A long-chain alkyl quaternary ammonium salt monomer, its preparation method and associated polymer

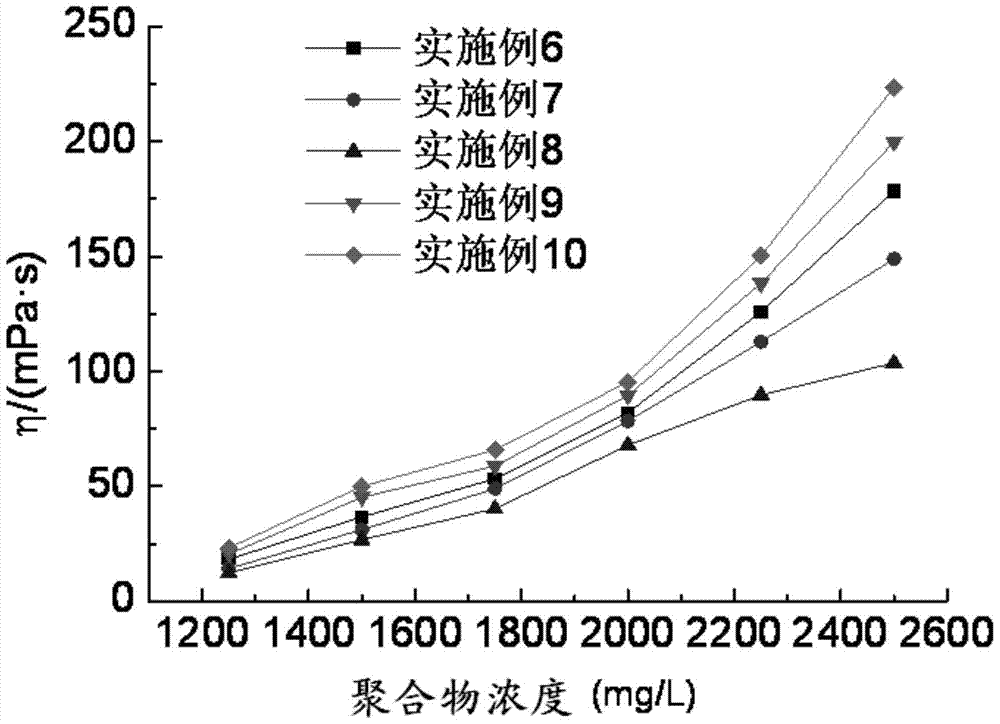

A technology for quaternary ammonium salt monomers and associative polymers, which is applied in the field of long-chain alkyl quaternary ammonium salt monomers, its preparation method and associative polymers, and can solve the problems of poor viscosity-increasing performance, poor salt resistance, and high temperature resistance gender issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

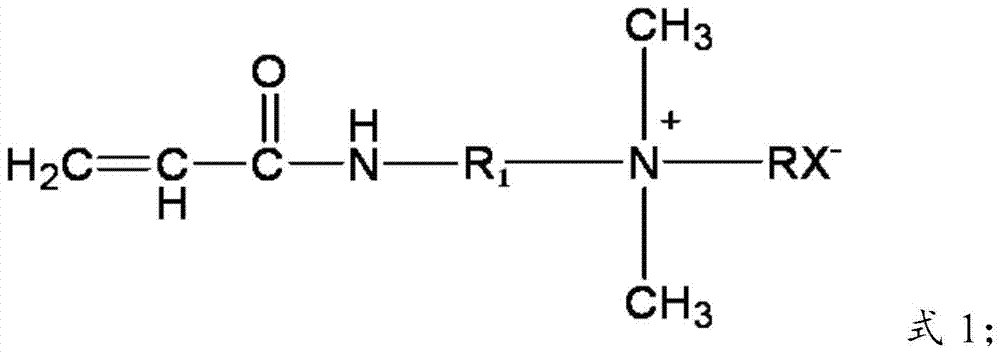

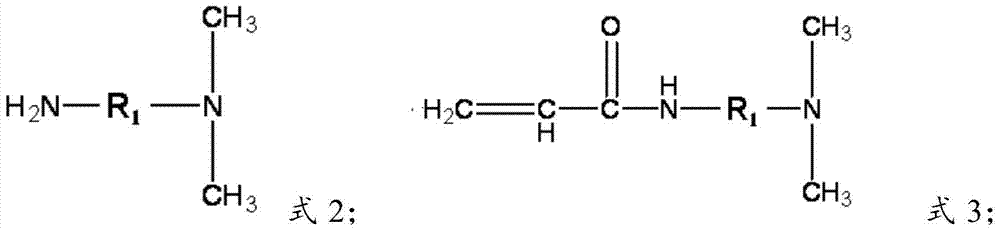

[0040] The present invention also provides a kind of preparation method of long chain alkyl quaternary ammonium salt monomer, comprises the following steps:

[0041] A) reacting acryloyl chloride and the compound shown in formula 2 to obtain the compound shown in formula 3;

[0042]

[0043] B) reacting the compound shown in formula 3 obtained in the step A) with the halogenated hydrocarbon RX to obtain the long-chain alkyl quaternary ammonium salt monomer shown in formula 1;

[0044]

[0045] In formula 1, R 1 is an arylene group, R is a C8-C20 alkyl group, and X is a halogen.

[0046]

[0047] In the present invention, the reaction of step A) is preferably carried out according to the reaction equation shown in formula 7. In the present invention, the compound shown in formula 3 is obtained by mixing acryloyl chloride and the compound shown in formula 2 in a solvent for reaction. In the present invention, preferably, the compound shown in formula 2 and acryloyl ch...

Embodiment 1

[0071] The synthesis of embodiment 1.(4-acrylamido) phenyl dodecyl dimethyl ammonium bromide

[0072] Step 1: In a four-neck flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen protection device, follow n(N,N-dimethyl-p-phenylenediamine): n(dimethyl Formamide (DMF)=1:2, add 102.5g N,N-dimethyl-p-phenylenediamine and 110.09g DMF, then add 15.0g sodium carbonate powder (as an acid-binding agent, react with HCl, one of the products, to promote the reaction Forward), under stirring conditions, the temperature of the system is controlled by an ice-water bath at -5~5°C, according to n(N,N-dimethyl-p-phenylenediamine):n(acryloyl chloride)=1:1.2, using a constant Slowly add the acryloyl chloride solution consisting of 81.77g of acryloyl chloride and 66.05g of DMF solvent into the pressure dropping funnel. The molar ratio of the two is 1:1. The yellowish intermediate product N,N-dimethyl-(4-acrylamido)phenylamine was fi...

Embodiment 2

[0078] Embodiment 2. (4-acrylamido) the synthesis of phenyl dodecyl dimethyl ammonium chloride

[0079] Step 1 is the same as Example 1

[0080] Step 2: In a four-necked flask equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure dropping funnel, and a nitrogen protection device, follow n (intermediate product): n (ethyl acetate): n (chlorododecane )=1:2.5:1.2, add 109.54g intermediate product, 126.86g ethyl acetate, 154.12g chlorododecane successively, pass into N2 protection, under stirring condition, temperature rises to 65 ℃, constant temperature reaction 36h, pass The solvent ethyl acetate was removed by a rotary evaporator to obtain a slightly yellow viscous liquid, which was stored in a refrigerator to form a light yellow solid, which was washed 2 to 3 times with ether, and the product was dried in a vacuum oven at 60°C for 8 hours to obtain 189.02g of (4-acrylamido) phenyl dodecyl dimethyl ammonium chloride, as shown in formula 1-2, yield 83....

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com