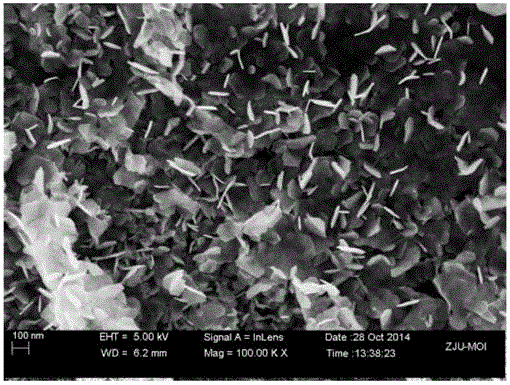

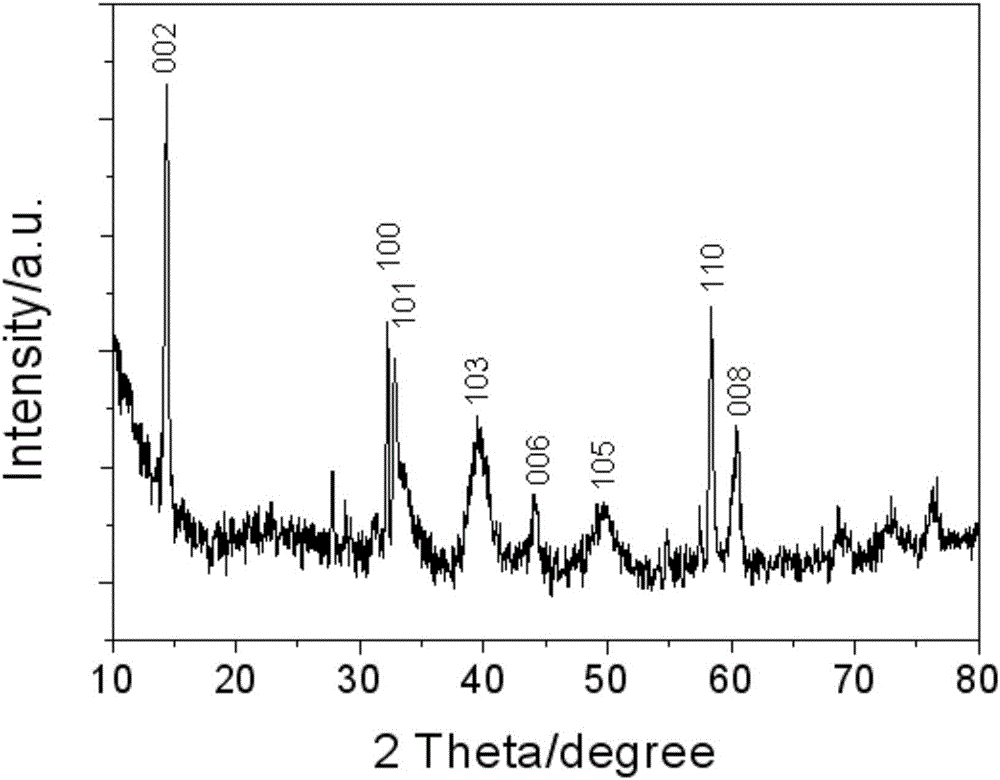

Preparation method of graphene/molybdenum disulfide composite material

A molybdenum disulfide and composite material technology, which is applied to secondary batteries, electrochemical generators, active material electrodes, etc., can solve the problems of cumbersome steps, difficult to disperse, easy to agglomerate, etc., and achieve the effect of simple synthesis steps and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Prefabrication of raw materials

[0028] Take by weighing 0.8g glucose, 0.5g ammonium tetrathiomolybdate, after fully mixing in glove box, place in agate mortar and grind for 30min, obtain mixture A; Take by weighing 11.5g sodium chloride and 11.5g potassium chloride, After mixing thoroughly, place it in a ball mill and grind for 30 minutes to obtain mixture B; mix mixtures A and B, and place them in a square porcelain boat. The total amount of the mixture should not exceed two-thirds of the total amount of the porcelain boat.

[0029] 2. Material pretreatment

[0030] The mixture obtained in step 1 was placed in a vacuum drying oven, and heat-treated at 80°C for 10;

[0031] 3. Environmental reaction of molten salt

[0032] Place the mixture obtained in step 2 in the middle of the tube furnace tube, pass through nitrogen protection, heat up to 950 °C at a heating rate of 5 °C / min, after reaching the target temperature, keep it warm for 30 min, cool naturally to ro...

Embodiment 2

[0036] 1. Prefabrication of raw materials

[0037] Take by weighing 0.1g glucose, 0.1g ammonium tetrathiomolybdate, after fully mixing in the glove box, place in the agate mortar and grind for 50min, obtain mixture A; Take by weighing 11.4g sodium chloride and 2.8g potassium chloride, After mixing thoroughly, place it in a ball mill and grind for 50 minutes to obtain mixture B; mix mixtures A and B, and place them in a square porcelain boat. The total amount of the mixture should not exceed two-thirds of the total amount of the porcelain boat.

[0038] 2. Material pretreatment

[0039] The mixture obtained in step 1 was placed in a vacuum drying oven, and after heat treatment at 150° C. for 20 h;

[0040] 3. Environmental reaction of molten salt

[0041] Place the mixture obtained in step 2 in the middle of the tube furnace tube, pass through nitrogen protection, heat up to 1000 °C at a heating rate of 20 °C / min, after reaching the target temperature, keep it warm for 40 min...

Embodiment 3

[0045] 1. Prefabrication of raw materials

[0046] Take by weighing 0.5g glucose, the ammonium chloride of 1g, 0.05g ammonium tetrathiomolybdate, after fully mixing in glove box, place in the agate mortar and grind 60min, obtain mixture A; Take by weighing 13.5g sodium chloride and 11.5g of potassium chloride, mixed thoroughly and placed in a ball mill to grind for 60 minutes to obtain mixture B; mix mixtures A and B and place in a square porcelain boat, the total amount of the mixture should not exceed 2 / 3 of the total amount of the porcelain boat.

[0047] 2. Material pretreatment

[0048] Place the mixture obtained in step 1 in a vacuum drying oven, heat-treat at 200°C for 30 hours, and take it out after naturally cooling down to room temperature;

[0049] 3. Environmental reaction of molten salt

[0050] Place the mixture obtained in step 2 in the middle of the tube furnace tube, pass through nitrogen protection, heat up to 1300 °C at a heating rate of 30 °C / min, after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com