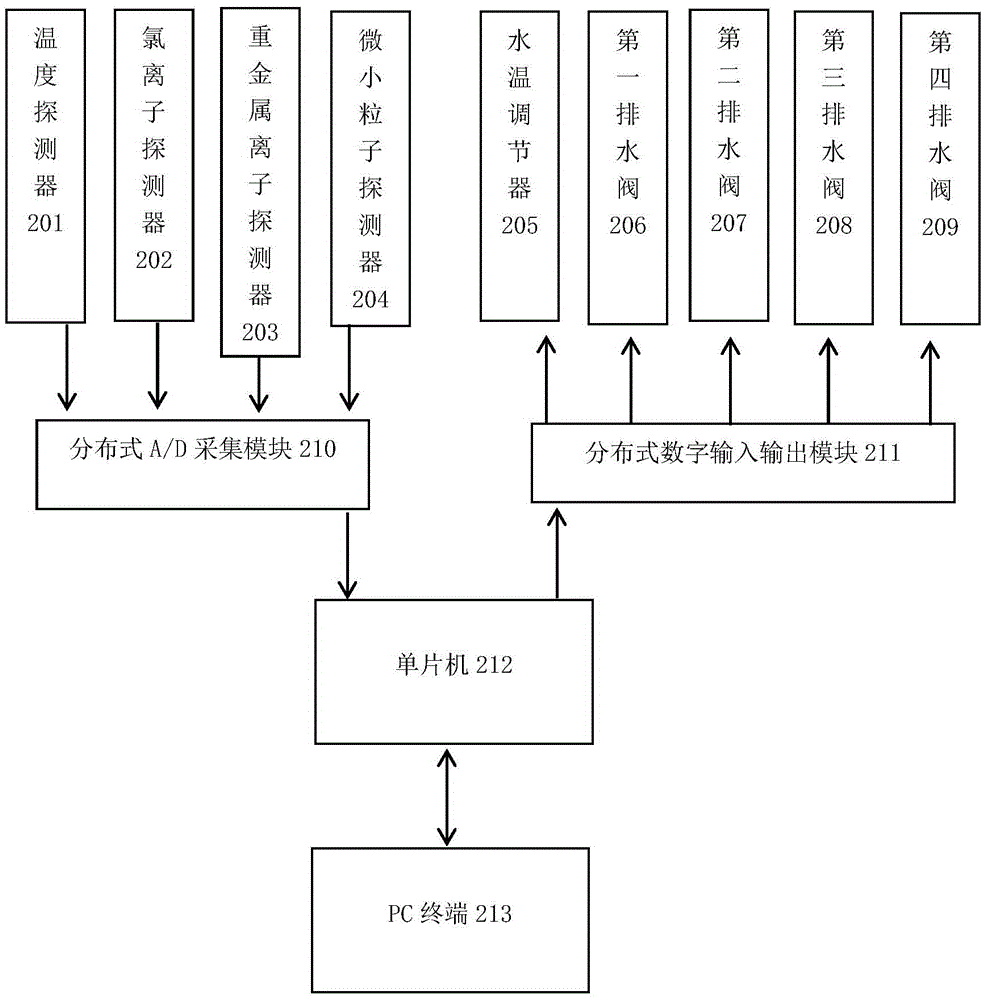

[0066] combine figure 2 and image 3 The wastewater reduction treatment process of the present invention will be described. In order to realize the recycling and reuse of wastewater, the wastewater reduction process includes the preliminary reduction treatment of wastewater and the deep concentration treatment process of wastewater.

[0067] The second booster pump 109 transports the pretreated wastewater in the first intermediate pool 108 to the first security filter 110 . The first security filter 110 is used to filter out tiny suspended matter in the wastewater, and the filtered wastewater is sent to the medium-pressure reverse osmosis device 111 .

[0068] According to a preferred embodiment, the medium-pressure reverse osmosis device 111 uses a medium-pressure membrane element whose membrane material is an aromatic polyamide composite material with a channel width of 1.651mm, and performs reverse osmosis on wastewater under the condition of an operating pressure of 2.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com