A zero-discharge treatment method and device for high-ammonia-nitrogen wastewater resource recycling by membrane aeration and membrane absorption coupling process

A technology of membrane aeration and membrane absorption, applied in water/sewage treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of long running time, complex process requirements, slow processing time, etc., and achieve construction investment Low cost, improved processing efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

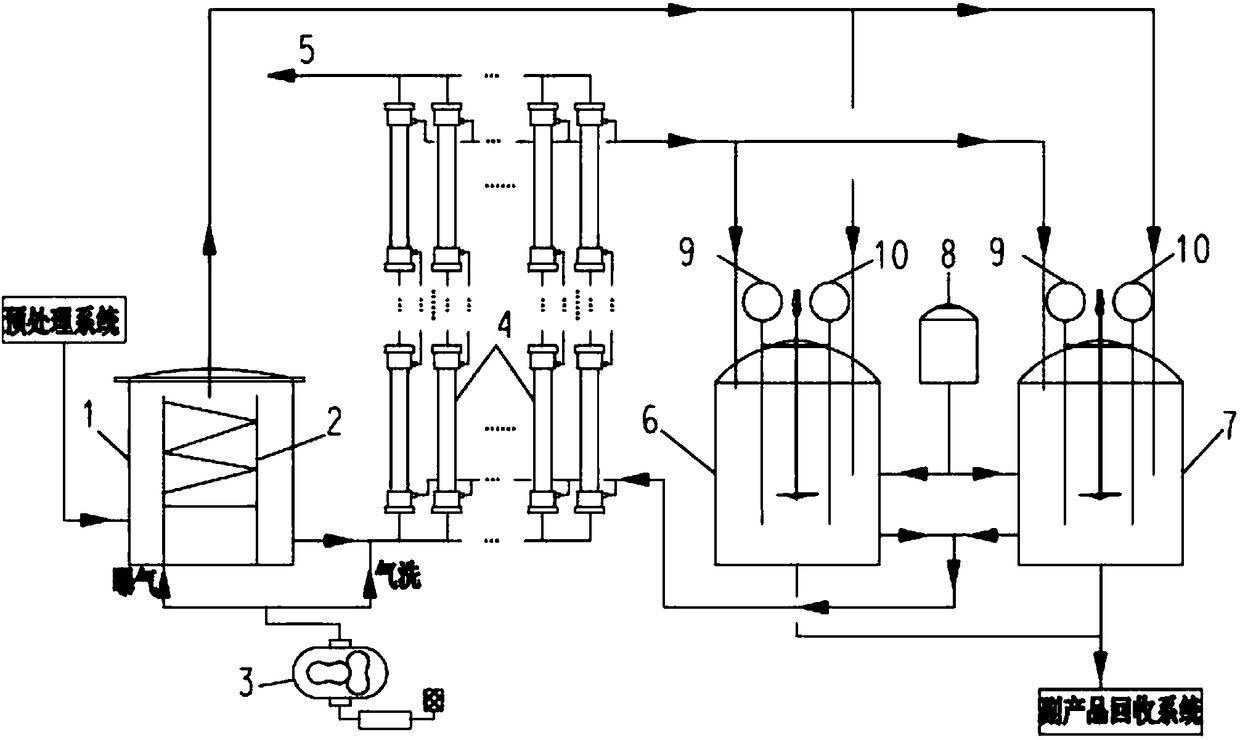

[0041] The combined process of membrane aeration and membrane absorption is used to treat coal chemical wastewater with an ammonia nitrogen concentration of 5000mg / L per tonne.

[0042] (1) Pretreatment process: Deoiling the high ammonia nitrogen stock solution mainly through coalescing materials, so that the oil content in the water is lower than 5ppm, and removing impurities from the ammonia nitrogen stock solution through a disc filter, so that the SS entering the membrane aeration system is lower than 10mg / L. The ammonia nitrogen concentration of the water after pretreatment is 5000mg / L.

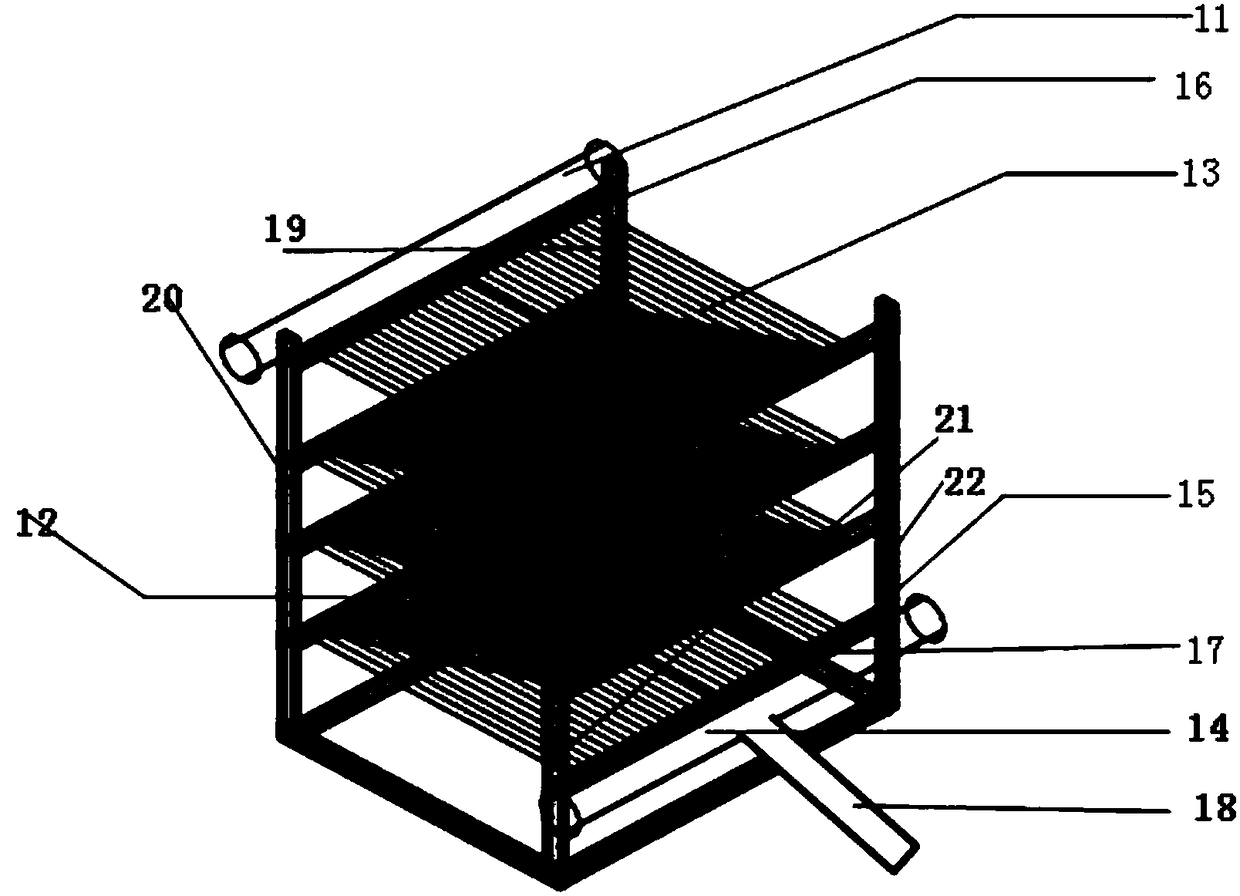

[0043] (2) Membrane aeration system: The pretreated high-ammonia nitrogen wastewater is passed into a well-sealed membrane aeration tank, and the membrane aeration system uses a hydrophobic hollow fiber membrane. The concentration of ammonia nitrogen through the membrane aeration system will be 2000mg / L.

[0044] (3) Membrane absorption system: pump the high-ammonia nitrogen wastewater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com