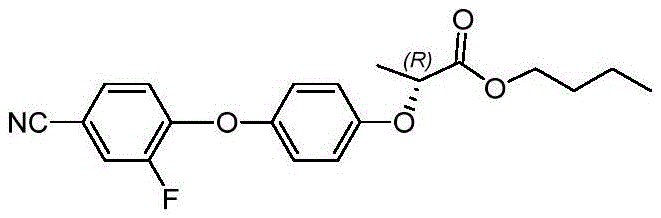

Preparation method of cyhalofop-butyl

A technology of cyhalofop-ethyl and diflubenil, which is applied in the field of preparation of cyhalofop-ethyl, can solve the problems of unrecoverable by-products of toluenesulfonic acid, racemization of the product configuration, and affecting product quality, etc., and achieve the reduction of three wastes Emissions, improved reaction selectivity, and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 A kind of preparation method of cyhalofop-methyl, comprises the following steps:

[0038] 1) etherification reaction

[0039]Put 100mL of N,N-dimethylacetamide, 50g of potassium carbonate, 5g of triethylenediamine and 60.3g of phase transfer catalyst 18-crown into a 250mL four-necked flask, and then put (R)-2-(4 26g (0.14mol) of -hydroxyphenoxy)propionic acid, a large number of bubbles are produced; after (R)-2-(4-hydroxyphenoxy)propionic acid is fed, add 20g of 3,4-difluorobenzonitrile (0.14mol), then the temperature was raised to 60° C., and the reaction was incubated for 3 hours, and the reaction ended. Distill under reduced pressure to remove the solvent, drop to room temperature and add 150 mL of water to dissolve, adjust the pH value to 4-5 with 15% dilute hydrochloric acid, stir to precipitate a solid, and filter to obtain (R)-2-[4-(2-fluoro-4-carbonitrile base)-phenoxy]-propionic acid for subsequent use.

[0040] 2) Esterification reaction

[00...

Embodiment 2

[0043] Embodiment 2 A kind of preparation method of cyhalofop-methyl, comprises the following steps:

[0044] 1) etherification reaction

[0045] Put 100mL of N,N-dimethylacetamide, 40g of potassium carbonate, 0.3g of hexamethylenetetramine and 3g of phase transfer catalyst tetrabutylammonium bromide into a 250mL four-necked flask, and then put (R)- 26g (0.14mol) of 2-(4-hydroxyphenoxy)propionic acid, a large number of bubbles are produced; after the feeding of (R)-2-(4-hydroxyphenoxy)propionic acid is completed, add 3,4-di Fluorobenzonitrile 22g (0.16mol), then heated up to 90°C, kept the temperature for 2 hours, and the reaction ended. Distill under reduced pressure to remove the solvent, drop to room temperature and add 250mL of water to dissolve, adjust the pH value to 3-4 with 30wt.% dilute sulfuric acid, stir to precipitate a solid, filter to obtain (R)-2-[4-(2-fluoro-4- Nitrile)-phenoxy]-propionic acid for later use.

[0046] 2) Esterification reaction

[0047] In a...

Embodiment 3

[0049] Embodiment 3 A kind of preparation method of cyhalofop-methyl, comprises the following steps:

[0050] 1) etherification reaction

[0051] Put 100mL of N,N-dimethylacetamide, 40g of potassium carbonate, 1g of diazabicyclo and 0.5g of phase transfer catalyst benzyltriethylamine into a 250mL four-neck flask, and then put (R)-2- (4-hydroxyphenoxy) propionic acid 26g (0.14mol), there is a large amount of bubbles to produce; wait for (R)-2-(4-hydroxyphenoxy) propionic acid to feed in, then drop into 3,4-difluorobenzene 20 g (0.14 mol) of nitrile, and then the temperature was raised to 85° C., and the reaction was kept for 2 hours, and the reaction was completed. Remove the solvent by distillation under reduced pressure, add 250 mL of water to dissolve at room temperature, adjust the pH value to 3-4 with 30% dilute phosphoric acid, stir to precipitate a solid, and filter to obtain (R)-2-[4-(2-fluoro-4-carbonitrile base)-phenoxy]-propionic acid for subsequent use.

[0052] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com