Preparation method and application of perylene bisimide based organometallic polymer with visible-light photocatalytic performance

A perylene imide and visible light technology, applied in the field of photocatalytic materials, can solve problems such as difficult promotion, high price, and scarce sources, and achieve the effects of easy synthesis, simple synthesis, and difficult dissolution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

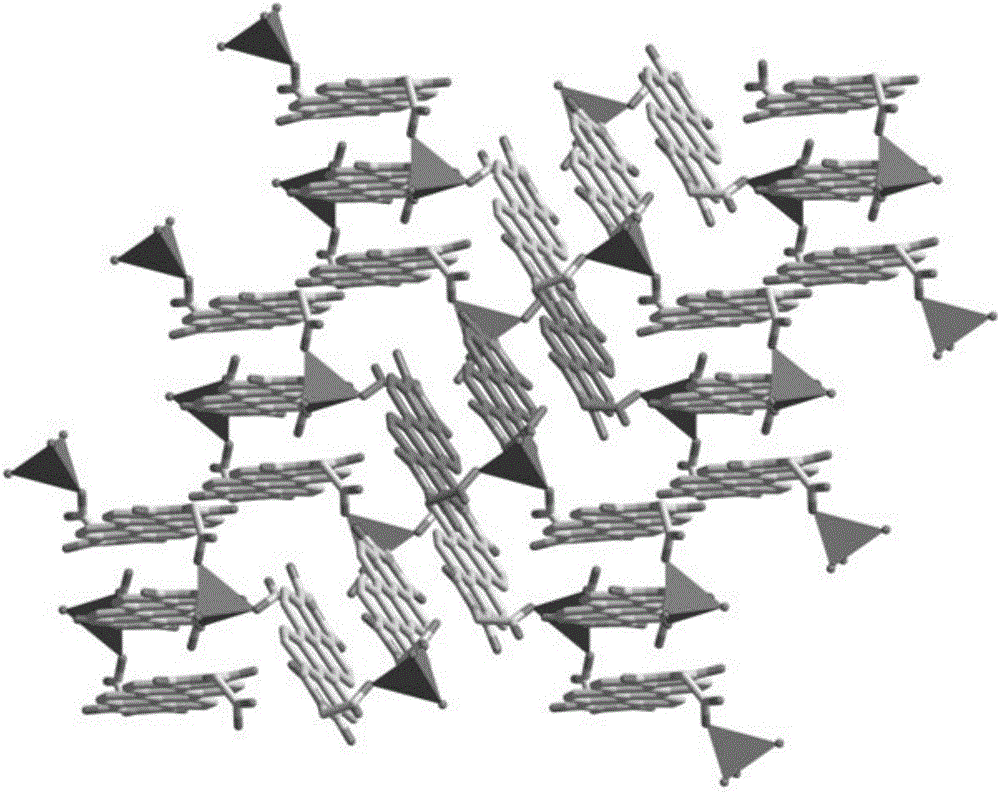

[0028] The peryleneimide derivative C 28 h 14 N 2 o 8 (5mg, 0.01mmol), Zn(ClO 4 ) 2 ·6H 2 O (3.7mg, 0.01mmol) was dissolved in a mixed solvent of 3mL N,N-dimethylformamide and 7mL water, and NaOH (6mg, 0.1mmol) was added to adjust the solution to weak basicity. The obtained mixture was then placed in an oven, fired at 100°C for 72 hours, closed the oven, cooled to room temperature, red to black diamond-shaped block crystals were precipitated, filtered, and dried to obtain the target material Zn-PDI with a yield of about 44 %. Elemental analysis (%) for C 45 h 29 N 4 o 15 Zn: C, 58.05; H, 3.14; N, 6.02. Found: C, 58.58; H, 3.08; N, 6.23. The schematic diagram of the obtained two-dimensional structure of the target material is as follows figure 1 shown.

Embodiment 2

[0030] Zn-PDI catalyzes the dehalogenation reaction of aryl halides under visible light: aryl halides (0.05mmol), Zn-PDI (5mol%), and 3mL of dry DMF solution are added to a 10mL dry transparent glass tube, and poured into the glass tube Nitrogen (N 2 ) about 20 minutes to remove the oxygen in the reaction tube and the solvent. In pass N 2 The electron sacrificial agent triethylamine (3.6 mmol) was added during the process. The reaction was irradiated with a 455nm blue LED lamp at 40°C. The progress of the reaction was monitored by the gas phase. After the reaction is completed, the catalyst is centrifugally filtered, and the filtrate is directly obtained by the internal standard method of the gas phase after dilution, such as Image 6 shown.

Embodiment 3

[0032] Zn-PDI catalyzes the dehalogenation of aryl halides under visible light and is used for the C-H arylation reaction with N-methylpyrrole: aryl halides (0.1 mmol), Zn-PDI (5mol%), and 3 mL of dry DMF solution are added into a 10mL dry transparent glass tube, and pass nitrogen gas into the glass tube (N 2 ) about 20 minutes to remove the oxygen in the reaction tube and the solvent. In pass N 2 Electron sacrificial agents triethylamine (0.8 mmol) and N-methylpyrrole (2.5 mmol or 5.0 mmol) were added during the process. The reaction was irradiated with a 455nm blue LED lamp at 40°C. The progress of the reaction was monitored by the gas phase. After the reaction was complete, the reaction mixture was transferred to a separatory funnel, and 10 mL of deionized water and 2 mL of saturated saline were added. The mixture was extracted with ethyl acetate (3 x 10 mL) and the resulting organic layer was dried, filtered and concentrated in vacuo. Finally, use ethyl acetate / petrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com