Composite microsphere marker for conducting fluorescent marking on rear earth and preparation method of composite microsphere marker

A rare earth fluorescence, composite microsphere technology, applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of short fluorescence lifetime and low sensitivity, achieve long fluorescence lifetime, improve resolution, and enhance specificity. Effects of Sex and Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

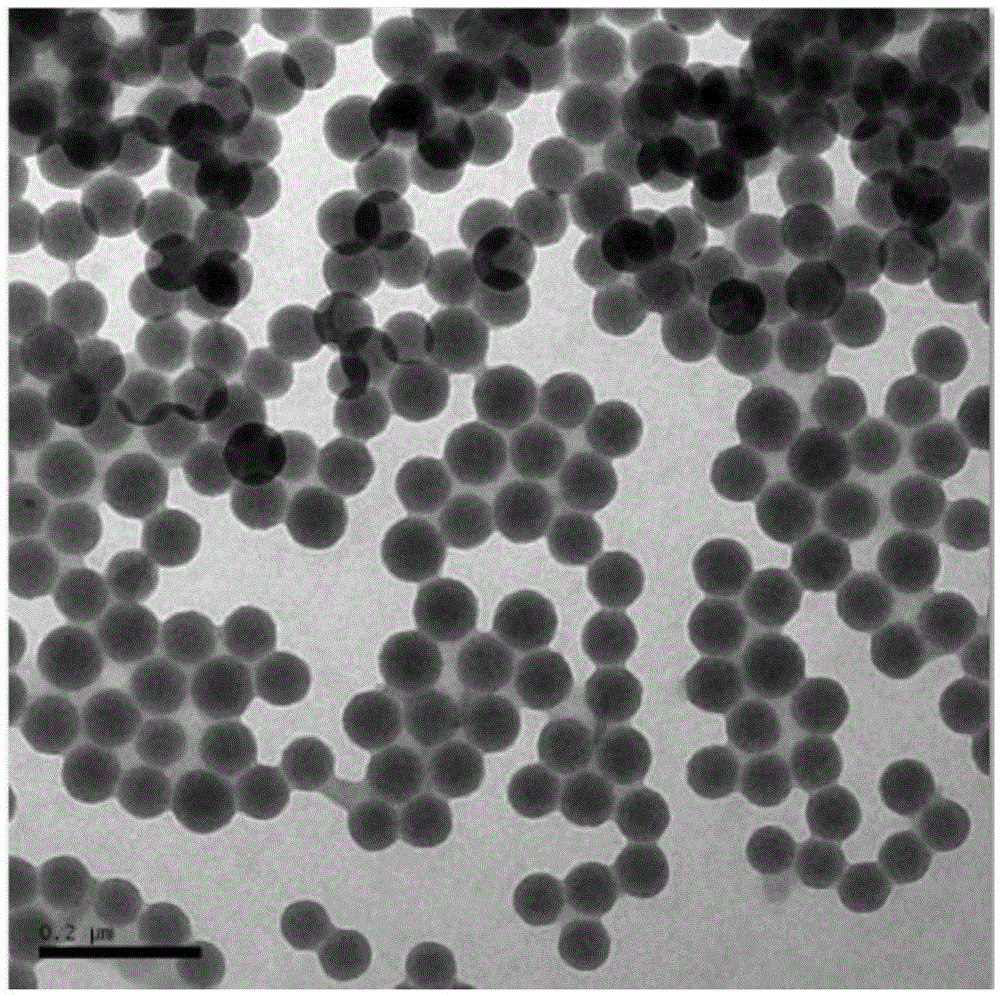

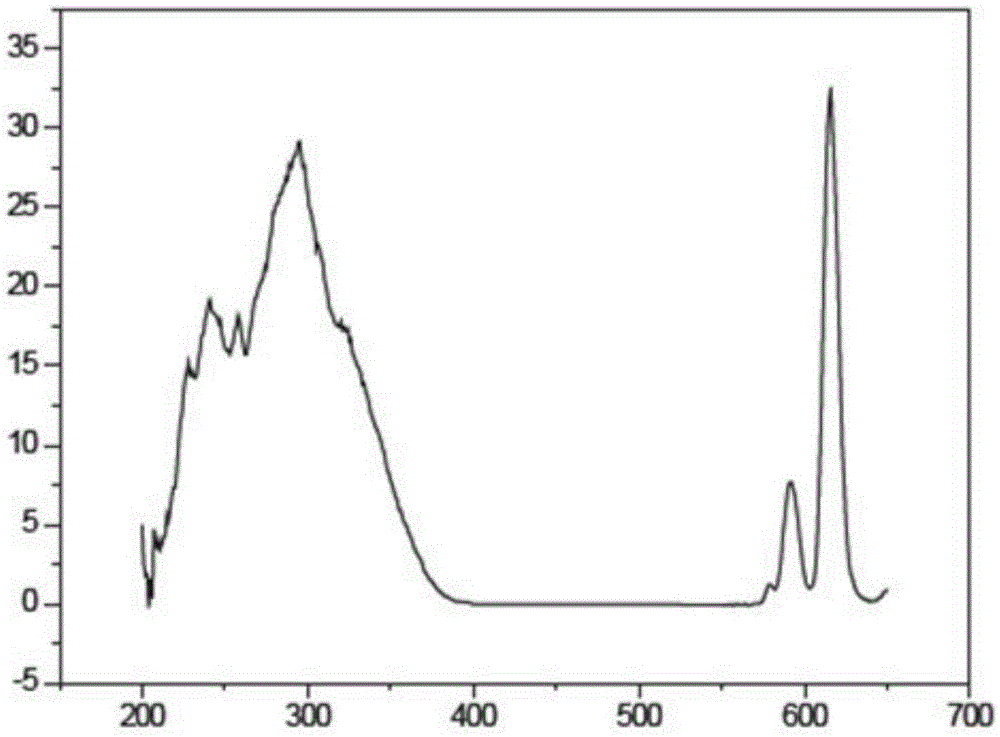

[0040] Specific embodiment 1 prepares BHHCT-Eu 3+ Fluorescent Nanospheres:

[0041] (1), raw material preparation:

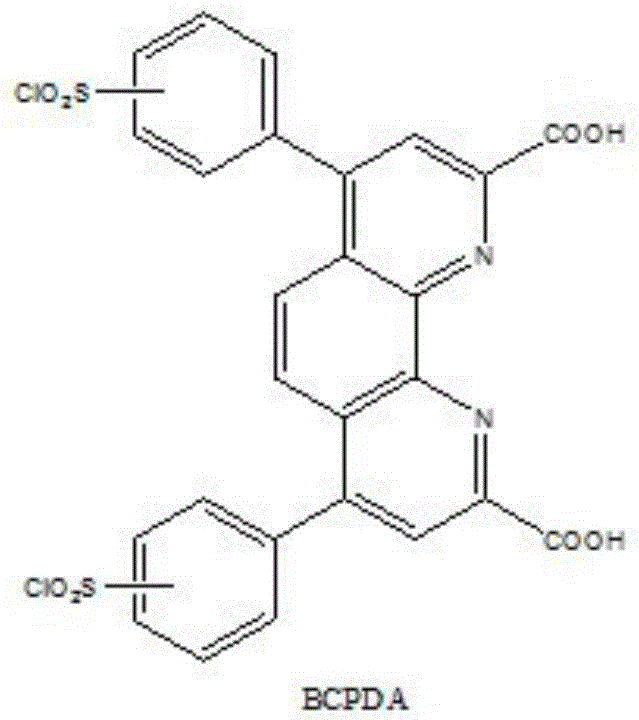

[0042] Prepare raw materials by weight: 15g polyvinylpyrrolidone (PVP), 0.03g potassium persulfate (KPS), 8g styrene (St), 80ml ethanol or water and 4,4,-bis(1,1,1,2,2 ,3,3-Heptafluoro-4,6-hexanedionyl)chlorosulfo-o-terphenyl (BHHCT);

[0043] (2), preparation of composite microspheres:

[0044] 4,4,-Bis(1,1,1,2,2,3,3-heptafluoro-4,6-hexanedionyl)chlorosulfo-o-terphenyl (BHHCT) is a trilobal β-diketone compounds can form stable complexes with Eu3+, and can emit strong fluorescence under the excitation of ultraviolet light; BHHCT has poor water solubility, good solubility in ethanol, and its own -SOCl2 group Groups can react with amino groups to form covalent bonds; use materials such as styrene preparation to prepare polystyrene nano-microsphere cores, and use aminosilane to introduce amino groups on the surface of microspheres, and BHHCT-Eu3+ can be marked ...

specific Embodiment 2

[0051] Specific embodiment 2 prepares BHHCT-Eu 3+ Fluorescent Nanospheres:

[0052] (1), raw material preparation:

[0053] Prepare raw materials by weight: 30g polyvinylpyrrolidone (PVP), 0.10g potassium persulfate (KPS), 12g styrene (St), 120ml ethanol or water and 4,4,-bis(1,1,1,2,2 ,3,3-Heptafluoro-4,6-hexanedionyl)chlorosulfo-o-terphenyl (BHHCT);

[0054] (2), preparation of composite microspheres:

[0055] 1), preparation of aminated nanospheres:

[0056] Dissolve 30g of polyvinylpyrrolidone (PVP), 0.10g of potassium persulfate (KPS), 12g of styrene (St), 120ml of ethanol or water medium and place it in an ultrasonic reactor, pass nitrogen gas to remove the oxygen in the system, and turn on the ultrasonic wave The generator performs a polymerization reaction, and obtains a polystyrene nanosphere dispersion after 10 hours of reaction;

[0057] Collect polystyrene nanospheres by centrifugation, suspend them with 5 mL of absolute ethanol, add 5 μL of aminosilane, stir ...

specific Embodiment 3

[0061] Specific embodiment 3 prepares BHHCT-Eu 3+ Fluorescent Nanospheres:

[0062] (1), raw material preparation:

[0063] Prepare raw materials by weight: 25g polyvinylpyrrolidone (PVP), 0.06g potassium persulfate (KPS), 10g styrene (St), 100ml ethanol or water and 4,4,-bis(1,1,1,2,2 ,3,3-Heptafluoro-4,6-hexanedionyl)chlorosulfo-o-terphenyl (BHHCT);

[0064] (2), preparation of composite microspheres:

[0065] 1), preparation of aminated nanospheres:

[0066] Add 25g of polyvinylpyrrolidone, 0.06g of potassium persulfate, and 10g of styrene into 100mL of ethanol or water medium to dissolve and place them in an ultrasonic reactor, pass nitrogen to remove the oxygen in the system, and turn on the ultrasonic generator for polymerization. After 8 hours, polystyrene nanosphere dispersion liquid was obtained;

[0067] Collect polystyrene nanospheres by centrifugation, suspend them with 5 mL of absolute ethanol, add 5 μL of aminosilane, stir and react at room temperature for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com