Preparation method of three-dimensional hierarchical porous nitrogen-doped graphene and product

A nitrogen-doped graphene, hierarchical porous technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems affecting the performance of porous graphene, save template costs and process steps, have a wide range of sources, maintain The effect of internal topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

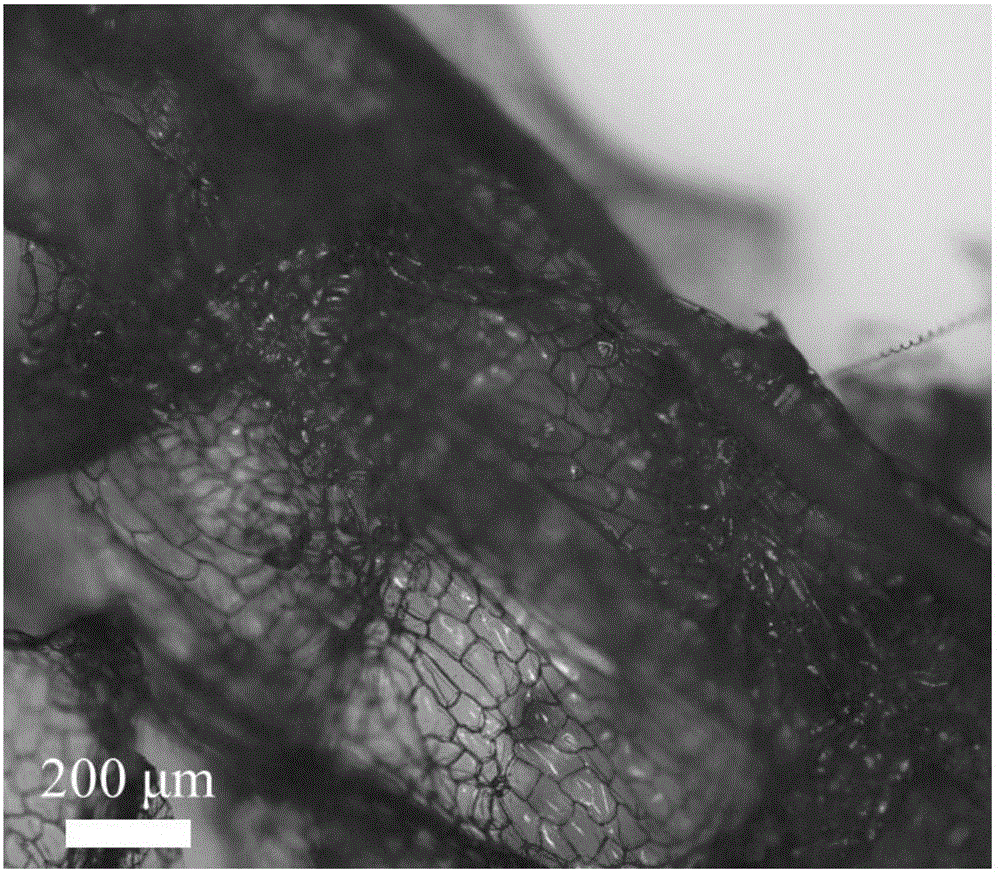

[0047] 1) Taking duckweed (its microstructure as figure 1 As shown in the figure, it can be seen from the figure that the duckweed itself contains a three-dimensional porous structure) as a raw material, wash the duckweed, soak it in ethanol solution for 48 hours, and then take it out; then place it in a tube furnace for carbonization at 1000°C under an argon atmosphere , keep warm for 2h, at 2℃·min -1 heating rate heating;

[0048] 2) Weigh 5g of the sample in step 3), put it into 10g of concentrated sulfuric acid, and then add 5g of NaNO 3 Solid and 20g KMnO 4 The solid was placed in a water bath at 30°C and stirred for 30 minutes, then an excess of 30 g K was added 2 CO 3 Continue to stir the solid for 30 minutes, and then fully dry it in a common drying oven;

[0049] 3) Place the consolidated block obtained in step 2) in a tube furnace, and activate it by raising the temperature to 700°C under an inert gas protective atmosphere. The activation holding time is 1h, and...

Embodiment 2

[0054] 1) Wash the straw, soak it in ethanol solution for 52 hours, take it out, and then place it in a tube furnace for carbonization at 900°C under an argon atmosphere. -1 heating rate heating;

[0055] 2) Weigh 5g of the sample in step 1), and add 7.5g of NaNO to 15g of concentrated sulfuric acid 3 Solid and 25g KMnO 4 The solid was placed in a water bath at 20°C and stirred for 20 minutes, then an excess of 55 g K was added 2 CO 3 Continue to stir the solid for 40 minutes, and then fully dry it in a common drying oven;

[0056] 3) Put the consolidated block obtained in step 2) in a tube furnace, and activate it by raising the temperature to 800°C under an inert gas protective atmosphere. The activation holding time is 1.5h, and the heating rate is 7°C·min -1 ;

[0057] 4) Grinding the product obtained in step 3) to 0.5MH 2 SO 4 Pickling at room temperature for 4 hours, suction filtration, and washing with water until neutral;

[0058] 5) The sample obtained in step...

Embodiment 3

[0061] 1) Wash the peanut shells, soak them in ethanol solution for 56 hours, take them out, and place them in a tube furnace for carbonization at 1100°C under a nitrogen atmosphere. -1 heating rate heating;

[0062] 2) Weigh 5g of the sample in step 1), and add 10g of NaNO to 10g of concentrated sulfuric acid 3 Solid and 28g KMnO 4 The solid was placed in a water bath at 40°C and stirred for 40 minutes, then an excess of 40 g K was added 2 CO 3 Continue to stir the solid for 20 minutes, and then fully dry it in an ordinary drying oven;

[0063] 3) Put the consolidated block obtained in step 2) in a tube furnace, and activate it by raising the temperature to 900°C under an inert gas protective atmosphere. The activation holding time is 2h, and the heating rate is 6°C·min-1 ;

[0064] 4) Grinding the product obtained in step 3) to 0.5MH 2 SO 4 Pickling at room temperature for 8 hours, suction filtration, and washing with water until neutral;

[0065] 5) The sample obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com